The Guide to Supply Chain Risk Management: Strategies for a Resilient Future

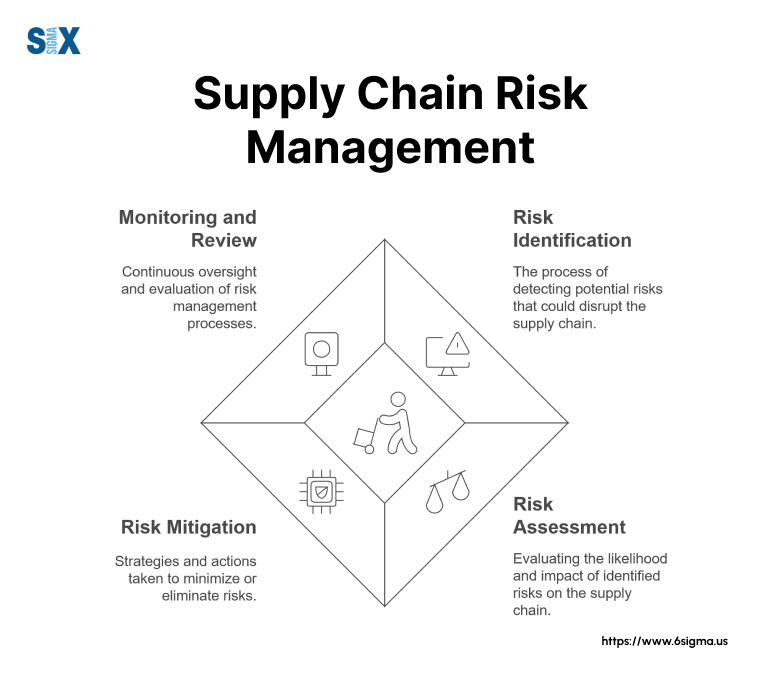

Supply chain risk management (SCRM) is your organization’s strategic approach to identifying, assessing, and reducing potential disruptions in your supply network.

Think of it as your business’s insurance policy against unexpected events that could halt operations or impact your bottom line.

Why SCRM (Supply Chain Risk Management) Matters Now More Than Ever

The global supply chain industry has shifted dramatically. COVID-19, trade wars, and climate events have shown us just how vulnerable supply chains can be.

Here’s what we’re seeing in 2024:

- 89% of companies experienced a supplier risk event in the past year

- Supply chain disruptions cost businesses an average of $184 million per incident

- Only 21% of organizations report having highly resilient supply networks

Key Highlights

- Complete SCRM implementation guide for business leaders

- Risk identification and mitigation strategies explained

- Technology’s role in modern supply chains

- Cross-functional approach to risk management

- Standards and best practices for SCRM

What Is Supply Chain Risk?

Supply chain risk is anything that could disrupt your business operations – from a delayed shipment to a major factory shutdown.

These risks pop up more often than you’d expect, and they can hit your bottom line hard.

The Four Types of Supply Chain Risks You Need to Know

1. Internal Risks

Internal risks emerge from within your organization’s operations and processes. These typically start with manufacturing process breakdowns, which can cascade through your entire production line.

IT system failures pose another significant threat, especially as businesses become more digitally dependent.

Your workforce stability also plays a crucial role – staff shortages and high turnover can severely impact operations.

Quality control issues often surface when processes aren’t properly monitored or when standards slip, leading to product defects and customer dissatisfaction.

Cash flow problems round out these internal challenges, potentially affecting your ability to maintain operations or invest in necessary improvements.

2. External Risks

External risks come from the world beyond your organization’s control. Natural disasters can strike without warning, disrupting supply lines and damaging infrastructure.

Political changes, whether domestic or international, can reshape trade relationships overnight. Economic shifts, from recession to inflation, directly impact your bottom line.

When supplier bankruptcies occur, they can leave you scrambling for alternatives.

Market fluctuations affect everything from raw material costs to consumer demand, making planning and forecasting increasingly challenging.

3. Network Risks

Network risks arise from the interconnected nature of modern supply chains. Transportation delays have become increasingly common, affecting delivery schedules and customer satisfaction.

Communication gaps between different parts of your supply chain can lead to misunderstandings and missed opportunities. Inventory mismanagement often results in either stockouts or excess inventory, both costly scenarios.

Supplier relationship issues can develop when expectations aren’t met or communication breaks down.

Logistics bottlenecks, whether at ports, warehouses, or distribution centers, can create ripple effects throughout your entire supply chain.

4. Environmental Risks

Environmental risks have taken center stage in recent years. New regulations frequently emerge, requiring rapid adaptation and compliance.’

Sustainability requirements from both regulators and customers demand significant operational changes.

Resource shortages, whether water, energy, or raw materials, can threaten production continuity. Climate change impacts, from severe weather events to changing growing seasons, affect supply chain reliability.

Social responsibility demands from stakeholders require careful attention to ethical sourcing and fair labor practices, adding another layer of complexity to supply chain management.

Identify and eliminate supply chain risks with our Root Cause Analysis training program.

Common Supply Chain Weak Points

Let’s look at where supply chains often break down:

- Single-source suppliers

- Poor visibility beyond tier-1 suppliers

- Outdated technology systems

- Weak quality control processes

- Limited risk assessment procedures

The Impact

Take the 2021 semiconductor shortage – it showed how one missing component could halt production across multiple industries.

Car manufacturers lost billions in revenue, and consumers faced months-long waits for new vehicles.

Supply Chain Challenges

The risk landscape keeps shifting.

Here’s what supply chain managers face in 2024:

- AI and automation adoption

- Growing ESG requirements

- Geopolitical tensions

- Cyber security threats

- Skilled labor shortages

Key Risk Indicators to Watch

- Supplier financial health

- On-time delivery rates

- Quality metrics

- Production capacity

- Market conditions

- Weather patterns

- Political stability

Tools for Risk Assessment

- Supplier scorecards

- Risk heat maps

- Financial modeling

- Scenario planning

- Real-time monitoring systems

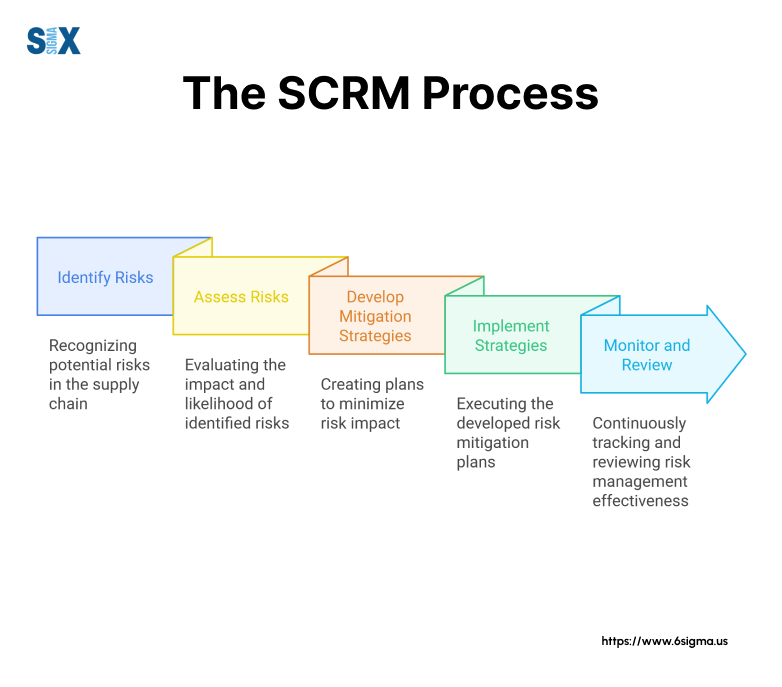

The SCRM (Supply Chain Risk Management) Process: Your Step-by-Step Guide

Managing supply chain risk isn’t a one-time task – it’s an ongoing process that needs regular attention and updates. Here’s how successful companies tackle it:

Step 1: Risk Identification

Risk identification begins with spotting potential problems before they impact your business.

Start by mapping your entire supply chain to understand every connection and dependency.

Engage in meaningful conversations with your suppliers and team members who often spot early warning signs of potential issues.

Review your history of disruptions – past problems often provide valuable insights into future risks.

Stay current with industry reports that highlight emerging threats and opportunities.

Step 2: Risk Assessment

Risk assessment requires careful evaluation since not all risks pose equal threats to your business.

Begin by rating each risk’s likelihood of occurrence and calculating its potential financial impact on your operations.

Consider how each risk might disrupt your operations and estimate the time needed for recovery.

Don’t forget to assess potential damage to your company’s reputation – sometimes the most expensive cost isn’t financial.

Use proven tools like risk matrices and impact scales to standardize your assessments.

Probability assessments, cost-benefit analysis, and scenario modeling help create a complete picture of each risk’s potential impact.

Step 3: Risk Mitigation

Risk mitigation involves choosing the right strategy for each identified risk.

For high-threat situations, consider avoiding the risk entirely by switching to safer suppliers or modifying processes that pose unnecessary dangers.

When appropriate, transfer risks through insurance coverage or by partnering with third-party logistics providers who can share the burden.

Reduce impact by building buffer inventory and developing relationships with backup suppliers before you need them.

For minor risks that are part of normal business operations, accept them while preparing your team through training and setting aside emergency funds for quick response.

Step 4: Risk Monitoring and Review

Effective risk monitoring requires consistent attention at different intervals.

Daily monitoring should focus on immediate operational concerns like supplier performance, delivery schedules, and quality control reports.

Weekly reviews need to track broader indicators including market conditions, weather forecasts, and political developments that might affect your supply chain.

Monthly assessments provide opportunities to update your risk register, evaluate strategy effectiveness, and identify new risks that might have emerged.

Regular monitoring helps you stay ahead of potential problems and Process improvements to adjust your strategies before small issues become major disruptions.

Making Supply Chain Risk Management Work: Best Practices

- Assign clear ownership for each risk

- Set up regular review meetings

- Use data-driven decisions

- Keep documentation current

- Train your team regularly

Technology Tools That Helps with Supply Chain Risk Management (SCRM)

- Risk management software

- Real-time tracking systems

- Predictive analytics

- Supplier portals

- Communication platforms

The best SCRM process is one your team can actually follow. Start simple, then build up as you go.

Focus on your biggest risks first, and keep improving your process based on what works for your business.

Implement a robust risk assessment process with our FMEA certification program to identify and mitigate supply chain vulnerabilities

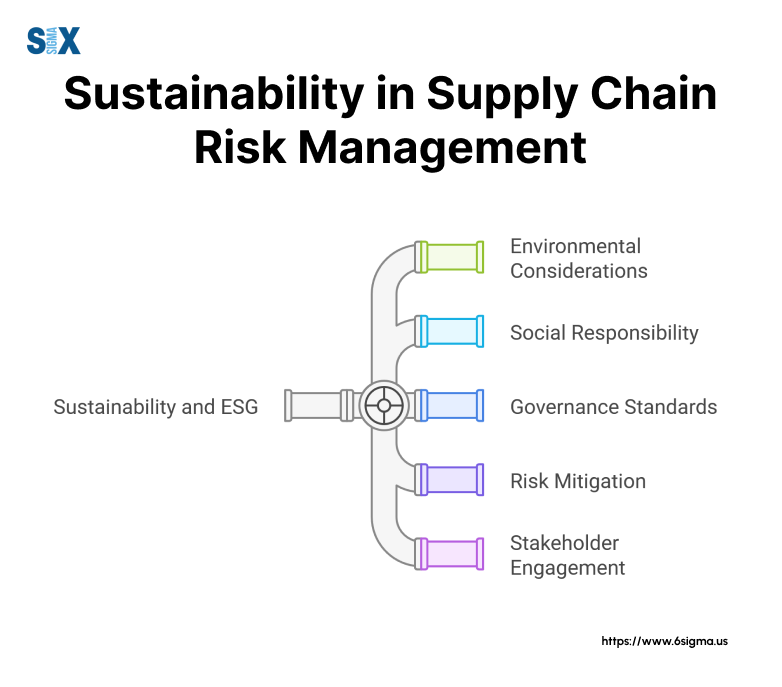

Sustainability and ESG in Supply Chain Risk Management

Environmental, Social, and Governance (ESG) factors now play a crucial role in supply chain risk management.

Let’s break down what this means for your business.

Environmental Impact on Your Supply Chain

Climate change isn’t just an environmental issue – it’s a business risk that affects your bottom line:

- Carbon footprint tracking

- Waste reduction goals

- Energy efficiency measures

- Water usage monitoring

- Raw material sourcing

Example: Nike faced backlash in 2021 when their suppliers contributed to deforestation. They quickly changed suppliers and strengthened their environmental standards.

Building Ethical Supply Chains

Your reputation depends on how well you manage these social factors:

Worker Rights:

- Fair wages

- Safe working conditions

- Reasonable hours

- No child labor

- Freedom of association

Community Impact:

- Local hiring practices

- Community development

- Cultural sensitivity

- Fair land use

- Noise and pollution control

Global Compliance and Governance in Supply Chain Risk Management

Stay ahead of regulations with these key focus areas:

Required Standards:

- ISO 14001 (Environmental)

- SA8000 (Social Accountability)

- ISO 45001 (Safety)

- GRI Standards (Reporting)

Compliance Tools:

- Supplier audits

- Documentation systems

- Training programs

- Reporting frameworks

- Verification processes

Making Sustainability Work for Your Business

Balance green initiatives with operational needs:

Short-term Actions:

- Energy-efficient equipment

- Waste reduction programs

- Local sourcing options

- Digital documentation

- Green packaging

Long-term Strategies:

- Renewable energy adoption

- Circular supply chains

- Sustainable transport

- Eco-friendly facilities

- Carbon neutral goals

Measuring ESG Success with Supply Chain Risk Management (SCRM)

Track these key metrics:

Environmental

Environmental metrics form the foundation of sustainable supply chain management. Carbon emissions tracking provides crucial insights into your climate impact and helps identify areas for reduction.

Water usage monitoring becomes increasingly critical as water scarcity affects more regions globally. Your waste reduction efforts should be measured consistently to ensure continuous improvement.

Energy efficiency metrics reveal opportunities for cost savings while supporting sustainability goals.

Material recycling rates demonstrate your commitment to circular economy principles and help identify opportunities to reduce raw material costs.

Social

Social metrics help gauge your organization’s impact on people and communities. Worker satisfaction scores offer insights into your workforce’s engagement and potential retention issues.

Community feedback provides valuable perspectives on your local impact and social license to operate.

Tracking safety incidents helps prevent future accidents and ensures regulatory compliance.

Labor compliance measurements protect your organization from legal issues and reputation damage.

Training hours tracking demonstrates your investment in workforce development and helps maintain skilled teams across your supply chain.

Governance

Governance metrics ensure your organization maintains high standards of operation. Regular audit results provide objective assessments of your processes and compliance levels.

Policy compliance tracking helps prevent regulatory issues before they arise. Reporting accuracy measurements ensure stakeholders receive reliable information for decision-making.

Stakeholder engagement metrics help maintain strong relationships with key partners. Risk assessment tracking enables proactive management of potential issues across your supply chain network.

Step towards sustainability with Cause and Effect Matrix training

Technology Solutions for ESG Management

- Carbon tracking software

- Supply chain mapping tools

- ESG reporting platforms

- Blockchain for transparency

- IoT for resource monitoring

Strong ESG practices don’t just reduce risk – they can create competitive advantages and open new market opportunities. Your customers, investors, and employees increasingly demand it.

I’ll help craft these sections while maintaining a professional yet accessible tone. Let me start with two of these sections to ensure they meet your requirements:

SCRM (Supply Chain Risk Management) for Small and Medium-Sized Enterprises

Small businesses face unique supply chain challenges. Here’s how to tackle them without breaking the bank.

Common SME Challenges

- Limited budget for risk management

- Fewer supplier options

- Less bargaining power

- Tight cash flow

- Resource constraints

Real Example: A local electronics manufacturer lost 40% of their revenue when their sole component supplier went bankrupt. They could have prevented this with basic risk management steps.

Budget-Friendly SCRM (Supply Chain Risk Management) Solutions

Start Small:

- Free supplier monitoring tools

- Basic risk assessment templates

- Industry partnership networks

- Government resources

- Open-source software

Quick Wins:

- Build emergency cash reserves

- Find backup suppliers

- Document key processes

- Cross-train employees

- Join industry groups

Smart Tech Solutions for SMEs

Affordable tools to get started:

- Cloud-based inventory tracking

- Free supplier databases

- Mobile apps for delivery tracking

- Social media monitoring

- Basic analytics tools

Human Factors in Supply Chain Risk

People make or break your risk management efforts. Here’s how to get everyone on board.

Building a Risk-Aware Culture

Key Elements:

- Clear communication channels

- Regular risk discussions

- Reward risk reporting

- Share success stories

- Learn from near-misses

Training Your Team on Supply Chain Risk Management (SCRM)

Essential Skills:

- Risk identification

- Basic analysis methods

- Response procedures

- Communication protocols

- Decision-making frameworks

Training Methods:

- On-the-job learning

- Online courses

- Team workshops

- Tabletop exercises

- Mentor programs

Managing Change in SCRM (Supply Chain Risk Management)

Step-by-Step Approach:

- Show why change matters

- Get early wins

- Share success stories

- Address concerns quickly

- Celebrate progress

Tip: Start with small changes that show quick results. Success breeds buy-in from skeptical team members.

Short-Term Vs Long-Term Risk Strategies

Balance immediate needs with future protection:

Quick Response Tactics

- Emergency response plans

- Crisis communication

- Backup suppliers

- Safety stock levels

- Alternative transport

Building Long-Term Resilience with Supply Chain Risk Management

- Supplier relationship programs

- Technology investment

- Team development

- Process improvement

- Market diversification

Psychology of Supply Chain Risk

Understanding how people think about risk improves your decision-making:

Common Decision Traps

- Overconfidence bias

- Status quo preference

- Short-term thinking

- Group-think

- Confirmation bias

Better Decision-Making Tools

- Decision matrices

- Pre-mortem analysis

- Devil’s advocate sessions

- Scenario planning

- Peer review process

A good SCRM combines both systems and people. The best technology won’t help if your team isn’t ready to use it.

Taking Action

Let’s wrap up what we’ve covered and outline your next moves in strengthening your supply chain.

Key Takeaways You Can Use Today

The basics matter most:

- Know your risks

- Map your supply chain

- Build strong relationships

- Train your team

- Monitor constantly

Remember that semiconductor shortage in 2021? Companies with solid SCRM practices recovered faster and lost less money than their unprepared competitors.

Where to Start Tomorrow

Quick wins to tackle first:

- Map your top 5 suppliers

- List your biggest risks

- Check insurance coverage

- Update contact lists

- Review backup plans

Building for the Future

Focus areas for 2024 and beyond:

- AI and automation adoption

- Sustainability measures

- Supplier diversity

- Digital transformation

- Team development

Don’t try to fix everything at once. Pick one area, make it work, then move to the next.

Your Action Plan

This Week:

- Review current risks

- Talk to key suppliers

- Check emergency plans

- Update team contacts

- Schedule risk review

This Quarter:

- Start supplier assessments

- Update procedures

- Train key staff

- Test backup plans

- Review insurance

This Year:

- Implement monitoring tools

- Develop supplier network

- Build resilience plans

- Improve sustainability

- Measure progress

Final Thoughts

Supply chain risk management isn’t a one-time project – it’s how you do business.

Start small, keep improving, and remember: the best time to fix your supply chain is before it breaks.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs