Process Characterization: A Guide for Pharmaceutical and Biotech Industries

Over the time the biotech and pharmaceutical industries have significantly developed their manufacturing process.

Process characterization serves as the cornerstone of modern drug development and production, enabling manufacturers to maintain consistent quality while optimizing operational efficiency.

Global pharmaceutical manufacturing sector reached $405.52 billion in 2023, with process characterization playing a vital role in this growth.

Key Highlights

- Fundamental aspects of process characterization

- Implementation across various pharmaceutical manufacturing scenarios

- Detail specific methodologies

- Regulatory requirements

- Technological innovations

- Define modern process characterization practices

What is Process Characterization?

Process characterization represents a systematic methodology for identifying and quantifying critical process parameters that affect product quality in pharmaceutical manufacturing.

This scientific approach enables manufacturers to establish consistent production methods while meeting regulatory requirements.

The FDA and EMA guidelines emphasize process characterization as a crucial step in ensuring product safety and efficacy.

Manufacturing facilities utilize process characterization to map the relationships between input variables and output qualities.

This mapping creates a documented understanding of how different parameters influence product attributes, allowing for precise control and optimization of manufacturing processes.

The Characterization Process Framework

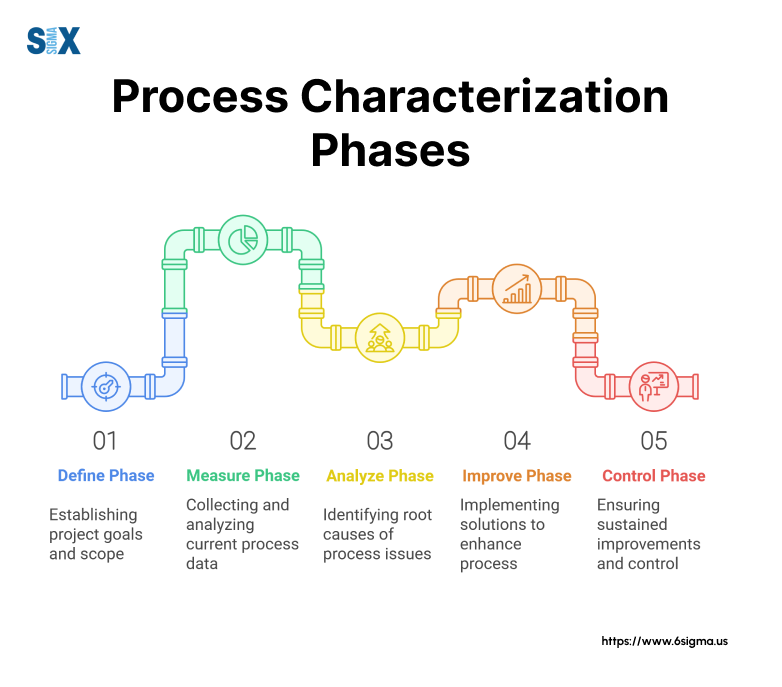

The characterization process follows a structured sequence of activities:

Phase 1: Parameter Identification

- Evaluation of critical process parameters (CPPs)

- Assessment of key performance indicators (KPIs)

- Documentation of control requirements

Phase 2: Risk Analysis

- Implementation of failure mode and effects analysis (FMEA)

- Determination of critical quality attributes (CQAs)

- Establishment of risk mitigation strategies

Phase 3: Data Collection and Analysis

- Design of experiments (DoE)

- Statistical process control implementation

- Performance monitoring systems setup

Purpose and Strategic Objectives

Process characterization serves multiple strategic objectives in pharmaceutical manufacturing. It enables manufacturers to:

- Establish validated production parameters

- Maintain consistent product quality

- Reduce batch-to-batch variability

- Meet regulatory compliance requirements

- Optimize manufacturing efficiency

Statistical data shows that effective process characterization reduces manufacturing deviations and increases batch success rates.

