The Top 15 Process Improvement Tools: Boost Your Business Efficiency

Process improvement tools help businesses identify problems, streamline operations, and boost efficiency.

Each tool serves a specific purpose in making your operations better. From mapping out workflows to solving complex problems, these tools give you practical ways to enhance how your business runs.

What You’ll Learn in This Guide

- Detailed explanations of each tool

- Real examples of how businesses use these tools

- Step-by-step guides for implementation

- Tips to avoid common pitfalls

- Ways to measure success

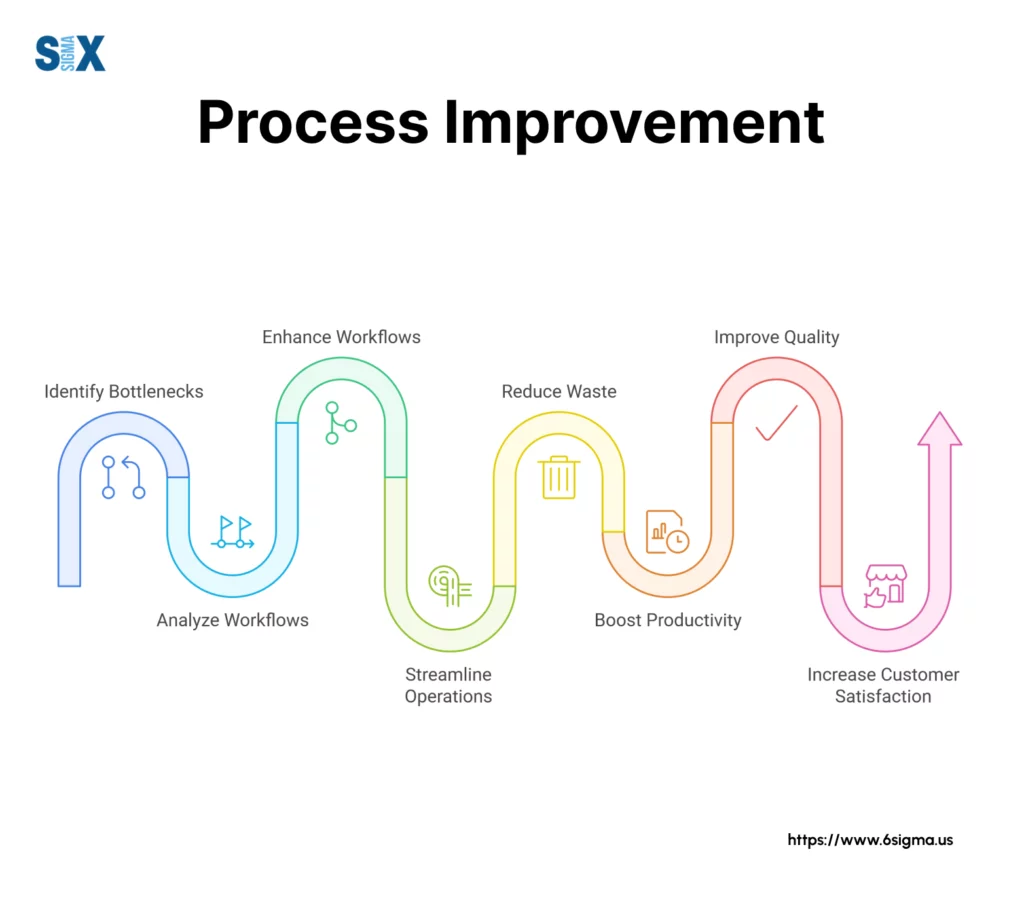

What Is Process Improvement?

Process improvement means making your business operations work better. It’s like fine-tuning an engine – you identify what’s slowing things down, fix the issues, and keep your business running smoothly.

Every business, from small startups to large corporations, can benefit from improving their processes.

Six Sigma certification focuses on mastering systematic methodologies where you can identify inefficiencies and driving measurable improvements.

Examples of Process Improvement

Let’s look at how process improvement works in practice:

- A restaurant cuts food prep time by reorganizing their kitchen layout

- An insurance company reduces claim processing from 5 days to 2 days

- A manufacturing plant decreases defects by 40% through better quality checks

Why Process Improvement Tools Matter

Process improvement tools give you a structured way to solve business problems.

They’re like a mechanic’s toolkit – each tool helps fix specific issues in your operations. Some tools help you map out workflows, while others help identify and solve problems.

Key Benefits You’ll See

When you use process improvement tools correctly, you’ll notice:

- Faster delivery times

- Lower operational costs

- Fewer mistakes and defects

- Happier employees

- More satisfied customers

- Better profit margins

Common Challenges You Might Face

Improving processes isn’t always easy. Here are the challenges most businesses face:

Employee Resistance

People often resist change. The key is involving your team early and showing them how improvements make their jobs easier.

Resource Constraints

You might not have endless time or money. Start small – focus on one process at a time and build momentum through quick wins.

Lack of Clear Goals

Without specific goals, improvement efforts can lose direction. Set clear, measurable targets like “reduce processing time by 25%” or “cut errors by half”.

Maintaining Improvements

Many businesses struggle to keep improvements going. Regular monitoring and team check-ins help sustain the gains you make.

Getting Past These Challenges

Here’s what successful companies do:

- Start with small, manageable projects

- Measure results to show progress

- Celebrate wins with their teams

- Make improvement part of daily work

- Keep communication channels open

Remember, process improvement isn’t a one-time project – it’s an ongoing journey.

The most successful businesses make it part of their culture and keep looking for ways to get better.

Transform your business operations with our Yellow Belt training

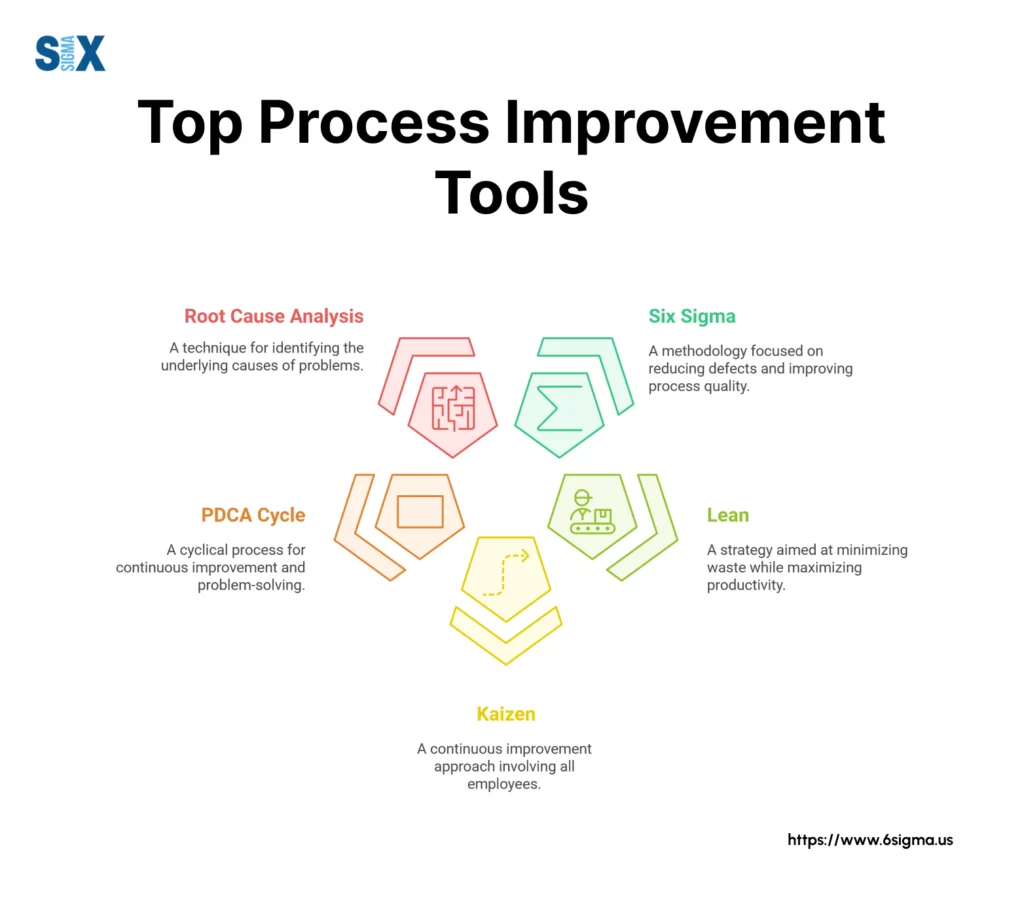

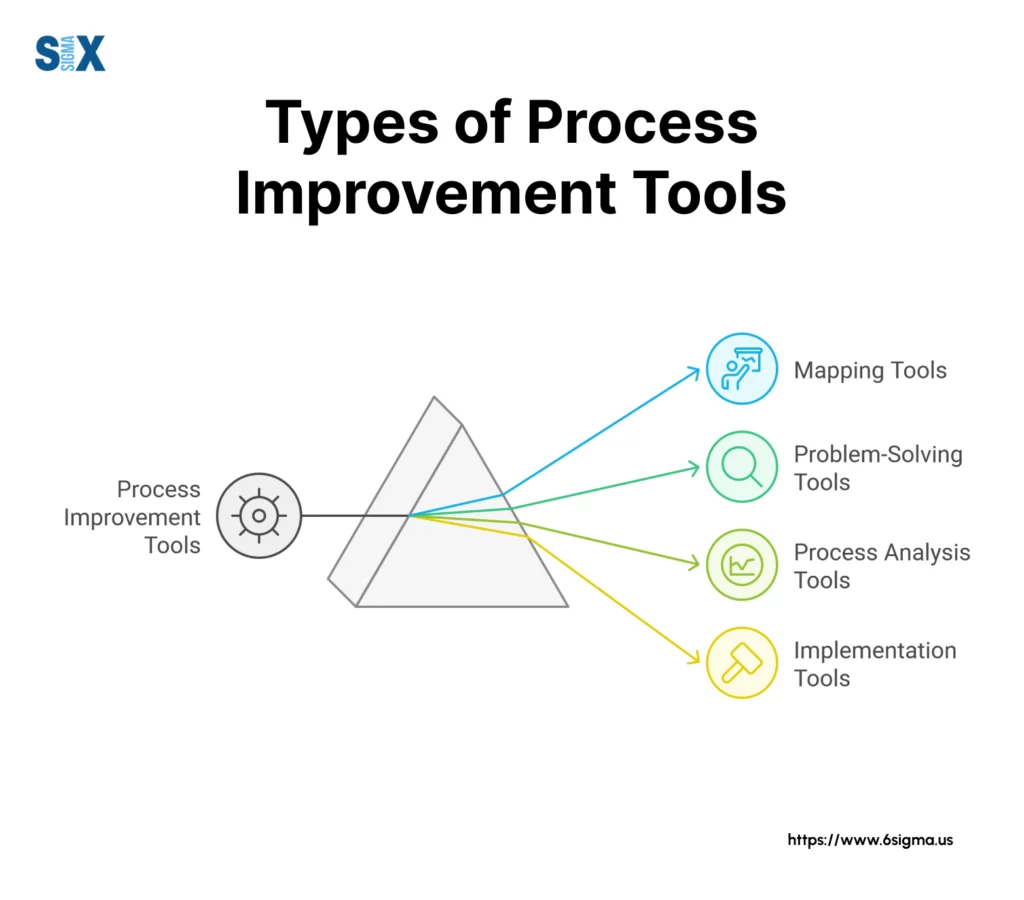

Types of Process Improvement Tools

Let’s break down process improvement tools into four main categories. Think of these categories like different departments in a hardware store – each section has specific tools for different jobs.

Mapping Tools: Visualize Your Processes

Mapping tools help you see how work flows through your business. They’re like creating a roadmap of your operations.

Popular mapping tools include:

- Value Stream Mapping: Shows how materials and information move through your business

- Process Flowcharts: Create step-by-step diagrams of your workflows

- SIPOC Diagrams: Map out suppliers, inputs, processes, outputs, and customers

When to use mapping tools:

- You need to understand complex workflows

- Teams aren’t clear about process steps

- You want to find bottlenecks in your operations

Problem-Solving Tools: Find and Fix Issues

These tools help you identify and solve specific problems in your processes.

Key problem-solving tools:

- 5 Whys Analysis: Dig deep to find root causes

- Fishbone Diagrams: Map out all possible causes of a problem

- Pareto Analysis: Focus on the vital few issues causing most problems

When to use problem-solving tools:

- Quality issues keep popping up

- You face recurring problems

- You need to prioritize which problems to tackle first

Process Analysis Tools: Measure and Improve

Analysis tools help you understand how well your processes work and where to improve them.

Popular analysis tools:

- Six Sigma: Reduce defects through data analysis

- Statistical Process Control: Monitor process performance

- Capability Analysis: Measure if processes meet requirements

When to use analysis tools:

- You need data to make decisions

- Quality standards aren’t being met

- You want to predict process performance

Organizations implementing Six Sigma often train teams through structured Six Sigma certification programs, which equip professionals with data-driven problem-solving frameworks like DMAIC.

Implementation Tools: Make Changes Stick

These tools help you put improvements in place and maintain them.

Key implementation tools:

- PDCA Cycle: Plan, Do, Check, Act for continuous improvement

- 5S: Organize workspaces for efficiency

- Kaizen Events: Make rapid improvements in specific areas

When to use implementation tools:

- You’re ready to make changes

- Teams need a structured way to improve

- You want to maintain gains over time

Choosing the Right Process Improvement Tools

Here’s a quick guide to picking the right tool:

- Start with mapping tools to understand your current process

- Use problem-solving tools to identify issues

- Apply analysis tools to measure and improve

- Use implementation tools to make changes and maintain them

How Process Improvement Tools Work Together

A manufacturing company I worked with used:

- Value Stream Mapping to visualize their production line

- 5 Whys to find the cause of delays

- Statistical Process Control to measure improvements

- PDCA to implement and maintain changes

Result: They cut production time by 40% and reduced defects by half.

Remember: You don’t need to use every tool. Pick the ones that fit your specific needs and start with the basics. As you get more comfortable, you can add more tools to your toolkit.

15 Most Effective Process Improvement Tools

Let’s explore the most powerful tools that can transform your business operations. I’ll share examples and practical tips for each tool based on my experience implementing them across different industries.

1. Six Sigma: Eliminate Defects and Variation

Six Sigma isn’t just a tool – it’s a complete methodology that helps you deliver near-perfect products and services.

The DMAIC Process

- Define: Identify the problem and goals

- Measure: Collect data about current performance

- Analyze: Find root causes of problems

- Improve: Implement and verify solutions

- Control: Maintain the improvements

Earning a Six Sigma Green Belt certification provides in-depth training on executing DMAIC, enabling practitioners to lead complex improvement projects.

Success Story

A medical device manufacturer used Six Sigma to tackle their quality issues.

They:

- Reduced defects by 40%

- Cut rework costs by $300,000 annually

- Improved customer satisfaction scores by 25%

2. Lean Manufacturing: Remove Waste

Toyota pioneered Lean manufacturing, and it’s now used worldwide to eliminate waste and improve efficiency.

Key Lean Tools

- 5S: Organize workspaces

- Kanban: Manage workflow

- Just-in-Time: Reduce inventory

- Value Stream Mapping: Visualize processes

Toyota’s Success Story

Toyota’s Lean approach helped them:

- Reduce inventory costs by 75%

- Cut production time by 50%

- Improve quality while lowering costs

To start with introductory Lean Fundamentals course often cover core tools like 5S and Value Stream Mapping, providing a foundation for waste reduction.

3. PDCA Cycle: Simple But Powerful

The Plan-Do-Check-Act cycle gives you a structured way to solve problems and improve processes.

How PDCA Works

- Plan: Set goals and predict outcomes

- Do: Test your solution on a small scale

- Check: Measure the results

- Act: Implement or adjust based on results

Practical Example

A restaurant used PDCA to improve their service time:

- Plan: Target 20-minute service time

- Do: Tested new kitchen layout

- Check: Measured actual service times

- Act: Rolled out new layout to all shifts

- Result: Cut average service time from 30 to 18 minutes

4. 5 Whys Analysis: Get to The Root Cause

The 5 Whys helps you dig deep to find the real cause of problems. It’s simple but incredibly effective.

How to Use 5 Whys

Start with your problem and keep asking “why” until you find the root cause. Here’s a real example:

Problem: Late deliveries

- Why are deliveries late? → Trucks leave the warehouse late

- Why do trucks leave late? → Loading takes too long

- Why does loading take too long? → Can’t find the right products

- Why can’t products be found? → Poor warehouse organization

- Why is the warehouse poorly organized? → No standard storage system

5. Value Stream Mapping: See The Whole Picture

Value Stream Mapping shows you exactly how work flows through your business. It’s like getting a bird’s eye view of your operations.

Creating Your Map

- Draw current state: Show how things work now

- Identify waste: Look for bottlenecks and delays

- Design future state: Map out improvements

- Create action plan: List specific changes needed

Success Story

An auto parts supplier mapped their process and found:

- 3 unnecessary handoffs

- 2 days of inventory sitting idle

- 40% reduction in lead time after improvements

6. Fishbone Diagram: Break Down Complex Problems

Also called the Ishikawa diagram, this tool helps you see all possible causes of a problem.

Main Components

- People: Staff-related issues

- Process: Workflow problems

- Equipment: Machine or tool issues

- Materials: Supply chain concerns

- Environment: Workplace factors

- Management: Leadership decisions

Healthcare Example

A hospital used this to reduce patient wait times:

- Found 23 potential causes

- Identified 3 major issues to fix first

- Cut wait times by 45%

7. Pareto Analysis: Focus On What Matters Most

The 80/20 rule helps you focus on the vital few issues causing most problems.

How It Works

- List all problems

- Measure their impact

- Rank from highest to lowest

- Focus on top 20% causing 80% of issues

Customer Service Example

A call center found:

- 3 issues caused 80% of complaints

- Fixed these first

- Reduced complaints by 60%

8. Process Flowcharts: Map Your Way To Success

Flowcharts give you a clear picture of how work should flow.

Types of Flowcharts

- Basic: Simple step-by-step

- Detailed: Including decisions points

- Swim lane: Shows who does what

- Cross-functional: Maps complex processes

Sales Process Example

A software company mapped their sales process:

- Found 5 unnecessary steps

- Cut sales cycle by 30%

- Improved close rate by 25%

9. Kaizen: Small Changes, Big Results

Kaizen means ‘continuous improvement‘ – making small changes every day.

Key Principles

- Everyone involved

- Daily improvements

- Focus on small wins

- Eliminate waste

Success Story

A manufacturing plant used Kaizen to:

- Reduce setup time by 20%

- Cut defects by 30%

- Boost productivity by 25%

10. Statistical Process Control (SPC): Data-Driven Decisions

SPC helps you monitor and control processes using statistical data. It’s like having a dashboard for your operations.

Key Features

- Control charts

- Process capability studies

- Variation analysis

- Trend monitoring

Manufacturing Example

A food processor used SPC to:

- Reduce product weight variation by 50%

- Save $200,000 in material costs

- Improve product consistency

11. Gemba Walk: See It For Yourself

Gemba means “the real place” – where work actually happens.

How to Do It Right

- Go to the workplace

- Observe actual work

- Talk to employees

- Look for improvement opportunities

Retail Success Story

A store manager’s Gemba walks revealed:

- Inefficient storage layout

- Unnecessary walking distances

- After changes: 30% faster restocking

12. SIPOC Diagram: Map Your Process Chain

SIPOC helps you see how your process connects with suppliers and customers.

Components

- Suppliers: Who provides inputs?

- Inputs: What goes into the process?

- Process: What happens?

- Outputs: What’s produced?

- Customers: Who receives the output?

Service Industry Example

An insurance company used SIPOC to:

- Identify missing process steps

- Reduce claim processing time by 40%

- Improve customer satisfaction

13. Root Cause Analysis (RCA): Solve Problems Permanently

RCA helps you find and fix the true source of problems.

Key Steps

- Define the problem

- Collect data

- Identify causes

- Find root cause

- Implement solutions

IT Case Study

A tech company used RCA to:

- Solve recurring server crashes

- Prevent 90% of downtime

- Save $500,000 annually

Formal root cause analysis training teach structured techniques like the 5 Whys and Fishbone Diagrams to systematically address recurring issues.

14. Bench-marking: Learn From The Best

Compare your processes with industry leaders to find improvement opportunities.

Types of Benchmarking

- Internal: Compare between departments

- Competitive: Study competitors

- Industry: Look at similar businesses

- Best-in-class: Learn from top performers

Healthcare Example

A hospital bench-marked patient discharge:

- Found 40% faster processes elsewhere

- Adopted best practices

- Reduced discharge time by 35%

15. Theory of Constraints (TOC): Remove Bottlenecks

TOC helps you identify and fix what’s holding your process back.

Core Principles

- Find the constraint

- Exploit the constraint

- Subordinate everything else

- Elevate the constraint

- Repeat the process

Project Management Success

A construction company used TOC to:

- Identify critical path bottlenecks

- Reduce project delays by 60%

- Improve resource allocation

Choosing The Right Tool

Pick your tool based on your goal:

- Quality issues? Start with Six Sigma

- Efficiency problems? Try Lean

- Unknown issues? Use 5 Whys or RCA

- Complex processes? Begin with Value Stream Mapping

These tools work best when combined thoughtfully. Start with one, master it, then add others as needed.

How to Choose The Right Process Improvement Tool

Picking the right tool makes all the difference in your improvement efforts. Here’s how to make the best choice for your situation.

Key Factors to Consider when Selecting a Process Improvement Tool

Before selecting a tool, ask yourself:

- What problem are you trying to solve?

- How complex is your process?

- What resources do you have?

- How much time can you invest?

- What’s your team’s experience level?

Matching Tools to Business Problems

Quality Issues:

- Six Sigma for reducing defects

- SPC for monitoring quality

- Fishbone diagrams for finding causes

Efficiency Problems:

- Lean Manufacturing for removing waste

- Value Stream Mapping for process flow

- Theory of Constraints for bottlenecks

Unknown Problems:

- 5 Whys for root causes

- Gemba Walks for direct observation

- SIPOC for process overview

Drive game-changing improvements with our Black Belt training in advanced process optimization techniques

Making Process Improvements Stick

Start Small

- Pick one process

- Set clear goals

- Get quick wins

Build Your Team

- Train key people

- Assign clear roles

- Create accountability

Track Progress

- Measure results

- Document changes

- Share successes

Watch Out For These Pitfalls

- Trying too much too soon

- Not involving front-line staff

- Skipping the training step

- Forgetting to measure results

- Losing momentum after initial success

Keys to Long-Term Success

Make it routine

- Regular check-ins

- Monthly reviews

- Ongoing training

Celebrate wins

- Share success stories

- Recognize team efforts

- Build on momentum

Keep improving

- Set new goals

- Try new tools

- Learn from setbacks

Next Steps: Getting Started with your Process Improvement Tool

Ready to improve your processes? Here’s what to do:

- Pick your biggest pain point

- Choose one tool that fits

- Start small and measure results

- Build on your success

Process improvement isn’t a one-time project – it’s a journey. Start where you are, use what you have, and keep moving forward.

Your Action Plan

This week:

- Identify one process to improve

- Pick a suitable tool

- Get your team on board

Next month:

- Implement your first improvement

- Measure the results

- Share the success

Long term:

- Build your toolkit

- Train your team

- Create a culture of improvement

The most successful businesses make process improvement part of their DNA. You’ve got the tools – now it’s time to put them to work.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs