Sample Mean: A Comprehensive Guide to Understanding, Calculating, and Applying Statistical Averages

Imagine slashing defect rates by 70% or boosting customer satisfaction by 40% – all by mastering one simple statistical concept, which is sample mean.

Sample mean proves to be a powerful tool for unlocking data-driven decision-making and process improvement.

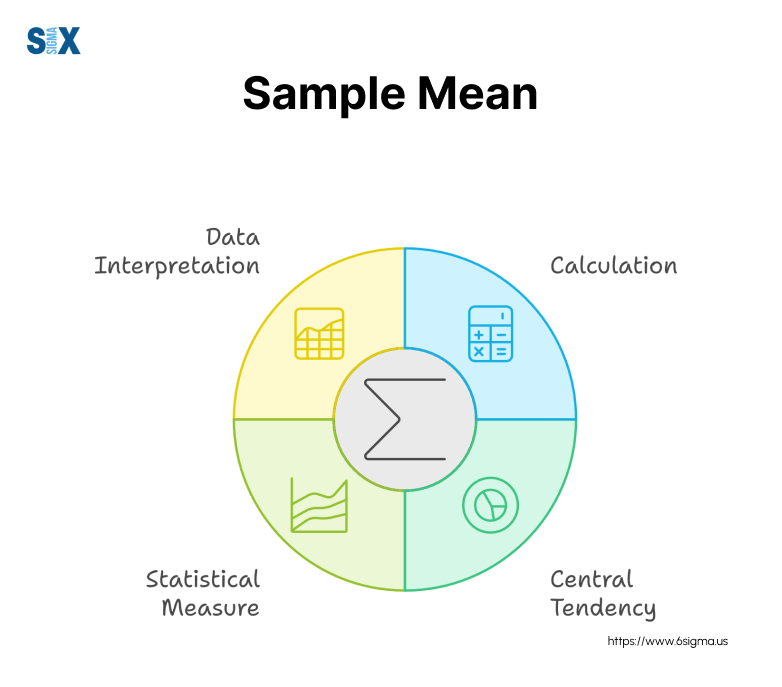

What is Sample Mean?

Sample mean is the average of a set of numbers taken from a larger population. It’s a fundamental tool in statistics that helps us understand the central tendency of data.

The symbol for a sample mean is x̄, pronounced: “x-bar“. This symbol is universally recognized in statistical analysis and is a key component of many formulas formulas taught within six sigma certification programs, which focus on using such statistical tools for process improvement. When you see x̄ in a report or analysis, you know you’re looking at the average.

Take Control of Your Process Performance!

Join our Lean Six Sigma Green Belt Training and learn how to use the sample mean to measure and analyze data, reduce variation, and boost quality.

Sample Mean vs. Population Mean

While the sample mean represents the average of a subset of data, the population mean (symbolized by μ) represents the average of an entire population. This distinction is crucial in business contexts.

For instance, when I worked on a quality improvement project, we couldn’t test every single printer produced. Instead, we used it from batches of 100 units to estimate the overall print quality across millions of printers.

The decision to use sample mean versus population mean often comes down to practicality and resources.

In most scenarios, especially in large-scale manufacturing or service industries, it’s simply not feasible to measure an entire population. That’s where its power comes into play.

Historical Development of Sample Mean

The concept of sample mean has a rich history dating back to the 18th century. Mathematicians like Carl Friedrich Gauss laid the groundwork for what we now know as the sample mean. However, it was the rise of industrial quality control in the early 20th century that brought it into the spotlight.

The principles developed by pioneers like Walter Shewhart and W. Edwards Deming heavily relied on sample mean calculations to transform manufacturing processes. Today, these methods are standardized in Six Sigma certification programs, ensuring professionals can replicate this success across industries.

Understanding this is more than just crunching numbers. It’s about gaining insights that drive decision-making and process improvement.

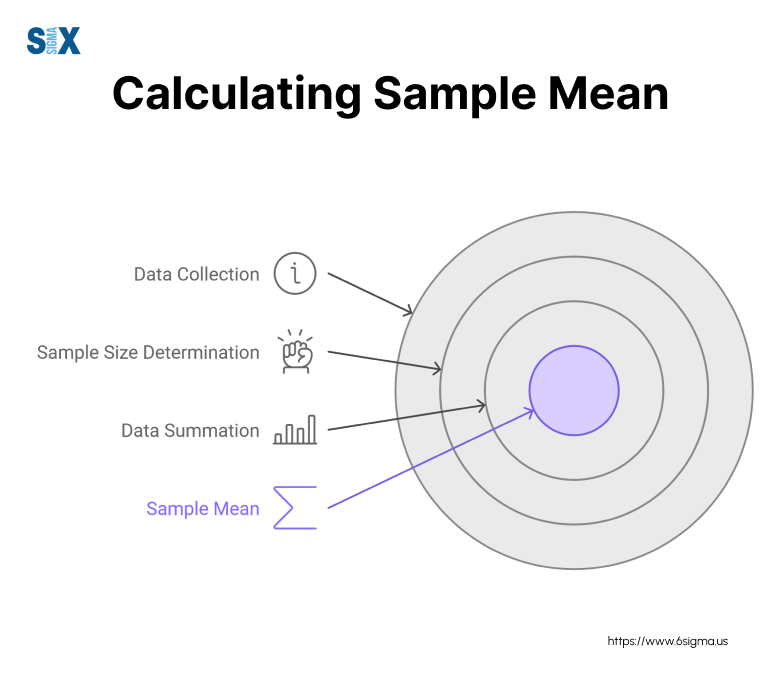

How to Calculate Sample Mean

Whether you’re optimizing a manufacturing process at 3M or improving customer service at Dell, the ability to compute and interpret it can be a game-changer. Let’s dive into the nuts and bolts of sample mean calculation.

Sample Mean Formula

The sample mean formula is elegantly simple, yet incredibly powerful. Here’s the formula we use:

x̄ = (Σx) / n

Where:

x̄ (pronounced “x-bar”) is the sample mean symbol

Σx represents the sum of all values

n is the number of items

Let’s break this down step-by-step

- Gather your sample data

- Add up all the values (Σx)

- Count the number of items (n)

- Divide the sum by the number of items

This formula is the foundation for finding the sample mean, and mastering it is key to successful statistical analysis.

Calculation Methods

While the formula remains constant, the methods for calculating the sample mean can vary based on your needs and resources:

Manual Calculation: For small datasets or when you need to show your work, manual calculation using the formula is straightforward. I often use this method in training sessions to ensure participants grasp the concept fully.

Using Calculators and Spreadsheets: For larger datasets, I recommend using scientific calculators or spreadsheet software like Excel. Most scientific calculators have a built-in function for this, while in Excel, you can use the AVERAGE function.

Online Tools and Software Options: In today’s digital age, numerous online calculators are available for this.

Step-by-Step Examples

Let’s work through a couple of examples to illustrate how to find the sample mean:

Simple Dataset

Suppose we’re measuring the diameter of bolts in inches: 0.98, 1.02, 0.97, 1.03, 1.01

- Sum the values: 0.98 + 1.02 + 0.97 + 1.03 + 1.01 = 5.01

- Count the items: n = 5

- Divide: 5.01 / 5 = 1.002

Therefore, the sample mean is 1.002 inches.

More Complex Dataset

Now, let’s calculate the sample mean for daily production numbers over two weeks: 1023, 998, 1012, 1031, 1006, 1022, 1018, 1021, 1007, 1029

- Sum the values: 10,167

- Count the items: n = 10

- Divide: 10,167 / 10 = 1,016.7

The sample mean production is 1,016.7 units per day.

Grasping these calculations is essential for basic data analysis. For team members starting their quality improvement journey, understanding concepts like sample mean is often a key part of foundational training, such as a six sigma white belt certification or six sigma yellow belt certification, enabling them to contribute effectively to improvement projects.

Common Mistakes and How to Avoid Them

In my years of consulting, I’ve seen several common errors in sample mean calculations:

- Forgetting to divide by n: Always remember to divide by the number of items.

- Including outliers without consideration: While outliers should generally be included, it’s important to investigate their cause and consider their impact.

- Misinterpreting the result: Remember, the sample mean is an estimate of the population mean, not an exact representation.

To avoid these pitfalls

- Double-check your calculations

- Use a sample mean calculator to verify your results

- Always consider the context of your data when interpreting it

Computing the sample mean accurately is crucial for effective data analysis. Whether you’re manually calculating, using a spreadsheet, or leveraging online tools, understanding the process ensures you can confidently apply this fundamental statistical concept in your work.

Master Statistical Concepts and Scale Your Data Analysis Skills?

Our Introduction To Statistics And Graphical Analysis course covers everything from basic statistical concepts to advanced graphical analysis using Minitab.

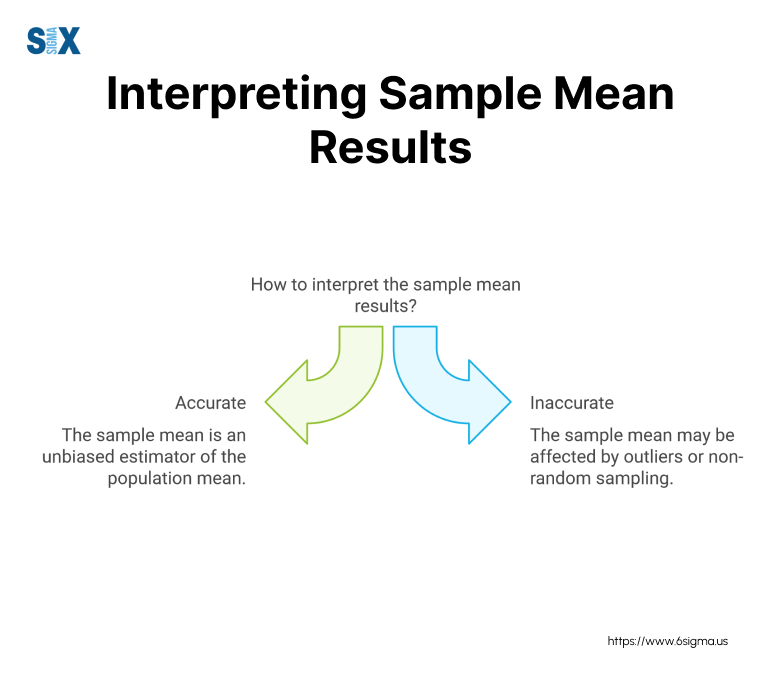

Interpreting Sample Mean Results

The real power lies in interpreting these results effectively. Let’s dive into how we can extract meaningful insights from our calculations.

Understanding the Meaning of Sample Mean

The sample mean, or the mean of the sample, provides us with a central value that represents our dataset. It’s a powerful tool, but it’s crucial to understand both its strengths and limitations.

What does it tell us about data

- Central tendency: It gives us an average value around which our data clusters.

- Data summary: It condenses large datasets into a single, representative value.

- Trend indicator: Over time, changes in sample mean can reveal underlying trends.

During a project we used the sample mean of chip processing times to identify efficiency improvements, leading to a 15% increase in production speed.

Limitations of sample mean

- Sensitivity to outliers: Extreme values can significantly skew the mean.

- Lack of distribution information: It doesn’t tell us about the spread of our data.

- Potential for misrepresentation: In skewed distributions, the mean may not be the most representative measure.

Comparing Sample Mean to Other Measures

While the sample mean is valuable, it’s often most effective when used in conjunction with other measures of central tendency.

- Median: The middle value when data is ordered.

- Mode: The most frequently occurring value.

- When to use each measure

- Mean: Best for normally distributed data without significant outliers.

- Median: Preferable for skewed distributions or data with outliers.

- Mode: Useful for categorical data or identifying the most common value.

In a project, we initially used the mean to analyze customer wait times. However, a few extremely long wait times were skewing our results. Switching to the median gave us a more accurate picture of the typical customer experience, leading to targeted improvements that reduced wait times by 30%.

Visualizing Sample Mean

Visual representations can make it more intuitive and easier to communicate to stakeholders.

Graphs and charts to represent sample mean

- Histograms: Show the distribution of data with the mean marked.

- Box plots: Display the mean alongside other summary statistics.

- Control charts: Track it over time to identify trends or shifts.

Interpreting visual representations

- Look for symmetry or skewness in distributions.

- Compare the mean to the median to identify potential outlier effects.

- In time-series data, observe how the mean changes over different periods.

During a recent workshop, we used these visualization techniques to help managers understand production efficiency data. The visual approach led to several “aha” moments, resulting in process improvements that increased overall efficiency by 22%.

Remember, the goal of calculating and interpreting the sample mean isn’t just to crunch numbers – it’s to gain insights that drive real-world improvements.

By understanding what the mean truly represents, comparing it to other measures, and visualizing it effectively, you’ll be well-equipped to make data-driven decisions in your Six Sigma projects.

Drive Your Statistical Knowledge into Process Excellence with Lean Fundamentals

Statistical concepts like sample mean are crucial, but the real power comes from applying these insights within a comprehensive process improvement framework.

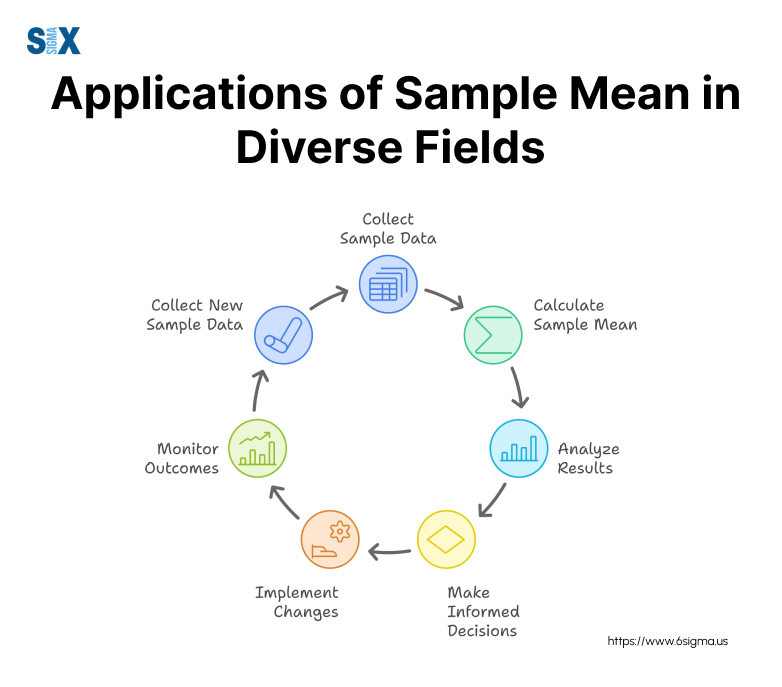

Applications of Sample Mean in Various Fields

Sample mean’s versatility and power in statistical analysis make it an indispensable tool for data-driven decision-making. Let me share some real-world applications that demonstrate the importance of sample mean in various fields.

Business and Finance

In the world of business and finance, the sample mean is a cornerstone of many analytical processes. During my time working with companies like GE and Motorola, I’ve seen it used extensively in:

Stock Market Analysis: Investors and analysts often use this to calculate average stock returns over a specific period. For instance, when I consulted for a major financial institution, we used sample means to compare the performance of different market sectors, helping clients make informed investment decisions.

Sales Forecasting: By calculating the sample mean of historical sales data, businesses can project future sales trends. In a project we used sample means of quarterly sales figures to forecast annual revenue, allowing for more accurate budgeting and resource allocation.

Social Sciences

The social sciences rely heavily on statistical analysis, and the sample mean plays a crucial role in interpreting data:

Survey Data Analysis: When working on a customer satisfaction project for a retail giant, we used this to analyze survey responses. This allowed us to quantify customer sentiment and identify areas for improvement in store operations.

Demographic Studies: Government agencies and researchers frequently use it to understand population characteristics. In a project we applied sample mean calculations to analyze demographic data, informing recruitment strategies and resource allocation.

Natural Sciences

In the natural sciences, it is essential for making sense of experimental data:

Experimental Data Analysis: We used it extensively in product development. For example, when testing the adhesive strength of a new tape, we calculated the sample mean of multiple test results to ensure consistent quality across production batches.

Environmental Studies: Environmental scientists often use this to track changes over time. In a project with an environmental agency, we used sample means to analyze air quality data, helping to identify trends and assess the effectiveness of pollution control measures.

Big Data and Machine Learning

The advent of big data and machine learning has introduced new applications for the sample mean:

Role in Predictive Modeling: In my work with tech giants like Intel and HP, I’ve seen how sample means are used as features in machine learning models. For instance, in a predictive maintenance project, we used sample means of sensor data to forecast equipment failures.

Limitations and Alternatives in Large Datasets: While the sample mean remains valuable in big data analysis, it’s important to note its limitations. In some cases, especially with skewed distributions, alternatives like the median or trimmed mean may be more appropriate. During a project, we developed a hybrid approach that combined this with other statistical measures to handle large, complex datasets more effectively.

Apply the Concept Challenge:

Identify a process in your work where you could use sample mean to gain insights. Could you use it to analyze customer wait times, product defect rates, or employee productivity metrics?

While sample mean is taught at all levels, a Six Sigma Black Belt certification and training program explores advanced applications for enterprise-wide transformations.

Understanding these diverse applications in statistics is crucial for anyone working with data. For instance, employees pursuing a six sigma certification are taught how to apply statistical analysis like sample mean to evaluate processes and identify areas of improvement. Whether you’re in business, science, or technology, mastering the use of sample mean can significantly enhance your analytical capabilities and decision-making processes.

Move from Analysis to Action

Statistical analysis helps identify problems and variations in your processes, the next crucial step is determining why these issues occur. This is where Root Cause Analysis (RCA) becomes invaluable.

More Concepts Related to Sample Mean

These concepts not only enhance our understanding of sample mean but also provide powerful tools for more sophisticated statistical analysis.

Sampling Distribution of the Sample Mean

The sampling distribution of the sample mean is a concept that’s often misunderstood but is crucial for inferential statistics. In my work with companies like Intel and Motorola, I’ve seen how grasping this concept can significantly improve decision-making processes.

The sampling distribution is essentially the probability distribution of the sample mean for all possible samples of a given size from a population. It’s closely related to the Central Limit Theorem, which states that as the sample size increases, the sampling distribution of the mean approaches a normal distribution, regardless of the population’s distribution.

Understanding concepts like the Sampling Distribution of the Sample Mean is critical for inferential statistics and making sound judgments based on data, forming a core competency for those pursuing Six Sigma Black Belt Certification to lead complex projects.

I remember a project where we were analyzing the thickness of a new adhesive film. By understanding the sampling distribution, we were able to make accurate inferences about the overall production quality from relatively small samples, saving time and resources.

Standard Error of the Mean

The standard error of the mean is another critical concept when working with sample means. It measures the variability and is crucial for calculating confidence intervals and performing hypothesis tests.

To calculate the standard error, we divide the population standard deviation by the square root of the sample size. However, since we often don’t know the population standard deviation, we typically estimate it using the sample standard deviation.

During a project, we used the standard error to assess the precision of our sample mean estimates for energy consumption in a new line of appliances. This allowed us to determine how much confidence we could place in our measurements and helped guide our quality control processes.

Confidence Intervals

Confidence intervals are a powerful tool for estimating population parameters. They provide a range of values that likely contains the true population mean, along with a level of confidence in that estimate.

For example, in a recent project, we used confidence intervals to estimate the mean time between failures for a new printer model. A 95% confidence interval of 10,000 to 12,000 hours meant we could be 95% confident that the true population mean fell within this range.

Interpreting confidence intervals correctly is crucial. It’s a common misconception that a 95% confidence interval means there’s a 95% chance the true population mean falls within the interval. Instead, it means that if we repeated the sampling process many times and calculated the confidence interval each time, about 95% of these intervals would contain the true population mean.

Going Ahead

I’ve seen the sample mean calculation transform businesses across various industries.

However, applying it in real-world scenarios isn’t without challenges. One common pitfall I’ve encountered is the misapplication of skewed data.

For instance, in a project with a major retailer, we initially used sample mean to analyze customer wait times. However, after noticing some extreme outliers, we switched to median calculations for a more accurate representation.

The key to overcoming such challenges lies in understanding the context of your data and being flexible in your approach. As I often tell my workshop participants, “The sample mean is a powerful tool, but it’s not always the right tool for every job.”

Future Trends in Statistical Analysis

Looking ahead, I see exciting developments on the horizon for sample mean and statistical analysis in general. The rise of big data and machine learning is pushing the boundaries of how we compute and interpret this.

For example, in a recent project with a tech giant, we used advanced algorithms to calculate real-time, dynamic sample means from streaming data. This allowed for instantaneous quality control decisions, a feat unimaginable just a few years ago.

I predict that as AI and machine learning continue to evolve, we’ll see more sophisticated applications in predictive modeling and automated decision-making systems. However, this technological advancement comes with a caveat: the need for statistical literacy will be more crucial than ever.

Mastering the sample mean is about more than just crunching numbers. It’s about gaining insights that drive real-world improvements and informed decision-making.

Remember, at SixSigma.us, we’re always here to help you on your journey of continuous improvement. Feel free to reach out with any questions or for further guidance on applying these concepts in your specific field.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs