Six Sigma Body of Knowledge: Guide for Process Excellence

A comprehensive guide covering all aspects of this impactful process enhancement technique is key to achievement.

Success relies on a strong grasp of essential ideas, tools, and strategies laid out in such a guide.

Without solid foundations in place, even the best of intentions around Six Sigma work could stumble, possibly yielding less than-ideal outcomes and resources not used as effectively as hoped.

A thorough training and certification framework anchored by a robust guide ensures comprehension of ins and outs.

Following an established guideline encompassing the full methodology ensures initiatives stay on track. It helps practitioners properly understand this approach’s innate complexities.

Only then can Six Sigma’s powerful problem-solving potential be fully unlocked to make meaningful improvements.

A well-rounded curriculum involving all pieces of the technique lays the necessary groundwork for fruitful implementation and returns.

The SSBOK is the backbone that underpins the entire Six Sigma philosophy, providing a structured framework for training, certification, and implementation of this powerful process improvement approach.

The success hinges on a thorough understanding of the core concepts, tools, and techniques outlined in a robust SSBOK.

Without this foundational knowledge, even the most well-intentioned Six Sigma initiatives can falter, leading to suboptimal results and wasted resources.

Key Highlights

- The Six Sigma Body of Knowledge is a comprehensive collection of topics, principles, and methodologies that define the minimum competencies required for each Six Sigma Belt level.

- A well-defined SSBOK ensures consistent training, adherence to professional standards, and a common language for Six Sigma practitioners across industries and organizations.

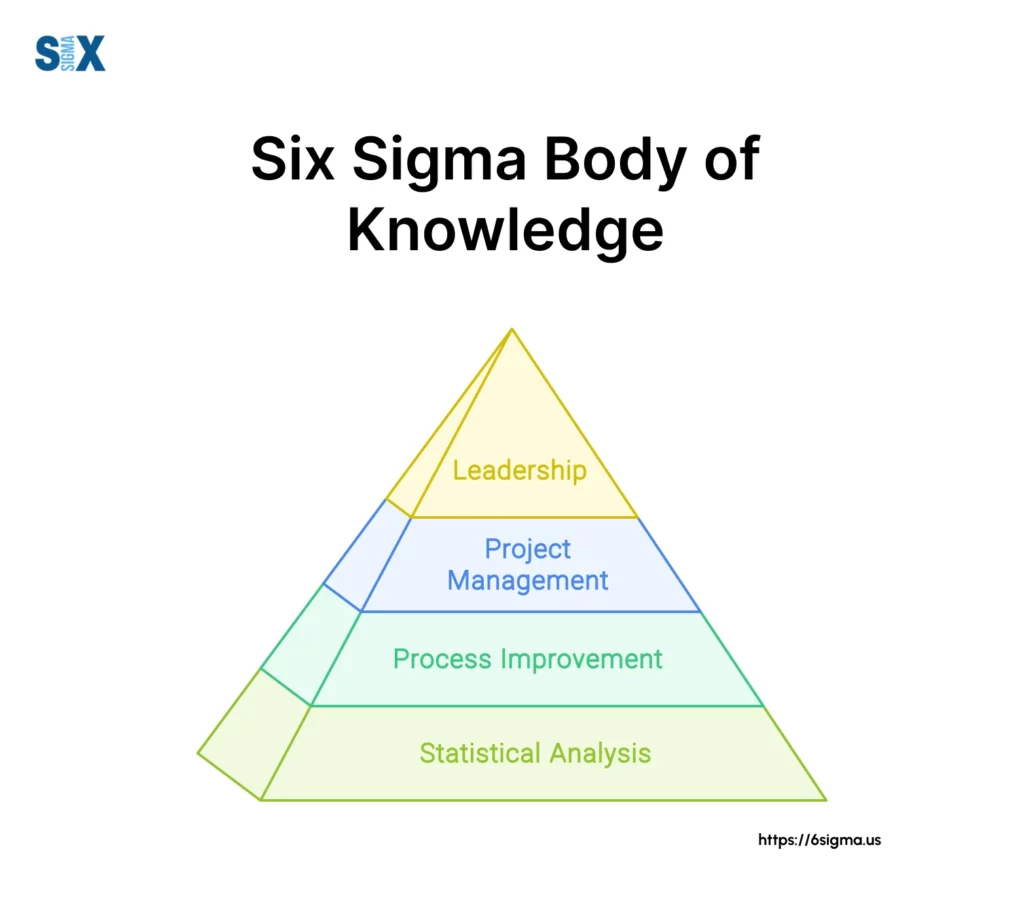

- The SSBOK covers a wide range of areas.

