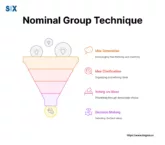

Nominal Group Technique: A Strategic Decision-Making Tool in Six Sigma

The Nominal Group Technique (NGT) stands as a structured method for group decision-making that transforms individual ideas into actionable solutions. This systematic approach helps teams prioritize options and reach consensus while ensuring every voice gets heard. Key Highlights What is Nominal Group Technique? The Nominal Group Technique (NGT) represents a structured decision-making method that organizations […]