What are Agile Tools and How to Use Them? A Complete Guide to Agile

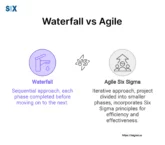

Finding the proper tools matters when employing agile practices and workflows amid speedy, ever-evolving surroundings. Agile tools produce such advantages. These facilitate central tenets like sprints, responsibilities tracking, status transparency, and endless upgrading–syncing cooperation through interoperable environments. Companies can harness flexibility focusing on enhanced client-centricity through persistent improvement and team-oriented synergy. Key Highlights What are […]