- While no single governing body dictates a universally accepted SSBOK, organizations like the American Society for Quality (ASQ) and the International Association for Six Sigma Certification (IASSC) provide widely recognized standards and guidelines.

- Mastering the Six Sigma Body of Knowledge is essential for practitioners to effectively apply Six Sigma tools and techniques.

- Addressing challenges such as data quality issues, resistance to change, and alignment with business goals is crucial for leveraging the full potential of the Six Sigma Body of Knowledge.

Introduction to Six Sigma Body of Knowledge

Six Sigma is a disciplined, data-driven approach to eliminating defects, waste, and undesirable variations in processes.

Six Sigma aims to achieve a level of excellence where a process operates at no more than 3.4 defects per million opportunities (DPMO).

This pursuit of near-perfection is driven by a profound understanding of customer requirements, a relentless focus on reducing variation, and a commitment to making decisions based on factual data analysis.

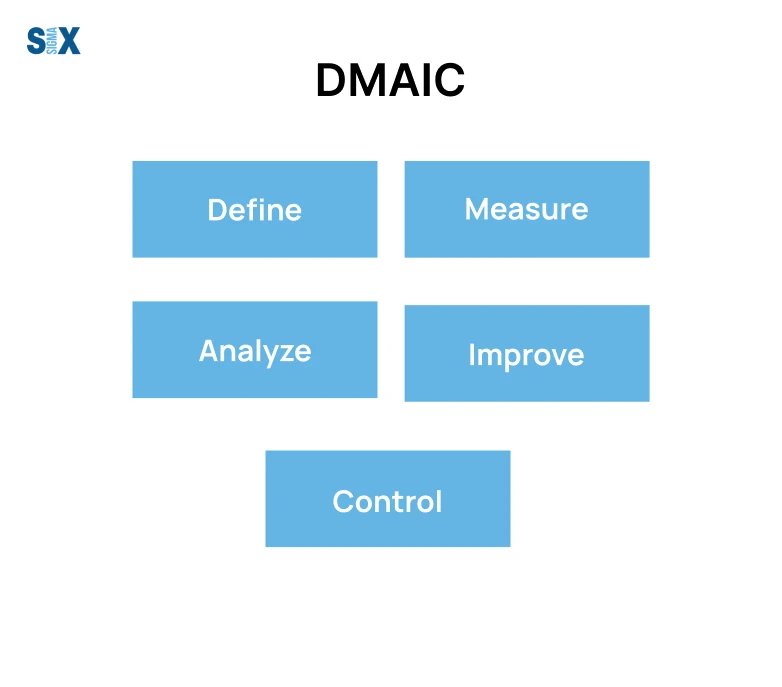

The Six Sigma methodology revolves around the DMAIC (Define, Measure, Analyze, Improve, Control) cycle, a structured problem-solving framework that guides practitioners through the entire process improvement journey.

Importance of Six Sigma Body of Knowledge

The Six Sigma Body of Knowledge (SSBOK) is the foundation upon which the entire Six Sigma philosophy rests.

It serves as a comprehensive repository of the concepts, principles, tools, and techniques that Six Sigma practitioners must master to drive meaningful process improvements within their organizations.

Without a well-defined SSBOK, Six Sigma initiatives run the risk of inconsistency, inefficiency, and suboptimal results. A robust SSBOK ensures:

- Consistent Training: By providing a standardized curriculum, the SSBOK enables organizations to deliver consistent and high-quality Six Sigma training across all Belt levels, from White Belts to Master Black Belts.

- Professional Standards: The SSBOK establishes a common language and set of expectations for Six Sigma professionals, ensuring that certified individuals possess the necessary knowledge and skills to tackle complex process improvement challenges effectively.

- Continuous Improvement: As a comprehensive knowledge base, the SSBOK serves as a foundation for ongoing learning and professional development, enabling practitioners to continuously enhance their Six Sigma capabilities and drive sustained organizational excellence.

Understanding Six Sigma Belts and Certifications: Six Sigma Body of Knowledge (SSBoK)

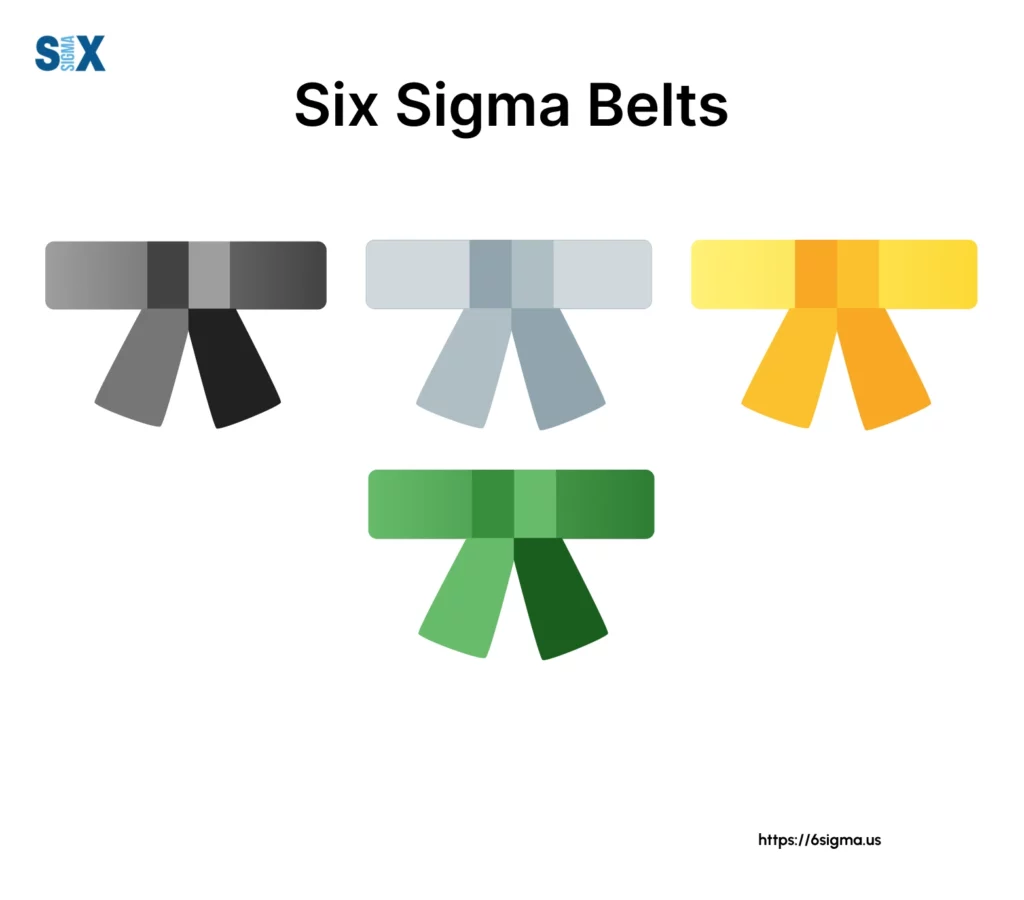

The Six Sigma Body of Knowledge encompasses a hierarchical structure of belt levels, each representing a distinct level of expertise and competency.

These belt levels are widely recognized across industries and serve as a benchmark for Six Sigma proficiency.

White Belt

White Belts possess a basic understanding of Six Sigma fundamentals and their application within an organization.

This introductory level is typically intended for individuals who may not be directly involved in Six Sigma projects but need to be aware of the key concepts and principles to support the organization’s continuous improvement efforts.

Yellow Belt

Yellow Belts have received basic training in Six Sigma methodology and participate in supporting roles within Six Sigma teams.

They possess a foundational knowledge of Six Sigma tools and techniques, enabling them to contribute to project execution and data-gathering efforts under the guidance of more experienced Belt holders.

Green Belt

Green Belts are Six Sigma practitioners who work closely with Black Belts, taking on significant responsibilities in data collection, analysis, and process improvement initiatives.

They have a comprehensive understanding of Six Sigma tools and methodologies, allowing them to lead small-scale projects or assist in larger, more complex endeavors.

Black Belt

Black Belts are the leaders and drivers of Six Sigma initiatives within an organization.

They possess advanced expertise in Six Sigma principles, statistical analysis, project management, and change management.

Black Belts are responsible for defining project scopes, leading cross-functional teams, and ensuring successful implementation of process improvements.

Master Black Belt

Master Black Belts represent the pinnacle of Six Sigma expertise.

They are highly experienced professionals who have demonstrated mastery in Six Sigma methodologies, statistical analysis, and process improvement strategies.

Master Black Belts often serve as mentors, coaches, and Subject Matter Experts (SMEs), guiding organizations in developing and deploying comprehensive Six Sigma programs.

Achieving certification at each Belt level requires a combination of training, hands-on project experience, and successful completion of rigorous examinations.

Core Concepts and Principles within Six Sigma Body of Knowledge (SSBoK)

The Six Sigma Body of Knowledge encompasses a robust set of core concepts and principles that form the foundation of the Six Sigma methodology.

These fundamental elements are essential for practitioners to understand and apply effectively, regardless of their Belt level or industry.

DMAIC Process (Define, Measure, Analyze, Improve, Control)

The DMAIC (Define, Measure, Analyze, Improve, Control) process is the cornerstone of the Six Sigma methodology.

- Define: In this phase, practitioners clearly define the problem, establish project goals, and identify key stakeholders and customer requirements.

- Measure: The Measure phase involves collecting baseline data and establishing metrics to accurately assess the current state of the process.

- Analyze: During the Analyze phase, practitioners employ various statistical tools and techniques to identify root causes of process variations and defects.

- Improve: In the Improve phase, solutions are developed, evaluated, and implemented to address the identified root causes and optimize the process.

- Control: The Control phase focuses on establishing monitoring mechanisms, control plans, and sustainment strategies to maintain the improvements and prevent process deviations over time.

Lean Principles and Waste Elimination

Six Sigma is closely aligned with lean principles, which emphasize the elimination of waste and non-value-added activities within processes.

The SSBOK incorporates lean concepts such as the identification and elimination of the seven types of waste (overproduction, waiting, transportation, over-processing, inventory, motion, and defects), as well as methodologies like 5S and value stream mapping.

Statistical Analysis and Data-Driven Decisions

At the heart of Six Sigma lies a strong emphasis on data-driven decision-making.

The SSBOK equips practitioners with a comprehensive understanding of statistical analysis techniques, including hypothesis testing, regression analysis, design of experiments (DOE), and process capability studies.

Process Mapping and Value Stream Mapping

Effective process improvement requires a deep understanding of the current state of processes.

The Six Sigma Body of Knowledge includes methodologies for process mapping and value stream mapping, which allow practitioners to visualize and analyze process flows, identify bottlenecks, and uncover opportunities for optimization.

Six Sigma Tools and Techniques & Six Sigma Body of Knowledge (SSBOK)

The Six Sigma Body of Knowledge encompasses a comprehensive set of tools and techniques that practitioners employ throughout the DMAIC process to identify, analyze, and address process inefficiencies and defects.

These tools and techniques are designed to facilitate data-driven decision-making, root cause analysis, and effective solution implementation.

Voice of the Customer (VOC)

The Voice of the Customer (VOC) is a crucial tool that ensures process improvements are aligned with customer needs and expectations.

By gathering and analyzing customer feedback, requirements, and preferences, Six Sigma practitioners can define Critical-to-Quality (CTQ) characteristics and prioritize improvement efforts accordingly.

Cause and Effect Diagrams (Fishbone Diagrams)

Cause and Effect Diagrams, also known as Fishbone Diagrams or Ishikawa Diagrams, are visual representations that help identify potential root causes of a problem or defect.

Failure Mode and Effects Analysis (FMEA)

Failure Mode and Effects Analysis (FMEA) is a proactive risk assessment tool used to identify potential failure modes in a process or product, evaluate their potential effects, and prioritize mitigation actions.

Control Charts and Process Capability

Control charts are statistical tools used to monitor and control process performance over time.

By analyzing control chart patterns, practitioners can distinguish between common cause variation (inherent to the process) and special cause variation (resulting from assignable causes), enabling targeted improvement efforts.

Hypothesis Testing and Sample Size Calculations

Six Sigma heavily relies on statistical hypothesis testing to make data-driven decisions and draw valid conclusions.

Practitioners use various hypothesis testing techniques, such as t-tests, ANOVA, and chi-square tests, to determine the significance of observed differences or relationships.

Sample size calculations are another critical aspect of Six Sigma, ensuring that data collection efforts are statistically valid and representative.

By determining appropriate sample sizes, practitioners can achieve the desired levels of confidence and precision in their analyses, minimizing the risk of erroneous conclusions.

Project Management and Team Dynamics within Six Sigma Body of Knowledge (SSBOK)

Successful Six Sigma initiatives require effective project management and strong team dynamics.

The Six Sigma Body of Knowledge provides a framework for managing projects, fostering collaboration, and driving organizational change.

Project Charters and Selection Criteria

The SSBOK emphasizes the importance of establishing clear selection criteria for prioritizing and selecting projects that align with organizational objectives and deliver measurable impact.

Team Roles and Responsibilities

Six Sigma projects involve cross-functional teams with clearly defined roles and responsibilities.

Effective team dynamics and role clarity are essential for project success.

Timelines, Scheduling, and Milestones

Proper planning and scheduling are critical components of Six Sigma project management. The SSBOK guides creating project timelines, setting milestones, and managing resources effectively.

Techniques like critical path analysis and phase-based timelines help practitioners keep projects on track and ensure timely completion.

Change Management and Training

Implementing process improvements often requires significant organizational change.

The Six Sigma Body of Knowledge emphasizes the importance of change management strategies, including stakeholder engagement, communication plans, and employee training.

Effective change management enables organizations to overcome resistance and foster a culture of continuous improvement.

Applications of Six Sigma Body of Knowledge (SSBOK)

The Six Sigma Body of Knowledge has found widespread application across a diverse range of industries and sectors, a testament to its versatility and effectiveness in driving process improvement and organizational excellence.

Manufacturing and Production

Six Sigma has its roots in the manufacturing and production sectors, where it has been instrumental in reducing defects, increasing productivity, and optimizing processes.

From automotive and aerospace to electronics and consumer goods, the SSBOK has enabled organizations to streamline operations, minimize waste, and enhance product quality.

Healthcare and Medical Processes

The healthcare industry has embraced Six Sigma principles to improve patient care, enhance operational efficiency, and reduce medical errors.

By applying the SSBOK, healthcare organizations can optimize clinical processes, streamline administrative procedures, and ensure consistent delivery of high-quality, patient-centered care.

Service Industries and Customer Experience

The service sector has leveraged the Six Sigma Body of Knowledge to enhance customer experience, improve service quality, and optimize operational processes.

Financial Services and Business Processes

Financial institutions and businesses across various sectors have adopted Six Sigma principles to improve operational efficiency, reduce costs, and mitigate risks.

By applying the SSBOK, organizations can optimize processes such as accounting, compliance, supply chain management, and human resources, driving increased productivity and profitability.

Continuous Improvement and Integration

The Six Sigma Body of Knowledge emphasizes the importance of continuous improvement and integration with other methodologies and organizational practices to sustain and amplify the impact of process improvements.

Sustaining Improvements and Control Plans

Achieving process improvements is just the first step; sustaining those improvements over time is equally crucial.

The SSBOK guides on developing robust control plans, establishing monitoring mechanisms, and fostering a culture of continuous improvement.

Integrating Six Sigma with Other Methodologies

While Six Sigma is a powerful methodology, it can be further enhanced by integrating it with other process improvement frameworks and principles.

The SSBOK encourages practitioners to explore synergies between Six Sigma and methodologies such as Lean, Theory of Constraints (TOC), and Agile, leveraging the strengths of each approach to drive comprehensive organizational excellence.

Organizational Culture and Leadership

Successful Six Sigma deployments require strong leadership commitment and a culture that embraces continuous improvement.

The SSBOK emphasizes the importance of cultivating a supportive organizational culture, fostering employee engagement, and aligning Six Sigma initiatives with strategic goals.

Six Sigma Body of Knowledge Standards

While there is no single globally recognized governing body that dictates a definitive Six Sigma Body of Knowledge, several reputable organizations have established widely accepted standards and guidelines.

American Society for Quality (ASQ)

The American Society for Quality (ASQ) is a leading authority in the field of quality management and process improvement.

ASQ’s Six Sigma Body of Knowledge serves as a widely recognized benchmark for Six Sigma training and certification programs.

International Association for Six Sigma Certification (IASSC)

The International Association for Six Sigma Certification (IASSC) is another respected organization that has developed a comprehensive Six Sigma Body of Knowledge.

IASSC’s standards are widely recognized and utilized by Six Sigma training providers, institutions, and practitioners worldwide.

IASSC’s certifications are based on their Lean Six Sigma Body of Knowledge, ensuring a consistent level of competency and proficiency among certified individuals.

Industry-Specific Standards and Customizations

While organizations like ASQ and IASSC provide general Six Sigma standards, some industries have developed customized versions of the Six Sigma Body of Knowledge to address industry-specific challenges and requirements.

These industry-specific standards often build upon the foundational principles of Six Sigma while incorporating industry-specific tools, techniques, and best practices.

Challenges and Best Practices within Six Sigma Body of Knowledge (SSBOK)

While the Six Sigma Body of Knowledge provides a robust framework for process improvement, organizations may encounter various challenges during implementation.

Data Collection and Quality Issues

Reliable data is the foundation of Six Sigma, and data collection and quality issues can significantly impact the effectiveness of process improvement efforts.

Organizations must establish robust data collection procedures, implement data governance policies, and ensure the use of appropriate measurement systems to mitigate data quality concerns.

Resistance to Change and Employee Engagement

Implementing Six Sigma often requires significant organizational and cultural changes, which can lead to resistance from employees.

Effective change management strategies, open communication, and employee engagement are crucial for overcoming this challenge.

Alignment with Business Goals and Metrics

Six Sigma initiatives must be aligned with the organization’s strategic goals and metrics to ensure their relevance and impact.

Organizations should establish a clear link between process improvements and business objectives, such as cost reduction, revenue growth, or customer satisfaction.

Regular monitoring and reporting of key performance indicators (KPIs) can help maintain this alignment.

Continuous Learning and Professional Development with Six Sigma Body of Knowledge (SSBOK)

The Six Sigma Body of Knowledge is constantly evolving, and practitioners must embrace continuous learning and professional development to stay current with best practices and emerging trends.

Organizations should encourage and support ongoing training, certifications, and knowledge sharing to foster a culture of continuous improvement and maintain a competitive edge.

Conclusion

The Six Sigma Body of Knowledge represents a thorough framework for advancing process enhancement and organizational excellence.

Mastering core ideas, tools, and methods laid out ensures effective navigation of complex optimization, informed decision-making, and tangible results aligned with customer and business aims.

However, it is important to see the SSBOK as adaptable, not fixed. It evolves to suit organizational and industrial changes.

An outlook of continuous self-improvement is key for Six Sigma practitioners to stay ahead by capitalizing on the latest methodology advances.

The SSBOK remains a beacon, guiding harmony between efficient operations, satisfied customers, and sustainable growth.

Combining its insights with complementary techniques opens Six Sigma’s full potential for transformation.

This comprehensive exploration has provided valuable lessons and a deeper appreciation for the methodology’s power.

Applying the principles, tools, and strategies described can start a journey where quality becomes standard and customer focus drives every enhancement effort.

Continuous betterment becomes the norm, driving new heights of operational excellence.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs