Lean Scheduling: Optimize Projects with Lean Strategies

Lean scheduling is a strategic approach that combines the principles of lean thinking with project scheduling techniques to optimize resource utilization, minimize waste, and enhance overall project efficiency.

This methodology, rooted in continuous improvement and waste reduction, has revolutionized how organizations plan and execute projects across various industries.

Key Highlights

- Core principles and benefits of lean scheduling

- Pull systems and Last Planner System implementation

- Visual management techniques for enhanced workflow

- Resource optimization and workload balancing strategies

- Lean metrics and performance measurement approaches

- Overcoming resistance to lean scheduling adoption

- Future trends in lean scheduling technologies

Understanding Lean Scheduling

Lean scheduling is a sophisticated project management approach that integrates lean thinking principles with traditional scheduling methods.

Lean scheduling aims to maximize value delivery while minimizing waste in project timelines and resource allocation.

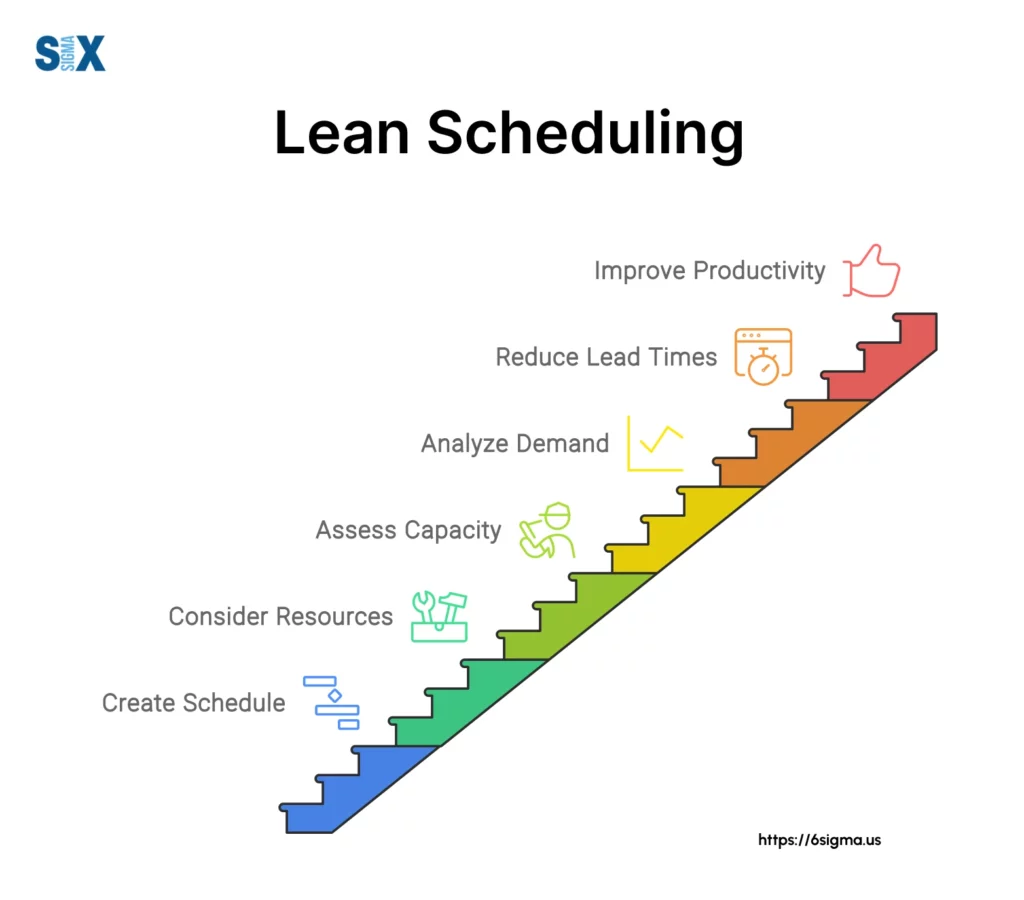

The fundamental principles of lean scheduling include:

- Value Stream Focus: Identifying and optimizing the sequence of activities that deliver value to the customer.

- Pull-based Planning: Scheduling work based on actual demand rather than forecasts.

- Continuous Flow: Ensuring smooth progression of work without unnecessary delays or bottlenecks.

- Waste Elimination: Identifying and removing non-value-adding activities from the schedule.

- Continuous Improvement: Regularly analyzing and refining the scheduling process for enhanced efficiency.

Benefits of Lean Scheduling in Project Management

There are numerous benefits of implementing lean scheduling:

- Improved Resource Utilization: By optimizing workflow, lean scheduling ensures that resources are used efficiently, reducing idle time and over allocation.

- Reduced Lead Times: The focus on continuous flow and waste elimination often results in significant reductions in project completion times.

- Enhanced Flexibility: Allows for quicker responses to changes in project scope or customer requirements.

- Increased Stakeholder Satisfaction: More accurate timelines and improved delivery lead to higher customer and team satisfaction.

- Cost Reduction: By minimizing waste and optimizing resources, lean scheduling often leads to substantial cost savings.

- Better Risk Management: The continuous improvement aspect helps in early identification and mitigation of potential risks.

Lean Scheduling vs. Traditional Scheduling Methods

Traditional scheduling methods, such as Critical Path Method (CPM) or Program Evaluation and Review Technique (PERT), often fall short in today’s dynamic project environments.

Here’s how lean scheduling differs:

- Focus: Traditional methods focus on task completion, while lean scheduling emphasizes value delivery.

- Planning Approach: Traditional methods use a push-based system, whereas lean scheduling employs a pull-based approach.

- Flexibility: It is more adaptable to changes, unlike the rigid nature of traditional methods.

- Waste Consideration: Traditional methods often overlook waste in processes.

- Continuous Improvement: It incorporates ongoing refinement, while traditional methods are more static.

Key Components of Lean Scheduling

To effectively execute it, practitioners rely on a diverse toolkit of proven methods and strategies.

These tools and techniques, honed through years of application across various industries, provide the means to optimize workflows, reduce waste, and enhance project efficiency.

Pull System and Last Planner System

The pull system is a cornerstone of lean scheduling. Instead of pushing work based on a predetermined schedule, work is pulled through the system based on actual capacity and demand.

This approach minimizes work-in-progress and reduces the risk of overproduction.

The Last Planner System (LPS) is a practical application of the pull system in project management.

It involves collaborative planning at multiple levels:

- Master Schedule: Overall project timeline

- Phase Schedule: Detailed breakdown of each project phase

- Look-ahead Plan: 3-6 week forward-looking schedule

- Weekly Work Plan: Detailed plan for the upcoming week

In my experience implementing LPS across various industries, I’ve found it particularly effective in improving workflow reliability and team collaboration.

Kanban Boards and Visual Management

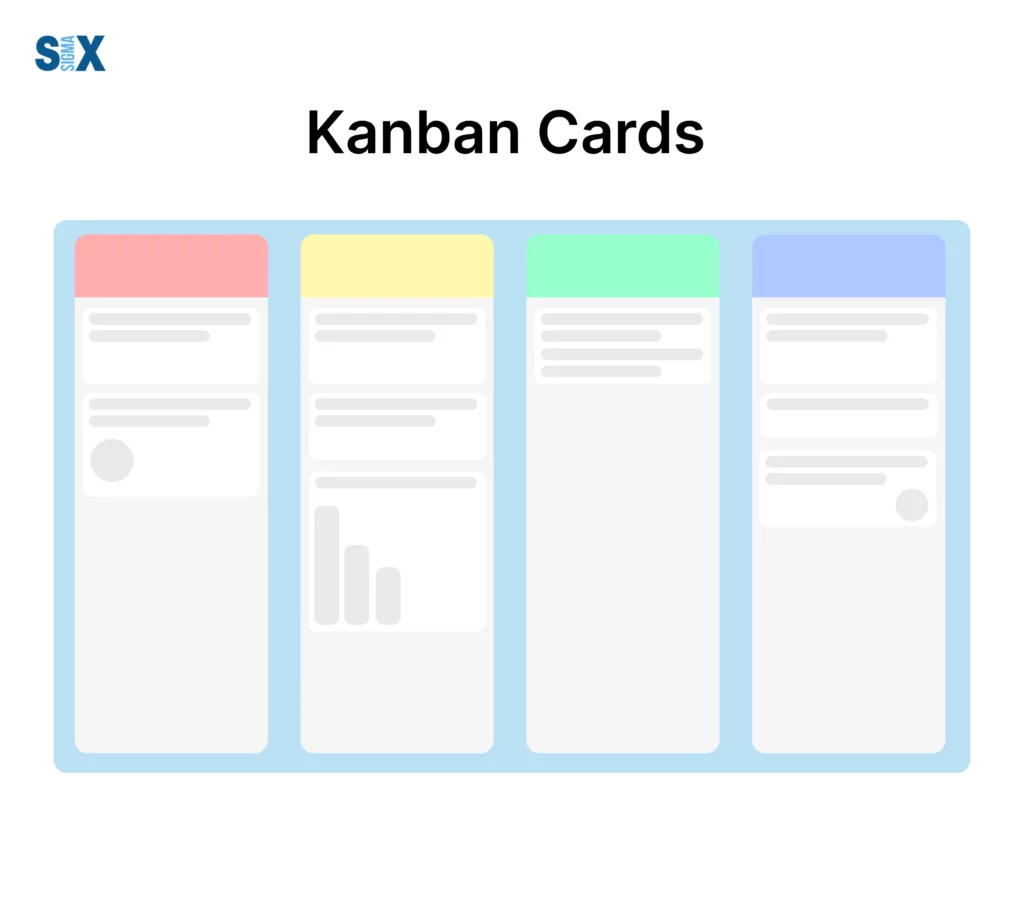

Kanban, a visual management tool, is integral to lean scheduling.

It provides a clear, visual representation of work flow, helping teams identify bottlenecks and manage work-in-progress effectively.

A typical Kanban board consists of columns representing different stages of work (e.g., To Do, In Progress, Done) and cards representing individual tasks.

This visual approach allows for quick status updates and facilitates better communication among team members.

Value Stream Mapping and Workflow Efficiency

Value stream mapping is a powerful technique for visualizing the flow of work through a project.

It helps identify value-adding activities, non-value-adding activities, and waste in the process.

By mapping out the entire value stream, teams can identify opportunities for improvement and streamline their workflows.

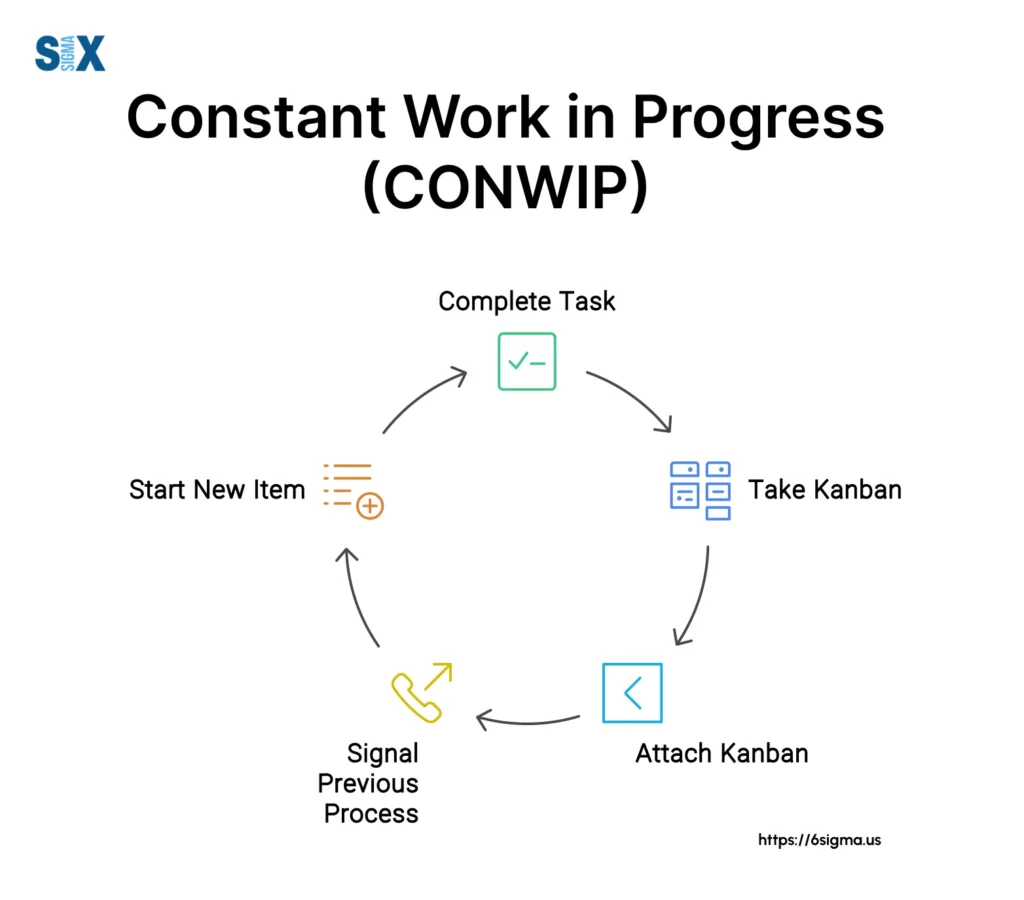

Work In Progress (WIP) Limits and Takt time

Work in Progress (WIP) limits remain crucial.

By setting a maximum number of tasks that can be in progress at any given time, teams can avoid overloading and ensure a smooth flow of work.

This approach helps prevent bottlenecks and reduces the risk of delays.

Takt time, a concept borrowed from lean manufacturing, refers to the rate at which work needs to be completed to meet customer demand.

In project management, it helps in pacing work and ensuring that the project progresses at a steady, sustainable rate.

Implementing Lean Scheduling in Projects

Transitioning from theory to practice, the implementation requires a strategic approach and a shift in organizational mindset.

Collaborative Planning and Agile Methodologies

Lean scheduling thrives on collaboration. It encourages cross-functional teams to work together in planning and executing projects.

This collaborative approach ensures that all perspectives are considered and potential issues are identified early.

Agile methodologies, with their focus on iterative development and frequent feedback, align well with the principles.

The combination of lean and agile can lead to highly responsive and efficient project management.

Resource Optimization and Workload Balancing

Effective resource management is critical in lean scheduling. It involves:

- Identifying and eliminating resource conflicts

- Balancing workloads to prevent overburden

- Ensuring that the right resources are available at the right time

Proper resource optimization can lead to significant improvements in project efficiency and team morale.

Task Prioritization and Time Boxing Techniques

Prioritization is key in lean scheduling. Techniques like the MoSCoW method (Must have, Should have, Could have, Won’t have) can be used to ensure that the most critical tasks are addressed first.

Time boxing, or allocating fixed time periods to activities, helps maintain focus and prevent scope creep. It’s particularly useful in managing complex projects with multiple inter-dependencies.

Continuous Improvement and Kaizen Events

Continuous improvement is at the heart of lean scheduling.

Regular retrospectives and Kaizen events provide opportunities to reflect on processes and identify areas for improvement.

Kaizen events, or rapid improvement workshops, can be particularly effective in addressing specific challenges in the scheduling process.

These focused, short-term efforts can lead to significant improvements in efficiency and effectiveness.

Lean Scheduling Tools and Techniques

To effectively execute it, practitioners rely on a diverse toolkit of proven methods and strategies.

These tools and techniques, honed through years of application across various industries, provide the means to optimize workflows, reduce waste, and enhance project efficiency.

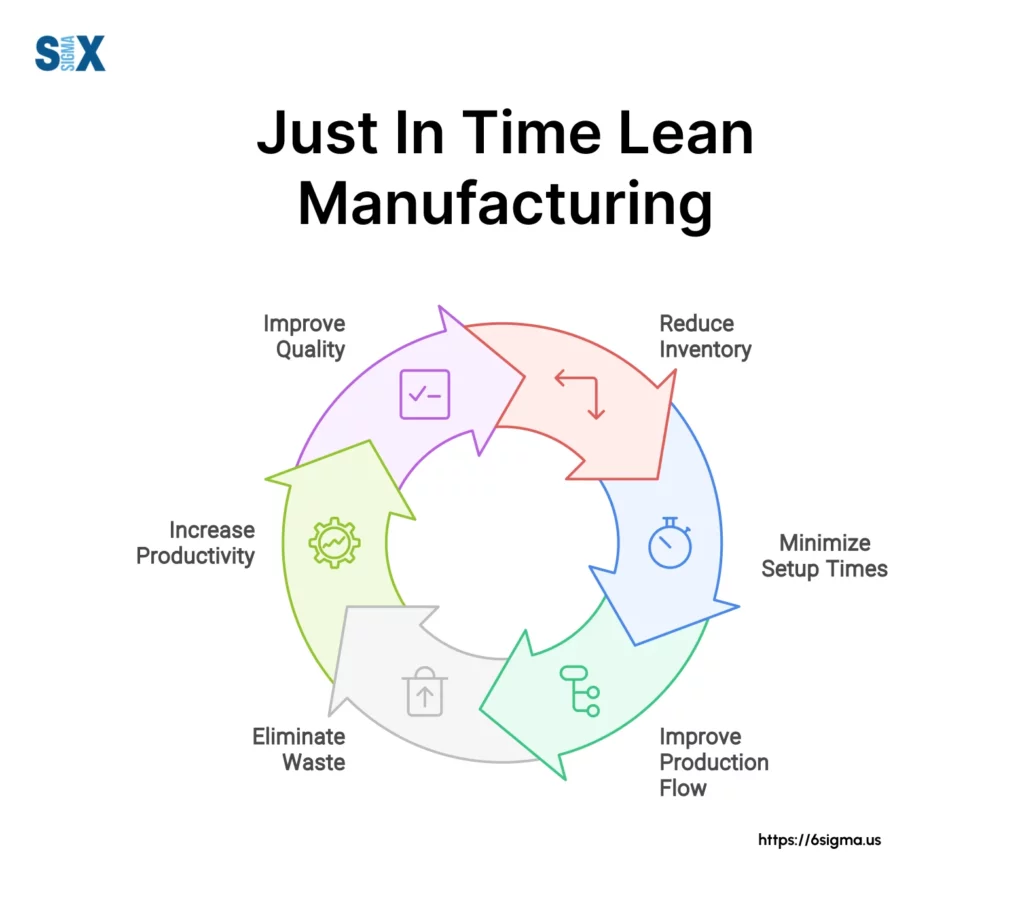

Just-in-time production and lean construction practices

Just-in-time (JIT) production, a key lean principle, can be applied to project scheduling.

It involves delivering resources and starting tasks only when they’re needed, reducing waste and improving efficiency.

Lean construction practices, which I’ve implemented in various projects, apply lean principles to construction management.

These include:

- Last Planner System for collaborative planning

- Pull planning for efficient resource allocation

- Daily huddles for improved communication and problem-solving

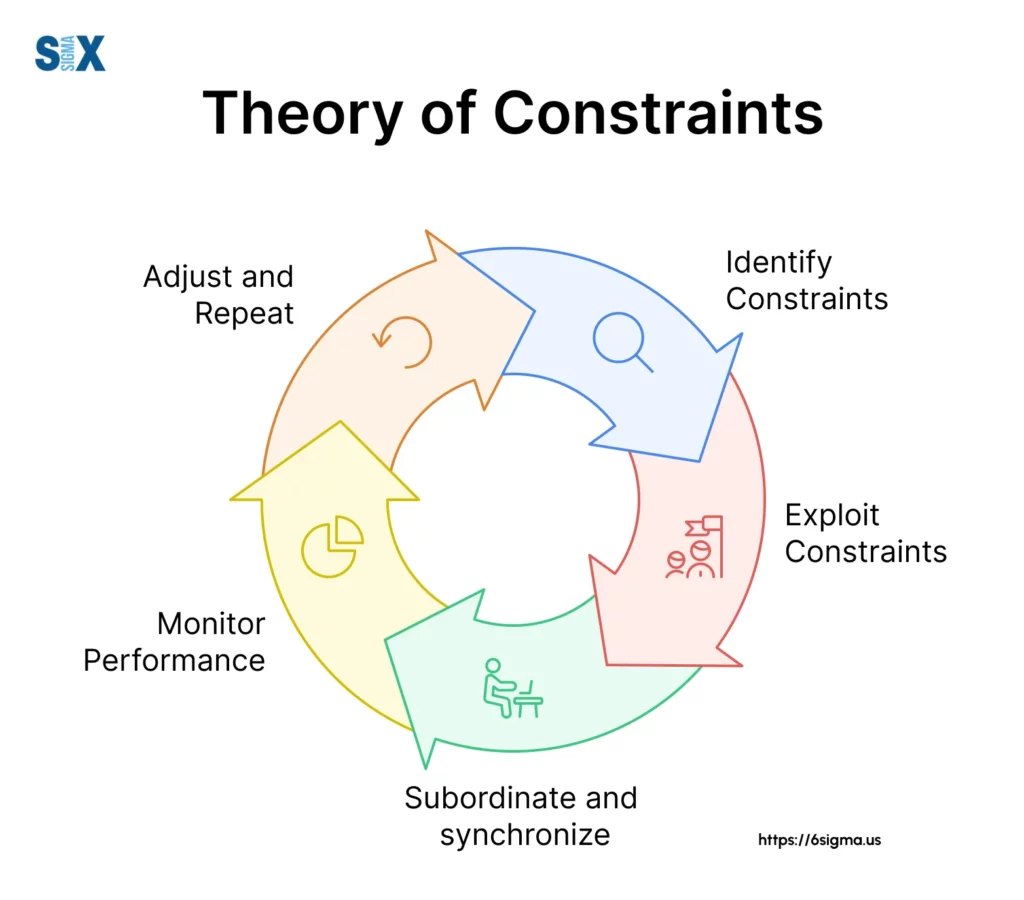

Constraint Analysis and Bottleneck Identification

Identifying and managing constraints is crucial in lean scheduling.

The Theory of Constraints (TOC) provides a framework for identifying bottlenecks in the project workflow and focusing improvement efforts where they’ll have the most impact.

Techniques like the Five Focusing Steps can be used to systematically identify and address constraints:

- Identify the constraint

- Exploit the constraint

- Subordinate everything else to the constraint

- Elevate the constraint

- Repeat the process

Cycle Time and Lead time Reduction Strategies

Reducing cycle time (the time it takes to complete a task) and lead time (the total time from start to finish) is a key focus. Strategies include:

- Eliminating non-value-adding activities

- Improving handoffs between tasks

- Implementing parallel processing where possible

- Reducing batch sizes

Six Sigma Integration for Enhanced Productivity

As a Six Sigma Master Black Belt, I’ve found that integrating Six Sigma methodologies with lean scheduling can lead to powerful results. Six Sigma tools like DMAIC (Define, Measure, Analyze, Improve, Control) can be used to systematically improve scheduling processes and reduce variability.

Statistical process control techniques can also be applied to monitor and improve the stability and predictability of project schedules.

Measuring and Improving Lean Scheduling Performance

Measuring performance is crucial. Key metrics include:

- Cycle Time: Time to complete a task or process

- Lead Time: Total time from start to finish

- Throughput: Number of tasks completed in a given time

- Work in Progress (WIP): Number of tasks currently being worked on

- Planned Percent Complete (PPC): Percentage of planned tasks completed

- Cumulative Flow: Visual representation of work progress over time

These metrics provide insights into the efficiency and effectiveness of the scheduling process.

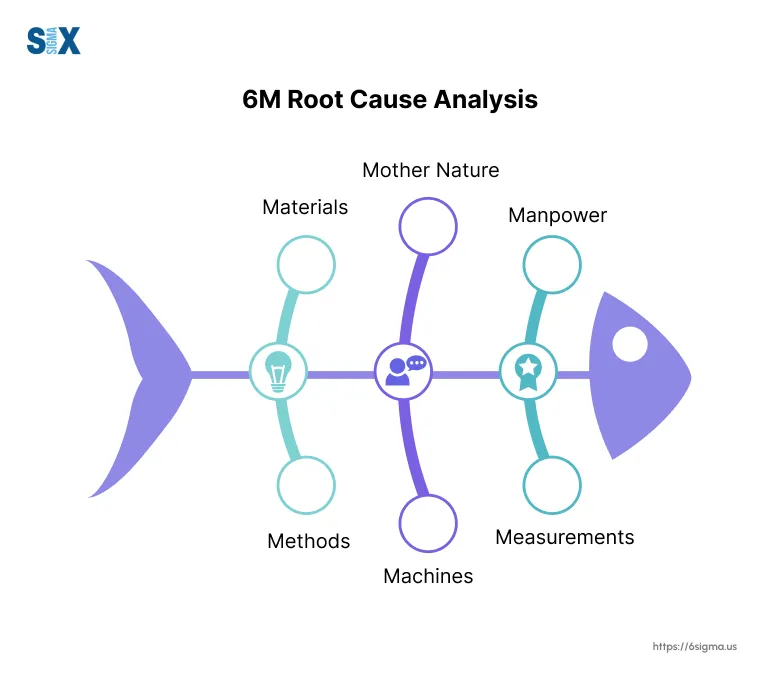

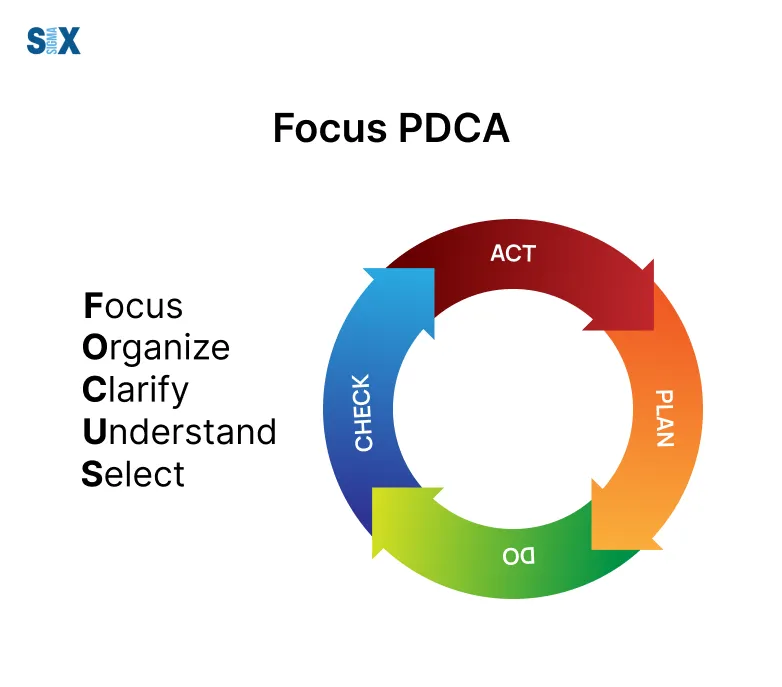

Root Cause Analysis and the PDCA Cycle

When issues arise in the scheduling process, root cause analysis techniques like the 5 Whys or Fishbone Diagrams can be used to identify the underlying causes.

The Plan-Do-Check-Act (PDCA) cycle, a cornerstone of continuous improvement, can be applied to systematically improve the scheduling process:

- Plan: Identify opportunities for improvement

- Do: Implement changes on a small scale

- Check: Measure the results of the changes

- Act: Standardize successful changes and start the cycle again

Capacity Planning and Waste Reduction Strategies

Effective capacity planning is crucial. It involves:

- Accurately estimating resource capacity

- Matching capacity to demand

- Identifying and addressing capacity constraints

Waste reduction strategies, based on the lean concept of the 8 Wastes (Defects, Overproduction, Waiting, Non-utilized talent, Transportation, Inventory, Motion, Extra-processing), can be applied to improve scheduling efficiency.

Benchmarking and Continuous Process Improvement (CPI)

Benchmarking against industry best practices and high-performing projects can provide valuable insights for improvement. Continuous process improvement involves:

- Regular review of scheduling processes

- Soliciting feedback from team members and stakeholders

- Implementing and measuring the impact of improvements

- Standardizing successful changes

Overcoming Challenges in Lean Scheduling Implementation

Implementing this often faces resistance.

Common challenges include:

- Cultural resistance to change

- Lack of understanding of lean principles

- Difficulty in quantifying benefits

- Inadequate leadership support

- Resistance to increased transparency

Strategies for Successful Adoption and Buy-in

Based on my experience leading Six Sigma deployments, successful adoption strategies include:

- Clear communication of benefits

- Leadership commitment and visible support

- Pilot projects to demonstrate value

- Celebrating early wins

- Involving team members in the implementation process

Training and Skill Development for Team Members

Effective training is crucial for successful implementation. This includes:

- Lean principles and tools

- Specific techniques

- Soft skills like communication and problem-solving

- Continuous learning and improvement mindset

Balancing Flexibility With Structure in Scheduling

While it promotes flexibility, it’s important to maintain some structure. This balance can be achieved through:

- Clear project goals and milestones

- Regular check-ins and adjustments

- Standardized processes for routine tasks

- Flexibility in addressing unexpected challenges

Future Trends and Innovations in Lean Scheduling

The future of lean scheduling is closely tied to technological advancements. Emerging trends include:

- AI-powered scheduling optimization

- Internet of Things (IoT) for real-time tracking

- Virtual and Augmented Reality for visualization

- Blockchain for improved traceability

AI and machine learning in lean scheduling

AI and machine learning are set to revolutionize lean scheduling. Potential applications include:

- Predictive analytics for resource allocation

- Automated constraint identification

- Intelligent task prioritization

- Adaptive scheduling based on real-time data

Integration with other project management methodologies

The future will likely see increased integration of lean scheduling with other methodologies like:

- Agile and Scrum

- Critical Chain Project Management

- Theory of Constraints

- Design Thinking

Sustainable practices

Sustainability is becoming increasingly important in project management. Lean scheduling can contribute to sustainability through:

- Reduced waste and resource consumption

- Improved energy efficiency in processes

- Optimized logistics and transportation

- Focus on long-term value creation

In conclusion, lean scheduling represents a powerful approach to project management that can lead to significant improvements.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs