Understanding Non-Parametric Tests in Six Sigma

Statistical analysis forms the backbone of data-driven decision-making in Six Sigma methodology.

Non-parametric tests serve as essential tools when dealing with data that doesn’t follow normal distribution patterns or when working with ordinal and nominal measurements.

These statistical methods help Six Sigma practitioners analyze process data without making assumptions about the underlying population distribution.

By using rank-based approaches and distribution-free techniques, non-parametric tests provide reliable insights even when traditional parametric methods might not be suitable.

Key Highlights

- Test selection and implementation strategies

- Data analysis techniques for process improvement

- Real-world applications in manufacturing

- Statistical software tools and methods

What Are Non-Parametric Tests?

Non-parametric tests are statistical methods that analyze data without assuming it follows a specific probability distribution.

These tests work effectively with data that doesn’t meet the normal distribution requirements typically needed for traditional parametric testing.

Basic Principles of Non-Parametric Testing

Unlike parametric methods that rely on population parameters like mean and standard deviation, non-parametric tests focus on data rankings and orders.

They evaluate median values rather than means, making them suitable for analyzing ordinal data and situations where outliers might skew results.

Role of Non Parametric Tests in Six Sigma Projects

Six Sigma practitioners often encounter data that doesn’t fit normal distribution patterns.

Non-parametric tests provide reliable analysis methods during the DMAIC process, particularly in the Analyze phase.

These tests help teams:

- Compare process performances before and after improvements

- Evaluate customer satisfaction ratings

- Analyze defect counts and rankings

- Assess qualitative feedback from process stakeholders

The flexibility of non-parametric tests makes them valuable tools for quality improvement projects where data might not meet traditional statistical assumptions.

Key Applications of Non Parametric Tests in Process Improvement

Quality engineers and process improvement teams use non-parametric tests to analyze various data types.

Common applications include comparing multiple process conditions, evaluating supplier performance, and measuring customer satisfaction levels.

For example, when analyzing customer feedback ratings on a 1-5 scale, traditional parametric tests might not be appropriate.

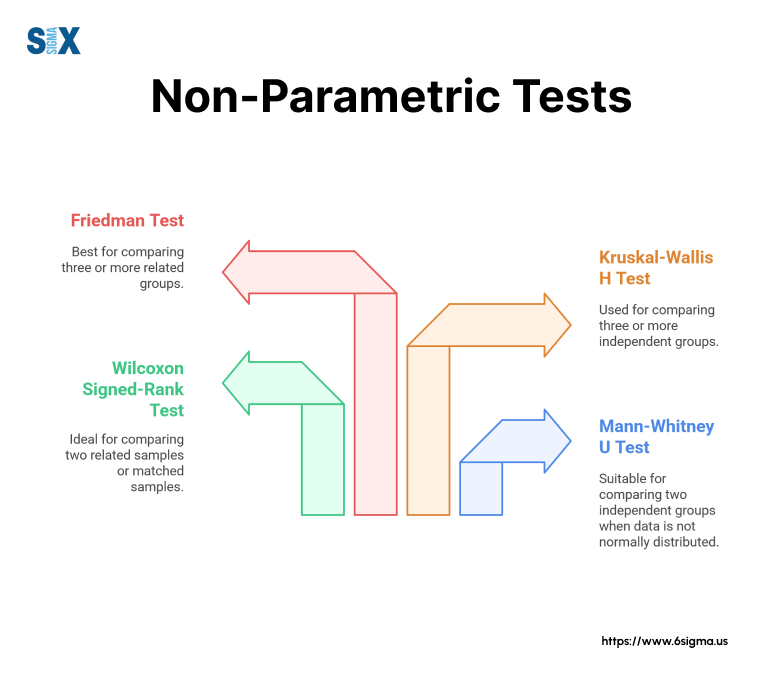

Non-parametric methods like the Mann-Whitney test or Kruskal-Wallis test provide more reliable results for such ordinal data.

Statistical Validity and Reliability

While non-parametric tests might have slightly less statistical power than their parametric counterparts when analyzing normally distributed data, they often provide more reliable results when working with:

- Skewed distributions

- Ordinal measurements

- Small sample sizes

- Data with significant outliers

Understanding these characteristics helps Six Sigma teams choose the most appropriate statistical methods for their specific process improvement needs.

Parametric vs Non-Parametric Tests: Making the Right Choice

Statistical testing methods fall into two main categories: parametric and non-parametric tests. Each approach serves specific purposes in data analysis and process improvement projects.

Understanding their differences helps in selecting the most suitable method for your data analysis needs.

Key Differences in Testing Approaches

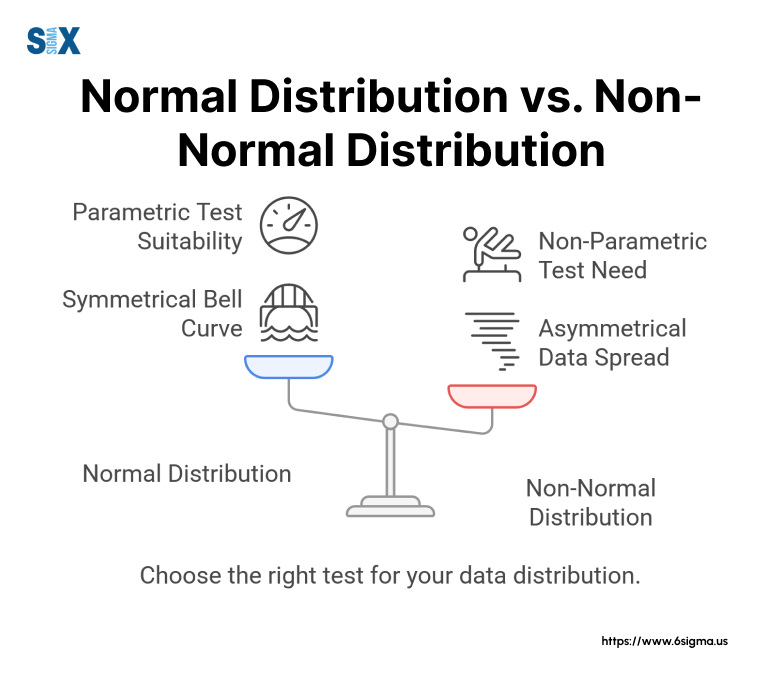

Parametric tests rely on specific assumptions about data distribution, particularly normal distribution. They work with population parameters like mean and standard deviation.

Non-parametric tests, however, focus on data rankings and don’t require assumptions about distribution shapes.

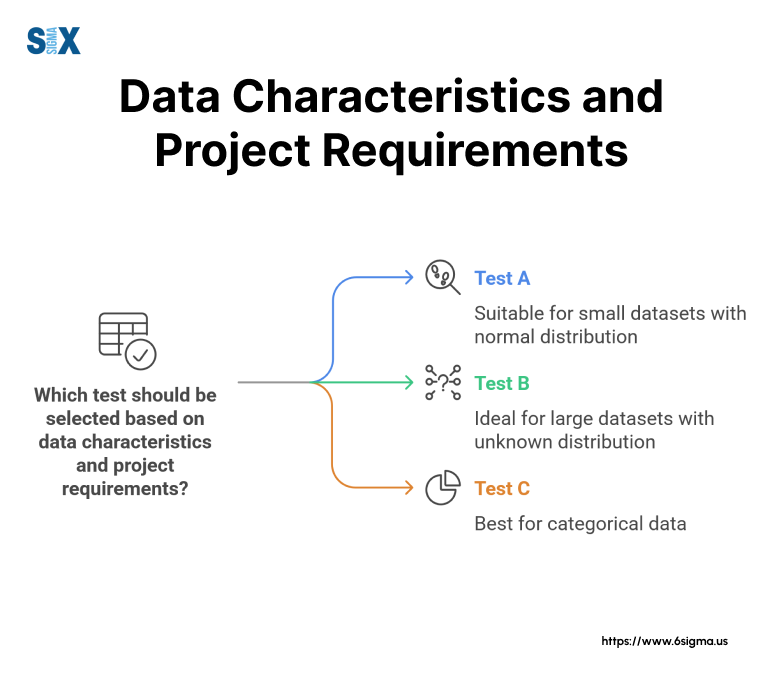

The measurement scale also influences test selection. Parametric tests work best with continuous, interval, or ratio data.

Non-parametric tests handle ordinal and nominal data effectively, making them suitable for customer satisfaction scores or quality rankings.

Selecting the Right Testing Method within Non Parametric Tests

Several factors determine whether to use parametric or non-parametric tests:

Sample Size: Large samples (n>30) often support parametric testing, while smaller samples might require non-parametric methods.

Data Type: Continuous measurements typically suit parametric tests, while ranked or categorical data needs non-parametric analysis.

Distribution Pattern: Normal distribution supports parametric testing, while skewed or unknown distributions call for non-parametric approaches.

Statistical Power and Efficiency

Parametric tests generally offer greater statistical power when their assumptions are met. However, non-parametric tests prove more reliable when dealing with:

- Outliers in the dataset

- Skewed distributions

- Small sample sizes

- Ordinal measurements

- Unknown population parameters

Practical Applications of Non Parametric Tests in Six Sigma

In Six Sigma projects, both testing methods serve valuable purposes. Parametric tests might analyze machine precision measurements, while non-parametric tests evaluate customer feedback or defect categories.

Quality improvement teams often encounter mixed data types. For example, a process improvement project might combine quantitative measurements (suitable for parametric tests) with qualitative rankings (requiring non-parametric analysis).

Test Selection Guidelines

When choosing between parametric and non-parametric tests, consider:

- Data distribution patterns

- Measurement scales used

- Sample size availability

- Required statistical power

- Project objectives

This systematic approach ensures appropriate test selection and reliable analysis results for your quality improvement initiatives.

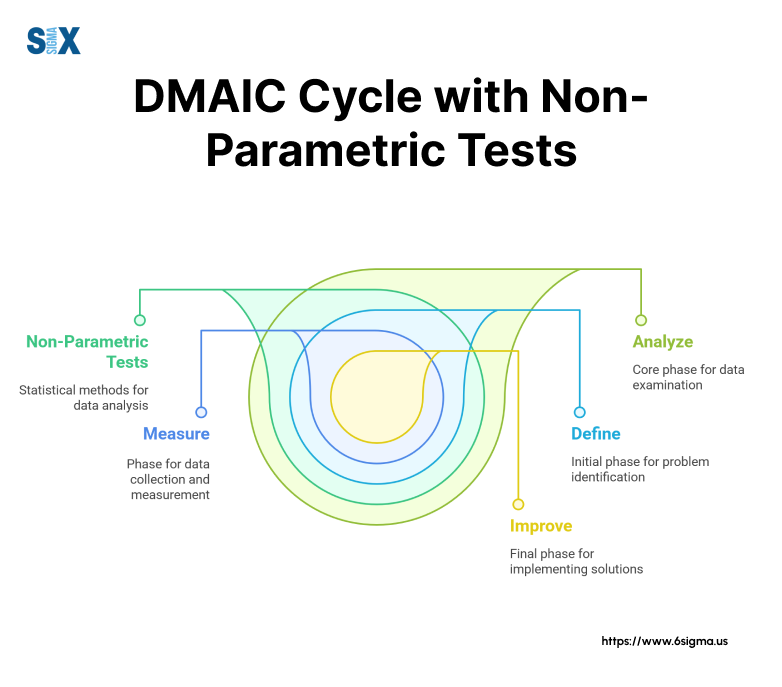

Non-Parametric Tests in The DMAIC Process

The DMAIC methodology relies heavily on data analysis to drive process improvements.

Non-parametric tests play a crucial role, particularly during the Analyze phase, where teams must extract meaningful insights from various data types.

Role of Non Parametric Tests in The Analyze Phase

During the Analyze phase, Six Sigma teams investigate root causes and validate hypotheses about process performance.

Non-parametric tests become essential when dealing with:

- Quality ratings from customer feedback

- Process capability assessments

- Defect categorization analysis

- Supplier performance evaluations

These scenarios often produce data that doesn’t follow normal distribution patterns, making non-parametric tests the most reliable analysis method.

Supporting Process Improvement Decisions

Non-parametric tests help teams make informed decisions about process changes.

For example, the Kruskal-Wallis test might evaluate differences between multiple suppliers’ performance levels, while the Mann-Whitney test could compare two different process conditions.

Quality improvement teams use these tests to:

- Validate improvement opportunities

- Quantify process variations

- Identify significant factors

- Prioritize improvement actions

Case Study: Manufacturing Process Improvement

A manufacturing facility faced challenges with inconsistent product quality across different shifts. Traditional parametric analysis proved unsuitable due to non-normal data distribution.

The team employed the Kruskal-Wallis test to analyze quality scores across shifts.

Results revealed significant differences between shift performances, leading to standardized training programs and improved quality metrics.

This case demonstrates how non-parametric tests support data-driven decision-making in real-world scenarios.

Discover the Art of Identifying True Process Problems!

Implementation of Non Parametric Tests in Research and Analysis

Six Sigma practitioners integrate non-parametric tests into their research methodology through:

- Statistical software applications

- Data collection planning

- Analysis validation procedures

- Results interpretation guidelines

These structured approaches ensure reliable conclusions from process improvement studies.

Measuring Success and Impact

Teams track improvement success using non-parametric methods to:

- Monitor process changes

- Validate improvement impacts

- Document statistical significance

- Support control phase metrics

This systematic approach helps maintain gains achieved through process improvements while providing statistical validation of results.

The strategic application of non-parametric tests throughout the DMAIC process ensures reliable analysis and sustainable improvements, particularly when dealing with non-normal or ranked data in quality improvement projects.

Become a data-driven problem-solving expert!

Elevate Your Process Improvement Skills with Six Sigma Green Belt Certification!

Practical Applications of Non-Parametric Tests

Six Sigma projects frequently encounter situations where non-parametric tests provide the most reliable analysis methods.

These practical applications demonstrate how these tests drive process improvements across various industries.

Manufacturing Quality Control

Manufacturing environments regularly use non-parametric tests to evaluate process changes.

For instance, a medical device manufacturer employed the Mann-Whitney test to compare defect rates between two assembly methods.

This analysis helped identify the superior process while accounting for non-normal data distribution.

Service Industry Applications

Customer satisfaction ratings often require non-parametric analysis due to their ordinal nature. A call center utilized the Kruskal-Wallis test to evaluate customer feedback across different service teams.

The results guided training programs and process standardization efforts, leading to improved satisfaction scores.

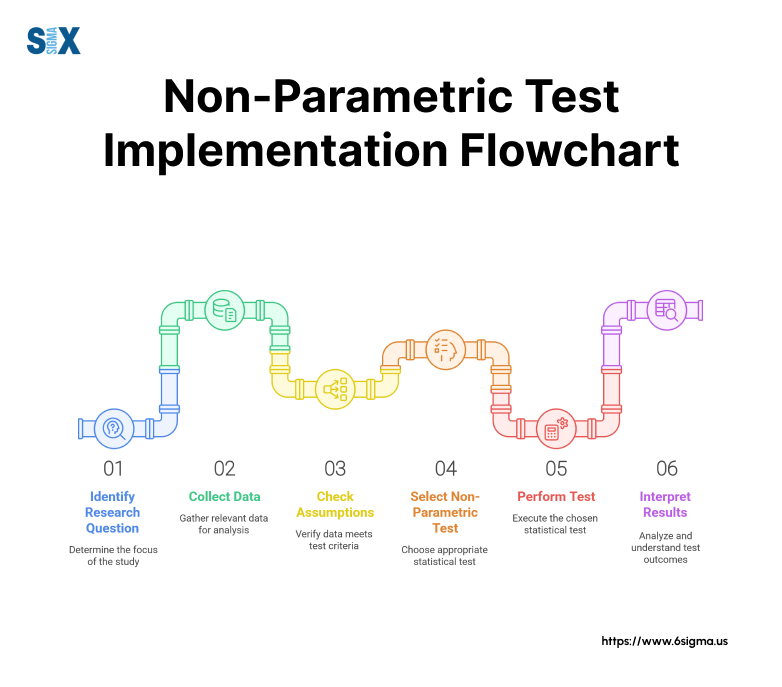

Implementation Guide of Non Parametric Tests for Process Improvement

- Data Collection Phase

– Gather relevant process metrics

– Document measurement methods

– Ensure adequate sample sizes

– Validate data quality - Analysis Preparation

– Check data distribution patterns

– Select appropriate test methods

– Prepare data formatting

– Set up statistical software - Test Execution

– Run initial analysis

– Validate test assumptions

– Document preliminary results

– Review statistical significance - Results Interpretation

– Analyze test outputs

– Compare against project goals

– Identify improvement opportunities

– Prepare recommendation reports

Common Challenges and Solutions

Small Sample Sizes: When data points are limited, use exact methods rather than approximations. The Wilcoxon exact test provides more reliable results for small samples than normal approximations.

Mixed Data Types: Projects often involve both parametric and non-parametric data. Create separate analysis streams for different data types while maintaining overall project cohesion.

Stakeholder Understanding: Many stakeholders struggle with statistical concepts. Use visual representations and clear explanations to communicate test results effectively.

Quality Improvement Case Study

A pharmaceutical company faced challenges with batch consistency. Traditional analysis methods proved unsuitable due to non-normal distribution patterns.

The quality team implemented the Mood’s median test to compare batch variations, leading to:

- Identified critical process factors

- Standardized operating procedures

- Reduced batch rejections

- Improved process capability

Best Practices for Implementation of Non Parametric Tests

Successful implementation of non-parametric tests requires:

- Clear project objectives

- Well-defined measurement systems

- Proper test selection criteria

- Robust data collection methods

- Thorough results documentation

These practical applications demonstrate how non-parametric tests support data-driven decision-making in real-world process improvement scenarios.

The structured approach ensures reliable analysis and sustainable improvements across various business contexts.

Statistical Software Tools for Non-Parametric Analysis

Modern statistical software packages provide powerful tools for conducting non-parametric tests.

These platforms offer various features that help Six Sigma practitioners analyze data efficiently and generate reliable results.

Minitab for Non-Parametric Analysis

Minitab remains the preferred choice for many Six Sigma professionals. The software provides dedicated modules for non-parametric tests, including built-in assistants that guide users through test selection and execution.

Key features include automated distribution checking, graphical analysis tools, and detailed output reports.

Master Non-Parametric Statistical Analysis with Minitab!

R Programming Environment

R offers flexible and powerful options for non-parametric statistical analysis. This open-source platform provides extensive statistical packages and customization capabilities.

Users can create specialized scripts for repeated analyses and generate detailed visualization of results.

The stats package in R includes functions for:

- Wilcoxon rank tests

- Kruskal-Wallis analysis

- Mann-Whitney comparisons

- Custom test implementations

SPSS Statistical Package

SPSS delivers user-friendly interfaces for non-parametric testing while maintaining analytical power.

The software excels in handling large datasets and provides clear output formatting. Its point-and-click interface makes it accessible for users with varying statistical expertise.

Excel Techniques and Add-ins

Microsoft Excel, while not primarily statistical software, offers basic non-parametric analysis capabilities. Add-ins and custom functions extend these capabilities for simple analyses.

Excel proves particularly useful for data preparation and preliminary analysis before using specialized statistical software.

Looking Ahead

Non-parametric tests continue evolving with advancing technology and analytical methods. Future developments focus on:

Emerging Trends

Machine learning integration enhances non-parametric analysis capabilities. Advanced algorithms help identify patterns and relationships in complex datasets, while automated test selection systems improve analysis accuracy.

Industry Applications of Non Parametric Tests

Digital transformation drives new applications for non-parametric tests. Industry 4.0 initiatives generate diverse data types, requiring robust analysis methods.

These tests increasingly support real-time process monitoring and adjustment decisions.

Key Takeaways

Non-parametric tests provide essential tools for modern process improvement. Their flexibility and reliability make them invaluable for:

- Analyzing diverse data types

- Supporting decision-making processes

- Validating improvement initiatives

- Maintaining process control

Moving Forward

The integration of non-parametric tests with advanced analytics platforms continues expanding their applications. Quality improvement professionals should:

- Stay current with software developments

- Understand test selection criteria

- Maintain statistical knowledge

- Apply appropriate analysis methods

This evolution ensures non-parametric tests remain vital tools in the quality improvement landscape, supporting data-driven decision-making across industries and applications.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs