DMADV: The Definitive Guide to Six Sigma for New Product & Process Design

DMADV is like a trusty roadmap that guides you through the entire journey, from understanding what your customers truly want to creating a game-changing solution that exceeds their expectations.

DMADV isn’t just another buzzword or complicated process – it’s a structured, step-by-step approach that breaks down the daunting task of innovation into manageable phases.

Key Highlights

- Overview of the DMADV methodology and its five distinct phases

- Exploration of each phase

- Insights into the critical role of customer requirements and the voice of the customer (VOC)

- Exploration of advanced statistical and analytical tools

- Practical examples and case studies

- Comparison between DMADV and DMAIC

- Best practices for effective project management, team selection, and change management

- Emerging trends and future advancements in DMADV

Introduction to DMADV

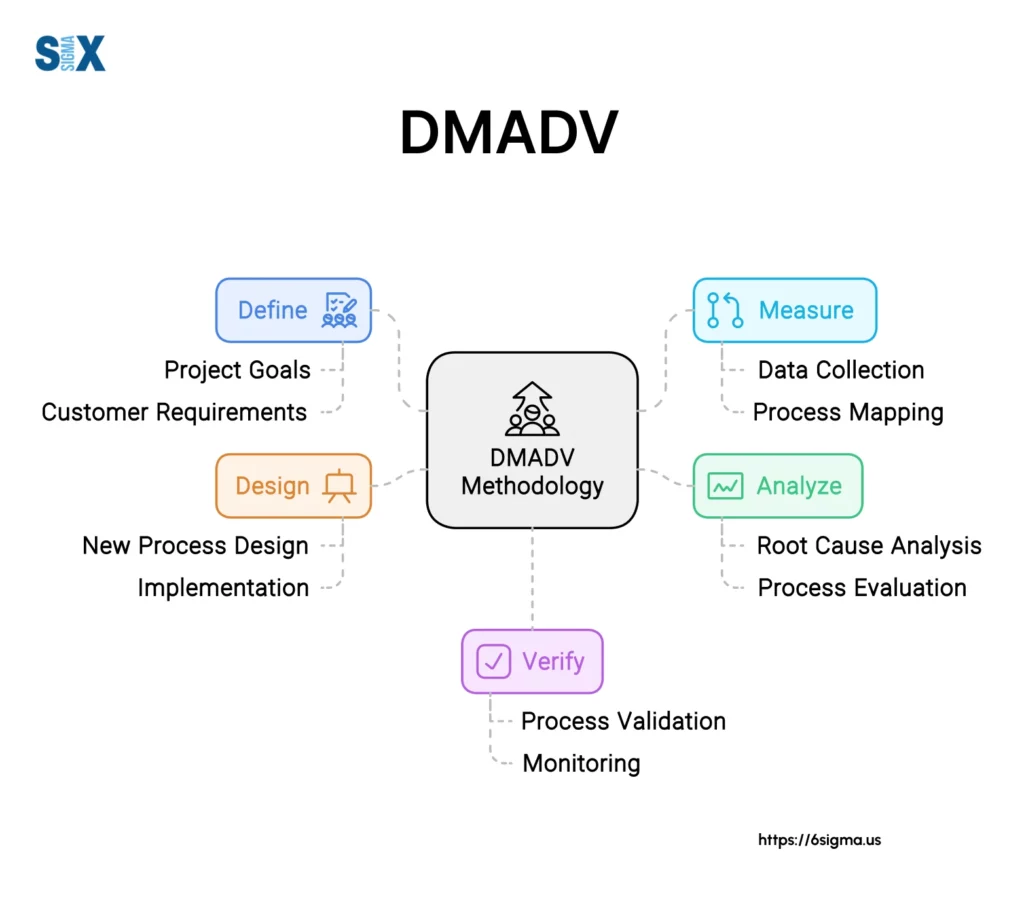

DMADV, an acronym for Define, Measure, Analyze, Design, and Verify, is a powerful Six Sigma methodology that provides a structured framework, covered in our Six Sigma certification programs, for developing new products, services, or processes.

This data-driven approach is designed to guide teams through the entire innovation lifecycle, from identifying customer requirements to validating the final implementation.

DMADV is a systematic and disciplined process that ensures every aspect of the development effort is meticulously planned, executed, and evaluated.

It begins by defining the project’s objectives, customer needs, and success criteria.

The Five Phases of DMADV

Define Phase

The Define phase sets the foundation for the entire DMADV project by rigorously identifying and documenting customer requirements.

This critical step involves gathering the voice of the customer (VOC) data through various methods, such as surveys, focus groups, and interviews.

By deeply understanding the target audience’s needs, expectations, and pain points, teams can better align their efforts to deliver solutions that truly resonate with customers.

Measure Phase

In the Measure phase, teams focus on identifying and measuring the critical to quality (CTQ) characteristics that directly impact customer satisfaction.

These CTQs are derived from the customer requirements identified in the Define phase and serve as the foundation for evaluating the success of the new product, service, or process.

By establishing clear metrics and measurement systems, teams can objectively assess performance and make data-driven decisions throughout the development process.

Analyze Phase

The Analyze phase is focused on identifying the root causes of potential problems or challenges that may arise during the development process.

By conducting thorough root cause analysis, teams can uncover underlying issues and address them proactively, rather than reacting to symptoms or surface-level problems.

This proactive approach helps to mitigate risks and increase the likelihood of a successful outcome.

Once root causes have been identified, the Analyze phase involves exploring various design alternatives that could potentially address the identified issues.

Design Phase

Building upon the insights and decisions made in the Analyze phase, the Design phase begins with the development of conceptual designs.

These initial designs translate the selected design alternatives into tangible concepts, often involving sketches, wireframes, or low-fidelity prototypes.

The goal at this stage is to explore various design possibilities and refine the concepts before moving into more detailed design work.

Verify Phase

The Verify phase is focused on validating the final design through rigorous testing and evaluation.

This often involves conducting pilot tests or limited production runs to assess the performance of the new product, service, or process under real-world conditions.

During this phase, teams collect data on key performance indicators, identify any remaining issues or areas for improvement, and make necessary adjustments to ensure the final offering meets or exceeds customer requirements.

Applications of DMADV

One of the primary applications of the DMADV methodology is in the realm of new product development.

By following the structured DMADV process, organizations can ensure that new products are designed and developed to meet specific customer needs while minimizing defects and maximizing quality.

This approach is particularly valuable in industries where product innovation is critical, such as consumer electronics, automotive, and healthcare.

DMADV is not limited to product development; when combined with the fundamentals of Lean, it can drive process redesigns that eliminate waste and boost efficiency.

By analyzing current processes, identifying root causes of inefficiencies or quality issues, and developing new process designs, organizations can significantly improve their operational performance, reduce waste, and enhance overall productivity.

In the service industry, DMADV can be leveraged to develop and launch new service offerings that meet evolving customer expectations.

By carefully defining customer requirements, analyzing market trends, and designing innovative service models, organizations can differentiate themselves from competitors and deliver superior customer experiences.

The versatility of the DMADV methodology has been demonstrated across a wide range of industries, including:

- Manufacturing: Developing new production processes or product lines to meet changing market demands.

- Healthcare: Designing innovative medical devices, treatment protocols, or patient care systems.

- Finance: Introducing new financial products, services, or risk management processes.

- Retail: Optimizing supply chain processes or developing new consumer experiences.

- Technology: Designing new software applications, digital platforms, or IT infrastructure solutions.

DMADV vs. DMAIC

While both DMADV and DMAIC are core Six Sigma methodologies taught in our Six Sigma certification courses, they differ in their primary focus and application.

The following table highlights the key differences between the two:

| Aspect | DMADV | DMAIC |

|---|---|---|

| Purpose | Develop new products, services, or processes | Improve existing processes |

| Focus | Innovation and new design | Defect reduction and process optimization |

| Approach | Proactive and customer-driven | Reactive and problem-solving |

| Project Type | New product/service development, major process redesign | Continuous improvement, incremental changes |

| Phase Differences | Design and Verify phases | Improve and Control phases |

The choice between DMADV and DMAIC depends on the specific objectives and context of the project:

- Use DMADV when developing new products, services, or processes to meet emerging customer needs or market demands.

- Use DMAIC when the goal is to improve or optimize an existing process that is underperforming or has known defects or inefficiencies.

In some cases, organizations may employ both methodologies in tandem, using DMADV to develop a new offering and then transitioning to DMAIC for continuous improvement and optimization once the initial implementation is complete.

While DMADV and DMAIC are distinct methodologies, they are complementary and can be integrated to drive continuous improvement within an organization.

The output of a DMADV project, such as a new product or process, can serve as the input for a subsequent DMAIC project aimed at optimizing and refining the implementation.

Best Practices and Tools for DMADV Implementation

Successful DMADV implementation relies heavily on assembling a cross-functional team with the right mix of skills, expertise, and experience.

This team should include representatives from various departments, such as engineering, operations, marketing, and customer service, to ensure a holistic approach to product or process development.

Throughout the DMADV process, data collection and analysis play a critical role in informing decision-making and validating the effectiveness of the new product, service, or process.

Teams should be equipped with a range of data collection tools, such as surveys, focus groups, and process monitoring systems, as well as statistical analysis techniques like hypothesis testing, regression analysis, and design of experiments (DOE).

In the Design phase, teams may leverage various tools and software to aid in the development and visualization of conceptual and detailed designs.

This may include computer-aided design (CAD) software, 3D modeling tools, prototyping software, and virtual simulation environments.

The choice of tools will depend on the specific project requirements and the industry in which the organization operates.

Given the inherent risks associated with new product or process development, it is crucial to implement robust risk management strategies throughout the DMADV process.

This may involve techniques such as failure mode and effects analysis (FMEA), risk assessment matrices, and contingency planning.

Effective risk management ensures that potential issues are identified and mitigated proactively, reducing the likelihood of project delays or failures.

Conclusion

DMADV offers a principled yet adaptable framework guiding organizations in new creation journeys resourcefully.

The five phases sustain focus on comprehension, evidence, multidimensional study, and verification – harnessing talents where customer requisites inspire.

Communities embracing DMADV encounter numerous gifts, including:

- Client approaches cultivate fulfillment

- Reduced market arrival timeframe

- Performance and natural refinement

- Efficiency and savings growth

- Innovation distinctive qualities

- Vision-guided coordination

The future holds advanced tools like smart analytics, AI, and testing methods for better predictions and solutions.

Companies aiming to stay ahead and meet customer needs should adopt the DMADV process.

Training, resources, and company culture must change to focus on customer satisfaction and long-term success. Investing in Six Sigma certification programs for teams ensures alignment with customer-centric, data-driven cultures.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs