Hazard and Operability Study (HAZOP): A Guide for Risk Assessment

Hazard and Operability study/assessment emerges as a principled partner for risk surveying – especially within material/workflow-sensitive arenas.

Hazard and Operability Study (HAZOP) describes a systematic yet adaptable approach pinpointing feasible challenges and difficulties, involving finer parts examination called “nodes”.

Key Highlights

- Definition and purpose of Hazard and Operability Study (HAZOP)

- Applications across industries

- Hazard and Operability Study (HAZOP) methodology

- Examination phase

- Best practices and challenges

- Regulatory and industry compliance

- Integration with other risk management tools

- Future trends and developments

What defines Hazard and Operability Study? (HAZOP)

Hazard and Operability Study (HAZOP) offers a lucid yet thorough framework for surveying complex systems/processes and identifying personnel, assets, or environmental risks proactively.

A widely respected methodology within controlled surroundings stewardship.

The primary aim involves preemptively detecting, comprehending, and lessening deviations’ consequences for safety, reliability, and cost wherever complexity interweaves sensitive realities.

For prudent caretakers committed to performance and relationships safeguarded through challenges jointly overcome, HAZOP emerges as a committed ally.

Organizations often pair HAZOP with structured methodologies like Six Sigma certification programs, which train professionals in systematic risk identification and mitigation.

Progress springs from insights sustaining well-being wherever sensitive interfaces demand flexible yet judicious navigation as one.

Some key applications of Hazard and Operability Study (HAZOP) include:

- Process safety management: HAZOP is a key component of process safety management (PSM) programs, as mandated by regulatory bodies like OSHA for industries dealing with hazardous materials, and professionals often pursue a six sigma green belt certification to strengthen their PSM skills.

- Risk assessment: HAZOP serves as a comprehensive risk assessment tool, enabling organizations to identify and evaluate potential hazards and operability issues systematically.

- Hazard identification: HAZOP is widely used for proactive hazard identification, particularly in industries with inherent risks, such as chemical plants, oil and gas facilities, nuclear power plants, and pharmaceutical manufacturing.

