Maximize Productivity and Improve Value Delivery with Kanban Planning

Managing projects well is key to success today. Traditional methods struggle to keep up with changing needs and markets. Kanban planning from lean ideas emerged as a smart solution.

Kanban focuses on visualizing the whole workflow, limiting simultaneous efforts, and measuring times. This optimizes how teams work. Central to Kanban is the Kanban board visually tracking items’ passage through stages.

Key Highlights

- Kanban planning uses a visual, continuous approach to managing projects in a lean, agile way.

- It applies a Kanban board that visually tracks work items as they move from step to step. It sets limits on simultaneous tasks too.

- Kanban focuses on just-in-time delivery, removing waste, and always upgrading workflows.

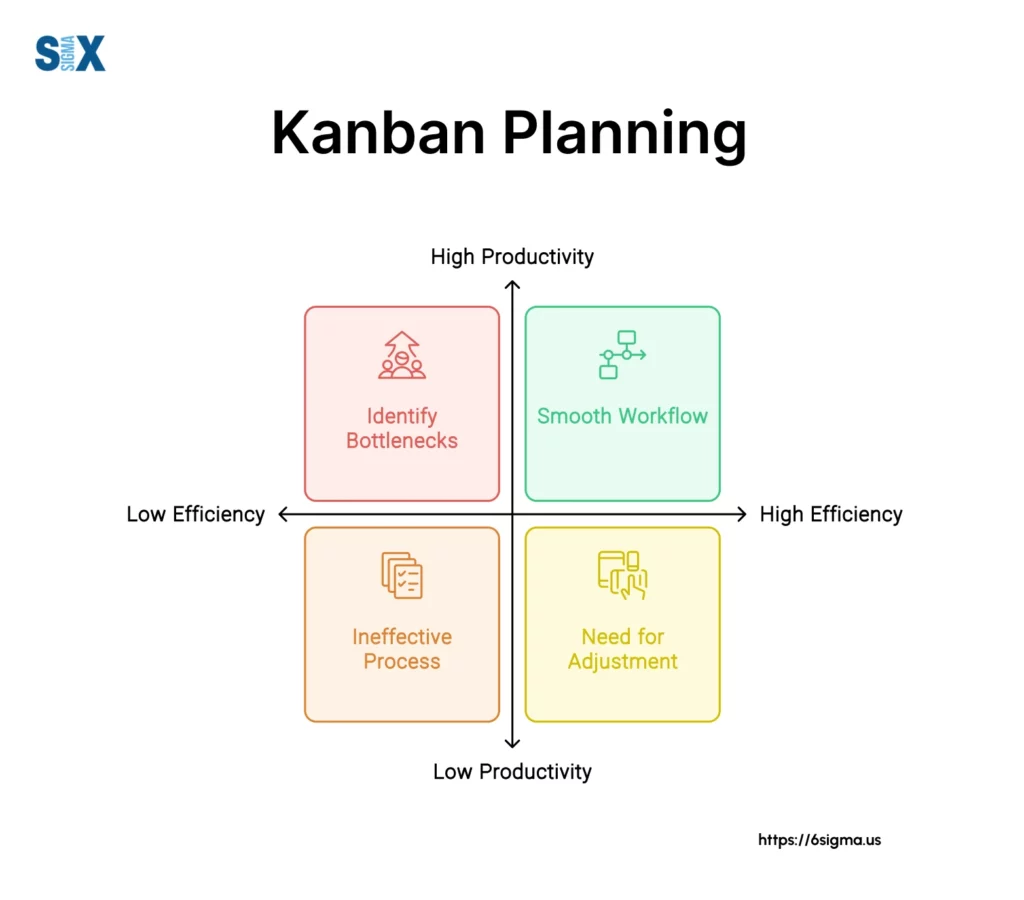

- Teams optimize how they operate, spot blocked areas, and shorten times/maximize output.

- Kanban integrates smoothly with Scrum and other agile methods for more powerful project guidance.

What is Kanban planning?

Kanban is a tool that helps break down large projects into smaller tasks, making them more manageable. By using a Kanban board, individuals can stay focused and ensure they are working on the right tasks. Kanban planning allows for a big picture view while ensuring all tasks are completed.

Kanban offers a lean way to manage and better all kinds of “thinking work” like development teams. Originally for programming, it now optimizes many creative undertakings.

Its core involves detailing the work, keeping task pile-ups in check, and gathering insights to refine endlessly.

The name takes from “visual signal” in Japanese, like cards Kanban uses in production to pace operations.

In knowledge work, Kanban displays undertakings virtually through boards/cards illustrating progress through a process. This brings transparency exposing upgradeable areas.

Unlike rigid project methodologies, Kanban strengthens gradually from the present operation. It refines incrementally what’s done now. This fits organizations exploring flexibility progressively.

Kanban’s goals center on visualizing workflows, capping efforts underway, measuring adeptness, and motivating relentless betterment through empirical data. It presents a tested ally navigating unpredictable climates optimally.

Principles of Kanban Planning

At its core, Kanban planning revolves around a few key principles that help teams visualize their workflow, maximize efficiency, and deliver value continuously. These guiding principles are:

Visualize the Workflow

One of the foundational principles of Kanban is to make the work visible. This is achieved by using a Kanban board, which is a visual representation of the team’s work items and their progression through various stages or states.

By visualizing the workflow, teams can identify bottlenecks, prioritize tasks, and optimize the flow of work.

Limit Work in Progress (WIP)

Kanban planning emphasizes the importance of limiting the amount of work in progress at any given time. By setting WIP limits, teams can prevent overburdening themselves with too many tasks, which can lead to context switching, reduced focus, and decreased productivity.

WIP limits help teams concentrate on completing tasks before taking on new work, ensuring a smooth and efficient workflow.

Manage Flow with Kanban Planning

Kanban planning is all about optimizing the flow of work through the system. Teams should strive to minimize lead times (the time it takes for a work item to travel from the initial request to final delivery) and cycle times (the time it takes for a work item to complete once it’s in progress).

By managing the flow effectively, teams can identify and address bottlenecks, reduce waste, and improve overall throughput.

Continuous Improvement (Kaizen)

Kanban planning encourages teams to continuously seek opportunities for improvement. Through regular retrospectives and data analysis, teams can identify areas for optimization, implement changes, and measure their impact.

This cyclical process of continuous improvement, known as Kaizen, helps teams refine their processes and adapt to changing circumstances.

Collaborative Approach with Kanban Planning

Kanban planning thrives on cross-functional collaboration and shared ownership of the workflow. Team members from different disciplines work together to understand the end-to-end process, identify dependencies, and collectively contribute to improving the system.

This collaborative approach fosters transparency, knowledge sharing, and a sense of collective responsibility.

Setting up a Kanban Board

A key aspect of kanban planning is creating a visual kanban board to manage your workflow. The kanban board serves as the central hub for visualizing work in progress, identifying bottlenecks, and optimizing your processes.

At its core, a kanban board is comprised of several columns that represent the different stages of your workflow or value stream. Common column names include “To Do”, “In Progress”, and “Done”, but you can customize these to fit your specific process.

When setting up your kanban board, it’s important to define clear “Definition of Done” criteria for each stage. This ensures everyone on the team understands what needs to be accomplished before work can move to the next column.

Implementing WIP Limits

A key kanban practice is establishing work-in-progress (WIP) limits for each workflow stage. WIP limits prevent overloading any given step and promote a smooth, continuous flow of work. Typical WIP limits are represented visually on the kanban board by maximum slots or swim lanes.

By capping how much-unfinished work is in progress, kanban planning helps surface bottlenecks and exposes opportunities for process improvements. WIP limits are often adjusted through trial and error based on observed cycle times and throughput metrics.

Configuring Swim Lanes for Kanban Planning

Many Kanban boards utilize horizontal swim lanes to represent different work streams, priorities, or cross-functional teams. Swim lanes provide additional visual structure and allow you to practice WIP limits at more granular levels.

For example, you could have separate lanes for customer-driven work versus internal projects. Or you could use lanes to separate work assigned to different developers or squads. Using swim lanes judiciously can boost transparency and balance across multiple workflows.

Kanban Board Tools

While physical kanban boards with sticky notes are still used, most teams today opt for digital kanban solutions like Trello, Jira, or custom kanban software. These tools make it easy to create flexible board layouts, assign work items, track cycle times, and integrate with other systems.

When selecting a Kanban tool, consider its ability to visualize your workflow stages, implement WIP limits, support swim lanes, generate reports, and integrate with other applications in your toolchain.

Kanban Planning in Practice

Implementing kanban planning in your organization requires more than just setting up a kanban board.

It involves a shift in mindset and culture towards visualizing work, limiting work-in-progress, and focusing on flow efficiency. Here are some practical steps to get started with kanban planning:

Identify Value Streams

Begin by mapping out your value streams, which represent the sequence of steps required to deliver value to your customers.

This could be a product development process, a service delivery workflow, or any other critical business process. Understand the steps involved and identify potential bottlenecks or areas of waste.

Design Your Kanban System

Based on your value streams, design a kanban system that visually represents the flow of work. This typically involves creating a kanban board with columns representing the different stages of your process.

Define explicit policies for work-in-progress (WIP) limits, how work items move between columns, and any other rules to govern your kanban system.

Establish WIP Limits with Kanban Planning

One of the core principles of kanban is limiting the amount of work in progress at any given time. By capping the number of work items in each column or stage of your process, you reduce context-switching and increase focus.

Determine appropriate WIP limits based on your team’s capacity and the nature of the work.

Prioritize the Backlog

With a visual representation of your workflow, you can prioritize your backlog of work items more effectively.

Use techniques like cost of delay analysis or weighted shortest job first to ensure you’re always working on the highest-value items first.

Conduct Daily Standups for Kanban Planning

Kanban planning emphasizes regular communication and collaboration. Daily standup meetings provide an opportunity for team members to sync up, discuss bottlenecks, and identify potential improvements to the process.

Measure and Optimize Flow with Kanban Planning

Kanban planning heavily relies on metrics and data to drive continuous improvement. Track metrics like cycle time, lead time, and throughput to identify bottlenecks and areas for optimization.

Use tools like cumulative flow diagrams and control charts to visualize and analyze your process performance over time.

Foster a Culture of Continuous Improvement

Kanban planning is not a one-time implementation but an ongoing journey of continuous improvement.

Encourage a culture of kaizen, where team members are empowered to identify and eliminate waste, streamline processes, and continuously improve the way work flows through your organization.

Metrics and Measurements

One of the key benefits of Kanban planning is the ability to measure and optimize your workflow through data-driven metrics. By tracking the right metrics, you can identify bottlenecks, improve processes, and increase overall efficiency. Here are some important Kanban metrics to monitor:

Cycle Time

Cycle time measures the total time it takes for a work item to travel through your workflow, from the moment it is pulled into the “Doing” state until it reaches the “Done” state. Monitoring cycle times allows you to set reasonable expectations and deadlines.

Lead Time

Lead time is the total time from when a work item is initially requested until it is finally delivered to the customer. Optimizing lead times ensures you are providing value to customers as quickly as possible.

Work in Progress (WIP) Limits and Kanban Planning

WIP limits are the maximum number of work items allowed in each workflow state at one time. Enforcing WIP limits prevents overloading team members and allows work to flow smoothly.

Throughput

Throughput tracks the number of work items completed per period (day, week, month, etc.). Increasing throughput means delivering more value in less time.

Cumulative Flow Diagrams and Kanban Planning

These visualize your workflow states and track how work items traverse the system over time. They help identify bottlenecks and process improvement opportunities.

In addition to flow metrics, kanban planning encourages tracking other lean metrics like:

- Percent value-added time

- Defect rates

- Resource utilization rates

Continuous Improvement with Kanban

One of the core principles of kanban planning is the idea of continuous improvement, also known as kaizen. The Kanban system provides a visual workflow that makes it easy to identify opportunities for optimization and process improvements.

By monitoring metrics like cycle time, lead time, and throughput, teams can pinpoint bottlenecks and areas of waste or inefficiency.

A key practice for driving continuous improvement is to regularly review the Kanban board and analyze the flow of work.

During these review sessions, teams should look for any stuck or blocked work items and determine the root causes. They can then devise countermeasures to prevent similar issues from reoccurring, a technique called root cause analysis.

Another powerful mechanism is to use data from cumulative flow diagrams and cycle time scatterplots to identify process constraints and variability.

Teams can run experiments to smooth flow, such as adjusting work-in-progress (WIP) limits, swarming items, or implementing quality policies at specific points.

The daily standup meeting, a common agile ceremony, also enables continuous improvement within Kanban. Each day, team members can raise impediments or blockers they are facing. The team can then swarm to remove those impediments on time.

Ultimately, continuous improvement should become an ingrained habit for Kanban teams. Cultivating a mindset of embracing change and seeking ways to optimize flow is crucial.

Techniques like value stream mapping can provide a higher-level view to discover improvement opportunities across multiple processes.

Integrating Kanban with Other Methodologies

While kanban is a powerful methodology on its own, many teams find value in combining it with other agile and lean approaches. This allows them to capitalize on the strengths of multiple frameworks while addressing any limitations or gaps.

Kanban Planning and Scrum

One popular combination is using kanban alongside scrum.

The iterative sprint cycles of scrum can provide structure and cadences, while the Kanban board and WIP limits help visualize and optimize flow. Some teams practice scrumban, which blends the practices in a more formalized way.

Kanban and Lean/Six Sigma

Kanban’s roots are in lean manufacturing principles like reducing waste, optimizing value streams, and continuous improvement.

Teams practicing lean or Six Sigma methodologies often adopt Kanban as a powerful visualization and flow management tool. Value stream mapping pairs well with mapping your workflow across a Kanban board.

Kanban and SAFe

The Scaled Agile Framework (SAFe) provides a way to scale lean-agile practices to an enterprise level.

The portfolio and program Kanban systems in SAFe allow organizations to visualize and manage the flow of epics and larger initiatives across teams and departments using Kanban principles.

Kanban Planning and DevOps

The practices of Kanban planning, visualization, WIP limits, and flow metrics align well with DevOps principles like continuous integration, continuous delivery, and site reliability engineering. Kanban boards can map value streams across the full software delivery lifecycle.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs