Understanding Turnaround Time: A Comprehensive Guide

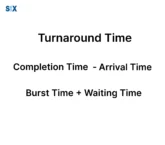

Time is a precious commodity. Whether you’re a manufacturer trying to optimize production cycles, a logistics provider aiming to speed up deliveries, or a service provider wanting to boost customer satisfaction, truly grasping turnaround time could be huge. Turnaround time, or TAT for short, measures the duration between a process starting and finishing. It encompasses […]