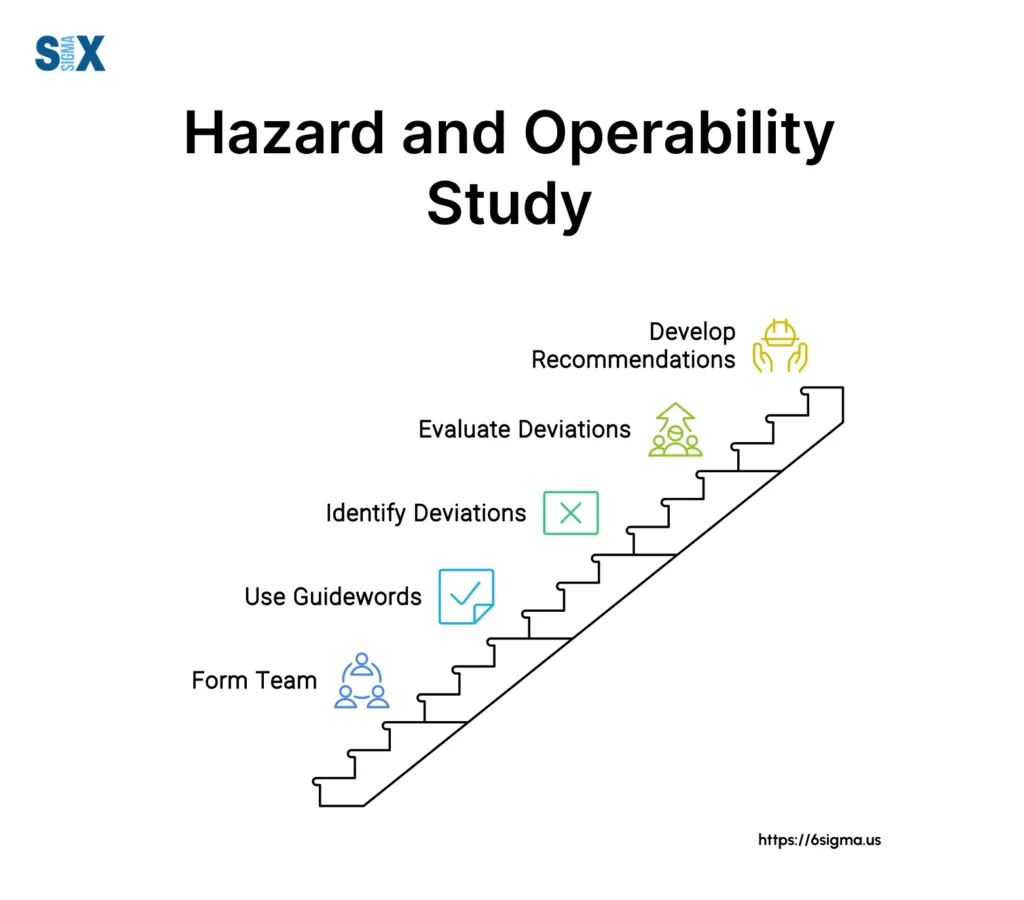

The Hazard and Operability Study (HAZOP) Methodology

A Hazard and Operability Study (HAZOP) is a collaborative effort that requires a multidisciplinary team with diverse expertise and perspectives.

The team typically comprises the following members:

- Study leader/facilitator: An experienced professional responsible for guiding the team through the HAZOP process, moderating discussions, and ensuring the accuracy and clarity of the findings and recommendations.

- Recorder/scribe: Responsible for documenting the team’s discussions, identified hazards, consequences, causes, safeguards, and recommended actions.

- Design engineer: Provides in-depth knowledge of the system or process under review, explaining the design intent and how deviations can occur.

- Operator/user: Offers operational insights, helping the team understand the practical implications of deviations and their potential consequences.

- Subject matter experts: Specialists from various disciplines (e.g., safety, maintenance, quality, environmental) who provide relevant expertise and insights.

To systematically identify potential deviations from the design or operational intent, the HAZOP team applies a set of predefined guidewords to various process parameters.

Guidewords are carefully selected terms that prompt the team to consider specific types of deviations, such as “no”, “more”, “less”, “reverse”, and “other than”.

Process parameters can include flow, temperature, pressure, level, composition, and other critical variables that define the system’s intended operation.

By combining guidewords and process parameters, the team can systematically explore deviations and their potential consequences.

Defining the Scope and Objectives of Hazard and Operability Study (HAZOP)

The first step in a Hazard and Operability Study (HAZOP) analysis is to clearly define the scope and objectives of the study.

This includes identifying the system or process to be analyzed, the study boundaries, and any key assumptions or constraints.

Setting clear objectives ensures that the team remains focused and aligns their efforts toward achieving the desired outcomes.

Preparing for the Hazard and Operability Study (HAZOP)

Proper preparation is crucial for a successful Hazard and Operability Study (HAZOP).

This involves collecting and reviewing relevant data and documentation, such as process flow diagrams, piping and instrumentation diagrams (P&IDs), material safety data sheets (MSDS), and operating procedures.

The team must also agree on the recording format and tools to be used during the study, which may include specialized HAZOP software or spreadsheets.

Examination Phase

The examination phase is the core of the Hazard and Operability Study (HAZOP) process. It involves breaking down the system or process into smaller components, known as nodes, and systematically analyzing each node for potential deviations.

For each node, the team applies the selected guidewords and process parameters to identify possible deviations from the design intent.

Once a deviation is identified, the team explores its potential consequences, causes, and existing safeguards or controls.

Documentation and follow-up (recording, action tracking, re-study)

Thorough documentation is essential throughout the HAZOP process.

The team records the identified deviations, consequences, causes, and recommended actions in a standardized format.

This documentation serves as a reference for future action and facilitates follow-up activities, such as implementing recommended safeguards, tracking action items, and potentially re-studying parts of the system if significant changes are made.

Hazard and Operability Study (HAZOP) in the Process Industries

Hazard and Operability Study (HAZOP) has its roots in the chemical industry, where it is widely used to analyze complex processes involving hazardous materials.

In chemical plants, HAZOP is particularly valuable for assessing batch reactions, piping systems, and instrumentation diagrams (P&IDs).

By conducting a thorough Hazard and Operability Study (HAZOP) analysis, potential hazards such as leaks, runaway reactions, or instrumentation failures can be identified and mitigated before they pose a risk to personnel, equipment, or the environment.

The oil and gas industry, with its inherent risks and complex processes, heavily relies on HAZOP for risk management.

HAZOP studies are commonly performed on offshore platforms, refineries, and other oil and gas facilities to identify potential hazards associated with hydrocarbon processing, transportation, and storage.

This includes identifying risks related to equipment failure, loss of containment, and environmental impacts.

In the pharmaceutical industry, HAZOP plays a crucial role in ensuring product quality and patient safety.

The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) Q9 Guideline on Quality Risk Management endorses the use of HAZOP as a risk assessment tool.

By conducting HAZOP studies, pharmaceutical manufacturers can identify potential hazards and operability issues that could compromise product quality, contamination risks, or regulatory compliance.

The nuclear power industry has stringent safety requirements due to the potential for catastrophic consequences.

HAZOP studies are performed on nuclear power plants to identify potential operability problems that could lead to equipment failures, loss of control, or environmental hazards.

These hazards could result in radioactive material release, putting personnel and the surrounding communities at risk.

Best Practices and Challenges for Hazard and Operability Study (HAZOP)

Effective team dynamics and consideration of human factors are crucial for a successful Hazard and Operability Study (HAZOP).

The multidisciplinary nature of the HAZOP team means that diverse perspectives and communication styles must be managed effectively.

The study leader plays a vital role in facilitating open and constructive discussions, fostering an environment of trust and collaboration, and ensuring that all team members contribute their expertise.

One of the key challenges in a HAZOP is accurately identifying potential hazards and evaluating their consequences.

This requires a deep understanding of the system or process, as well as the ability to think critically and anticipate potential scenarios.

Our Root Cause Analysis training program, a core component of Six Sigma methodologies, can equip leaders to dissect deviations like these systematically.

The team must consider not only the immediate consequences but also the potential cascading effects and long-term implications of identified hazards.

Once hazards and their consequences have been identified, the Hazard and Operability Study (HAZOP) team must develop appropriate safeguards and risk mitigation strategies.

This may involve recommending changes to the system design, implementing additional controls or barriers, revising operating procedures, or providing training to personnel, such as our six sigma certification program to enhance process improvement skills.

The team must carefully evaluate the effectiveness and feasibility of proposed safeguards to ensure they adequately address the identified risks.

Operator Involvement and Operational Experience

Involving experienced operators and leveraging their operational knowledge is crucial for a successful Hazard and Operability Study (HAZOP).

Operators often have unique insights into the practical realities of the system or process, including potential deviations, workarounds, or operational constraints that may not be apparent from design documentation alone, which can further be enhanced through our root cause analysis training program.

Their input can help the team identify hazards that may be overlooked by relying solely on theoretical knowledge.

Worst-case Consequence Identification with Hazard and Operability Study (HAZOP)

Some organizations may be hesitant to identify and document worst-case consequences during a Hazard and Operability Study (HAZOP), assuming that existing safeguards will prevent such scenarios from occurring.

However, this approach can be shortsighted and potentially overlook critical risks.

It is essential to identify and understand the worst-case consequences of potential hazards, even if the likelihood of occurrence is low.

This information is crucial for developing appropriate safeguards and contingency plans.

Team Concentration and Meeting Duration

HAZOP studies can be mentally demanding, requiring sustained focus and concentration from team members.

Prolonged meetings or sessions without adequate breaks can lead to fatigue, reducing the team’s effectiveness in identifying hazards and considering potential scenarios.

It is essential to schedule meetings appropriately, allowing for regular breaks and limiting session durations to maintain team engagement and productivity.

Resolving Design Disagreements with Hazard and Operability Study (HAZOP)

During a Hazard and Operability Study (HAZOP), disagreements may arise among team members regarding the system design, operational procedures, or the interpretation of potential hazards and consequences.

It is important to have a mechanism in place for resolving such disagreements promptly and objectively.

The study leader should facilitate constructive discussions and, if necessary, involve additional subject matter experts or refer to authoritative sources to reach a consensus.

Conclusion

Hazard and Operability assessment proves a potent risk evaluation partner, ensuring controlled settings function soundly and efficiently.

By perceptively pinpointing potential concerns, Hazard and Operability Study (HAZOP) empowers preemptive measures shielding personnel, resources, and environments from harm.

As industries evolve endlessly and understanding progresses, HAZOP adapts judiciously to fresh textures. Specialized applications like software surveillance widen its reach.

HAZOP combined with Failure Mode investigation, Fault Tree, or methodologies like lean fundamentals unveils deeper risk comprehension and solutions.

Compliance with regulatory and industry ethics stays crucial. Hazard and Operability Study (HAZOP) plays a vital role in meeting standards wherever sensitive interfaces demand prudent yet nimble navigation together.

Its principled yet flexible approach guards proactively. Progress springs from shared insights sustaining quality relationships and performance wherever complexity interconnects realities impacting lives.

Hazard and Operability Study (HAZOP) proves a committed ally for journeys ahead.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs