Screening DOE: Efficient Factorial Designs for Identifying Key Variables

Among the most impactful techniques in the Six Sigma arsenal lies the Design of Experiments (DOE). Within this vital area, screening DOE assumes a critical purpose by pinpointing pertinent metrics efficiently.

Whether experienced practitioner or newcomer to DOE’s realm, comprehending screening designs proves integral for streamlining your experimentation design process.

It empowers informed choices distinguishing genuinely influential metrics.

So whether manufacturing, services, or elsewhere, consider leveraging its capacity to isolate key factors purposefully. Illumination of significant variables readies subsequent investigations for fruitful optimization — driving elevated results within your domain.

Key Highlights

- Overview of screening Design of Experiments (DOEs) and their purpose in identifying significant process variables

- Comparison of screening DOEs with full factorial DOEs, highlighting their differences in terms of main effects, interactions, and resolution

- Detailed discussion of the benefits and drawbacks of screening DOEs

- Explanation of when to use this, such as when dealing with a large number of process variables or preparing for optimizing DOEs

- Introduction to various types of screening designs, including 2-level fractional factorial designs, Plackett-Burman designs, and definitive screening designs

- Best practices for conducting successful screening DOEs, including eliminating noise and contamination, understanding objectives, and assessing interaction importance

- Insights into interpreting resolution, choosing the appropriate design type, and revisiting and refining screening DOEs through techniques like folding and axial runs

What is a Screening DOE?

Screening DOE is an invaluable tool in the Six Sigma arsenal.

They allow us to efficiently identify the most critical factors influencing a process or product, saving time and resources while still providing valuable insights.

However, it’s important to understand what it is and how it differs from other experimental designs.

Overview of Screening DOE

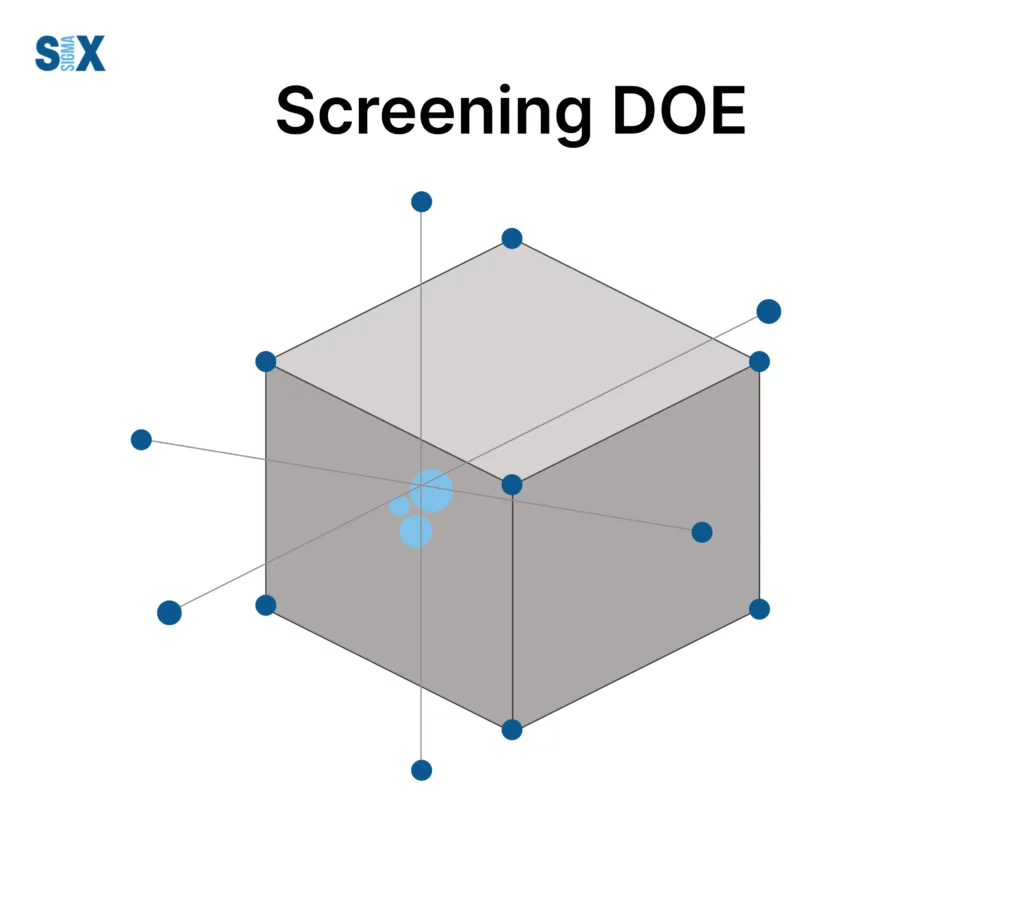

A screening DOE, also known as a fractional factorial DOE, is a type of experimental design that allows us to investigate the main effects of multiple factors on a response variable.

Unlike a full factorial DOE, which tests every possible combination of factor levels, this uses a carefully selected subset of runs to screen out insignificant factors.

Two common screening DOE techniques are fractional factorial designs and Plackett-Burman designs.

Purpose of Screening DOE

The primary purpose of a screening DOE is to reduce the number of experimental runs required by identifying the most influential factors early on.

This is particularly useful when dealing with processes or products that involve a large number of potential factors, as running a full factorial DOE would be impractical and resource-intensive.

By screening out insignificant factors, we can focus our efforts on the remaining critical factors, saving time and costs.

Screening DOE vs. Full Factorial DOE

While a full factorial DOE provides a comprehensive understanding of the main effects and interactions between factors, a screening DOE sacrifices some resolution by confounding interactions with main effects.

This trade-off is often acceptable, as the primary goal of this is to identify the most significant main effects quickly and efficiently.

However, it’s crucial to understand that screening DOEs may not capture all interactions, so follow-up experiments or a full factorial DOE may be necessary if interactions are deemed important.

Benefits and Drawbacks of Screening DOE

Like any experimental design technique, screening DOE comes with its own set of advantages and limitations.

It’s essential to weigh these factors carefully to determine if this is the right approach for your specific situation.

Cost and Time Savings

One of the primary benefits of screening DOEs is the significant cost and time savings they offer.

By reducing the number of experimental runs required, screening DOE minimizes the amount of scrap or discarded product, as well as the time and resources needed to experiment.

This efficiency can be particularly valuable in industries where product development or manufacturing costs are high.

Reduced Effort and Information

Screening DOEs are designed to be more efficient than full factorial DOEs, requiring less effort to execute while still providing valuable information about the main effects of factors.

However, it’s important to note that this efficiency comes at the cost of reduced information about interactions between factors, which may or may not be relevant depending on the specific experimental goals.

Limitations

While screening DOE offers many advantages, they also have limitations.

As mentioned earlier, they sacrifice resolution by confounding interactions with main effects, potentially missing important information about how factors interact.

Additionally, this may not be able to detect quadratic or higher-order effects, which can be important in some processes or products.

When to Use a Screening DOE

While the decision ultimately depends on the specific goals and constraints of the experiment, there are several common scenarios where screening DOE can be particularly useful.

A large Number of Process Variables

One of the primary situations where screening Design of Experiements shines is when you’re dealing with a process or product that involves a large number of potential factors or variables.

In these cases, running a full factorial DOE would require an impractical number of experimental runs, making a screening DOE a more efficient and cost-effective approach.

Identify the Most Significant Variables

If your goal is to quickly identify the most significant factors affecting a response variable, a screening DOE can be an excellent choice.

By screening out insignificant factors early on, you can focus your efforts and resources on the remaining critical factors, streamlining the experimental process.

Preparation for Optimization DOE

Screening DOE is often used as a precursor to optimization DOEs, where the goal is to find the optimal combination of factor levels for a desired response.

By first screening out insignificant factors with a screening Design of Experiments, you can reduce the complexity of the subsequent optimization DOE, making it more manageable and efficient.

Types of Screening Designs

While the concept of screening DOEs is fairly straightforward, there are several different types of screening designs available, each with its own strengths and limitations.

It’s important to understand the differences between these designs to choose the most appropriate one for your specific experimental needs.

2-Level Fractional Factorial Designs

Fractional factorial designs are one of the most common types of screening DOE.

These designs use a carefully selected subset of runs from a full factorial design, allowing you to estimate main effects while sacrificing some resolution and confounding interactions with main effects. 2-level fractional factorial designs are particularly useful when factors can be set at two levels (e.g., high and low).

Plackett-Burman Designs

Plackett-Burman designs are another popular type of screening DOE, particularly when dealing with a large number of factors.

These designs are based on the assumption that interactions are negligible, allowing you to estimate main effects using a relatively small number of runs.

However, this assumption may not always hold, and Plackett-Burman designs may not be suitable if interactions are suspected to be important.

Definitive Screening Designs

Definitive screening designs are a more recent development in the field of DOE, offering several advantages over traditional screening designs.

These designs allow you to estimate not only main effects but also quadratic effects and two-way interactions, providing a more comprehensive understanding of the process or product.

Definitive screening designs can be particularly useful when you suspect that interactions or quadratic effects may be significant.

Conducting a Successful Screening DOE

While screening DOE offers many benefits, its success ultimately depends on how they are designed and executed.

Eliminate Noise and Contamination

One of the most critical aspects of any DOE, including screening DOE, is minimizing the impact of extraneous variables or “noise” that can contaminate the results.

This can be achieved through careful experimental design, controlling for known sources of variation, and implementing robust measurement systems.

Failure to eliminate noise can lead to misleading results and incorrect conclusions about the significance of factors.

Understand the Purpose and Objectives

Before embarking on a screening DOE, it’s crucial to clearly define the purpose and objectives of the experiment.

Are you primarily interested in identifying the main effects, or do you suspect that interactions may play a significant role?

Understanding your goals will help you choose the appropriate screening design and avoid wasting resources on unnecessary runs or information.

Assess Interaction Importance

While screening DOE is designed to focus on the main effects, it’s important to consider the potential importance of interactions between factors.

Depending on the process or product under investigation, interactions may play a significant role in determining the response variable.

If interactions are deemed important, you may need to consider alternative screening designs or follow-up experiments to capture this information adequately.

Best Practices

Best practices to help you navigate the intricacies of this powerful experimental design technique.

Interpreting Resolution

One of the most common questions I receive is related to the concept of resolution in screening DOE.

Resolution refers to the degree of confounding between main effects and interactions, with lower-resolution designs sacrificing information about interactions.

Understanding resolution is crucial for interpreting the results of a screening DOE and determining if follow-up experiments are necessary to investigate potential interactions.

Choosing Design Type

Another frequent question concerns the selection of the appropriate screening design type. As discussed earlier, there are several options available, including fractional factorial designs, Plackett-Burman designs, and definitive screening designs. The choice of design depends on factors such as the number of factors being investigated, the importance of interactions, and the ability to incorporate sequential experimentation techniques like folding or adding axial runs.

Revisiting and Refining Screening DOE

Screening DOE is often just the first step in a larger experimental process.

Depending on the results and insights gained, it may be necessary to revisit and refine the screening DOE or transition to a different experimental design.

Techniques like folding or adding axial runs can be used to increase the resolution of a screening DOE and investigate interactions or quadratic effects, while a full factorial DOE may be warranted if interactions are found to be significant.

Conclusion

Screening DOE proves a potent instrument, effectively pinpointing influential factors through minimal expenditure and effort. Isolating insignificant metrics early streamlines subsequent experimentation.

This fosters enhanced comprehension and optimization targeting pivotal variables.

While screening DOE kicks off a broader experimental design, its importance cannot be understated.

By establishing solid foundations and uncovering the most promising areas warranting focus, screening primes investigations for achievement and improved outputs.

Embrace screening DOE’s power, yet with a clear understanding of its strengths, limits, and suitable applications.

Carefully weigh specific goals and practical constraints, judiciously select matching designs, and follow ideal methods ensuring reliable, usable insights.

Leveraging screening DOE’s efficiency and wisdom unlocks higher process refinement and product customization degrees, driving organizational accomplishments.

Its gifts in illuminating influential elements through abbreviated yet productive trials deserve recognition and applying wherever circumstances make a good fit.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs