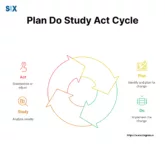

Plan Do Study Act Cycle for Lean Six Sigma & Continuous Improvement

Making process changes that actually stick presents a significant challenge, particularly within the complex systems common in Lean Six Sigma and other operational environments. How can organizations ensure that improvements lead to sustained gains rather than fading over time? A proven method involves adopting a structured, iterative approach. The plan do study act cycle provides a foundational […]