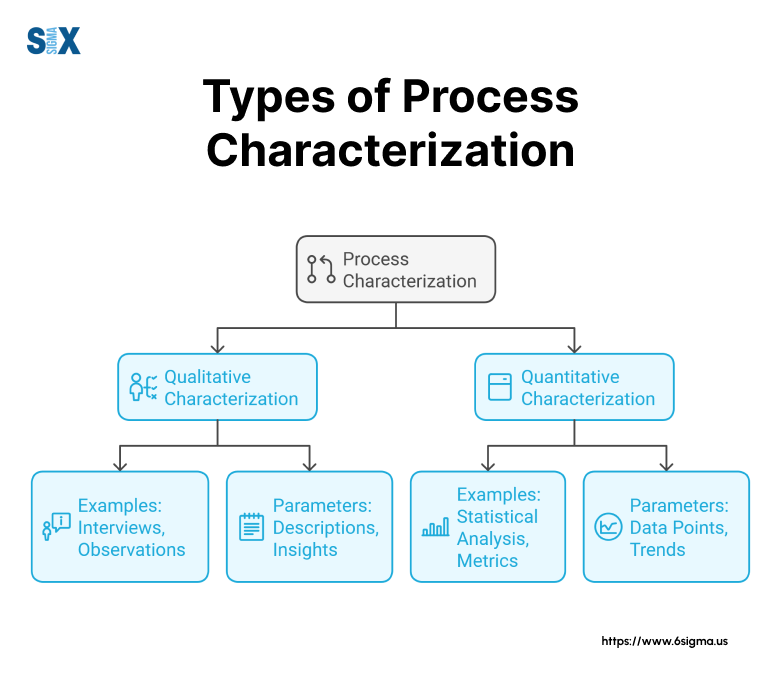

Types of Process Characterization

Modern pharmaceutical manufacturing employs several types of process characterization:

Chemical Characterization

- Focuses on molecular structure analysis

- Determines chemical composition stability

- Evaluates impurity profiles

Physical Characterization

- Examines material properties

- Analyzes particle size distribution

- Measures flow characteristics

Biological Characterization

- Assesses protein structure

- Evaluates biological activity

- Determines potency measurements

Process Characteristics in Practice

Manufacturing facilities must monitor specific process characteristics:

Temperature Control Parameters

Temperature variations can significantly impact product quality. Manufacturers typically maintain temperature controls within ±0.5°C during critical process steps.

pH Monitoring Systems

Precise pH control, often requiring accuracy within ±0.1 units, ensures consistent product quality across batches.

Pressure Management

Pressure parameters influence filtration and separation processes, requiring monitoring within specified ranges, typically ±5 psi.

Time Management

Critical process steps often require strict timing controls, with allowable deviations of less than ±5% from established parameters.

These characteristics form the foundation of process control strategies, enabling manufacturers to maintain consistent product quality while optimizing production efficiency.

This systematic approach to process characterization provides pharmaceutical manufacturers with the tools needed to maintain product quality while meeting regulatory requirements.

The integration of modern monitoring systems and data analysis tools continues to enhance the effectiveness of process characterization methods.

Regulatory Requirements for Process Characterization

The Food and Drug Administration (FDA) established specific guidelines for process characterization through its 2011 Process Validation Guidance document.

These guidelines mandate manufacturers to demonstrate thorough process understanding through scientific evidence. The FDA requirements focus on three critical aspects:

Quality by Design (QbD) Implementation

Manufacturers must incorporate QbD principles into their process characterization activities. This includes establishing design space parameters and implementing control strategies based on scientific rationale.

Statistical Analysis Requirements

FDA guidelines specify the need for robust statistical methods in process characterization.

Manufacturers must employ appropriate sampling plans and statistical tools to validate process parameters, with a minimum confidence level of 95%.

Documentation Standards

The agency requires detailed documentation of process characterization studies, including raw data, statistical analyses, and justification for parameter ranges.

These records must demonstrate the scientific basis for process control decisions.

EMA Standards and Protocols

The European Medicines Agency (EMA) maintains distinct requirements for process characterization, emphasizing several key areas:

Process Understanding

EMA guidelines require manufacturers to demonstrate detailed understanding of their processes through systematic characterization studies.

This includes identifying critical process parameters (CPPs) and their relationships to critical quality attributes (CQAs).

Risk Management Integration

Manufacturers must integrate risk assessment methodologies into their process characterization activities.

The EMA specifically requires:

- Documented risk assessment procedures

- Regular risk review protocols

- Risk-based decision-making evidence

Validation Requirements

The agency mandates continuous process verification alongside traditional validation approaches. This requires ongoing monitoring and analysis of process performance indicators.

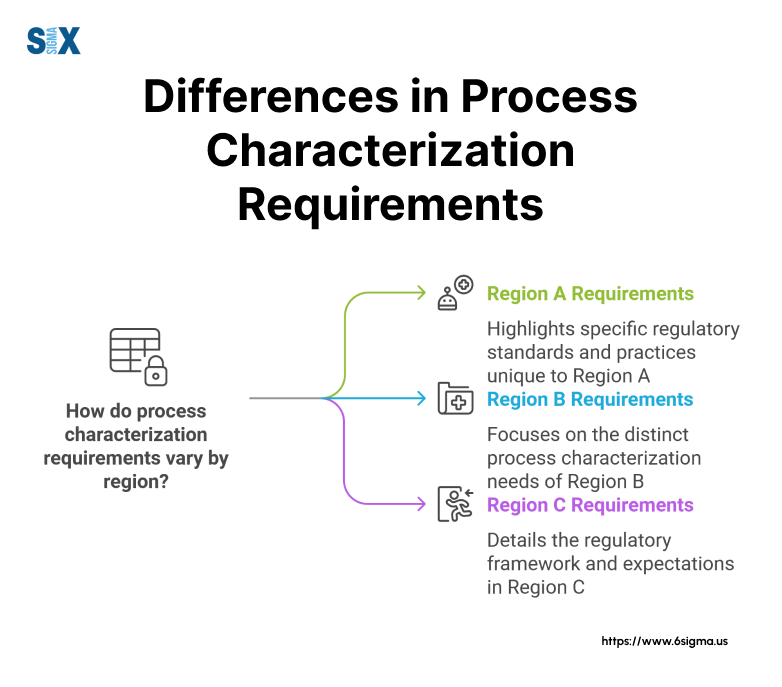

Global Regulatory Variations of Process Characterization

Different regions maintain varying requirements for process characterization:

Asia-Pacific Requirements

Japanese PMDA guidelines emphasize:

- Enhanced focus on raw material characterization

- Stricter stability testing requirements

- More detailed process flow documentation

Chinese NMPA standards require:

- Additional in-process testing

- Extended stability studies

- Local validation requirements

ICH Guidelines Integration

The International Council for Harmonisation (ICH) provides harmonized guidelines that influence global requirements:

Q8 Pharmaceutical Development

Establishes foundational requirements for process characterization within pharmaceutical development.

Q9 Quality Risk Management

Defines risk assessment frameworks essential for process characterization activities.

Q10 Pharmaceutical Quality System

Outlines quality system requirements that support effective process characterization.

Regulatory Compliance Strategies

Modern pharmaceutical manufacturers must implement strategies to meet these varied requirements:

Digital Compliance Systems

Implementation of electronic systems for:

- Real-time data collection

- Automated documentation

- Trend analysis capabilities

Quality Management Integration

Development of integrated quality systems that address:

- Multiple regulatory requirements

- Regional variations

- Global compliance standards

The evolution of regulatory requirements continues to shape process characterization methodologies.

Manufacturers must maintain awareness of these changing requirements while implementing systems that ensure consistent compliance across global markets.

Step-by-Step Implementation for Process Characterization

The implementation of process characterization requires meticulous planning to ensure successful outcomes.

Manufacturing facilities must establish clear objectives, timelines, and resource allocation strategies. The planning phase typically spans 3-6 months, depending on process complexity.

Key Planning Elements:

- Resource identification and allocation

- Timeline development with critical milestones

- Budget establishment and approval

- Team formation and responsibility assignment

- Documentation system setup

Risk Assessment Methodologies

Risk assessment forms the foundation of effective process characterization. Modern pharmaceutical facilities employ structured approaches to identify and evaluate potential risks:

FMEA Implementation

Failure Mode and Effects Analysis helps identify critical process parameters. Teams evaluate severity, occurrence, and detection ratings for each potential failure mode.

Risk Prioritization Matrix

Manufacturing teams develop risk matrices considering:

- Process impact levels

- Detection probability

- Occurrence frequency

- Mitigation feasibility

Data Collection Protocols in Process Characterization

Systematic data collection ensures reliable process characterization results. Manufacturing facilities must implement robust data collection systems:

Automated Data Collection

Modern facilities utilize automated systems capturing:

- Real-time process parameters

- Quality measurements

- Environmental conditions

- Equipment performance metrics

Manual Data Recording

Specific parameters requiring human observation include:

- Visual inspections

- Qualitative assessments

- Operator observations

- Equipment status checks

Statistical Analysis Methods

Process characterization six sigma methodologies provide structured approaches to data analysis. Statistical techniques employed include:

Design of Experiments (DoE)

- Factorial designs for parameter interaction studies

- Response surface methodology for optimization

- Screening designs for parameter significance

Statistical Process Control (SPC)

Manufacturing facilities implement SPC tools:

- Control charts for process monitoring

- Capability analysis for process evaluation

- Trend analysis for pattern detection

- Variance analysis for parameter impact

Master statistical process control with Six Sigma Champion – Leadership Program

Results Interpretation Framework

Data interpretation requires structured approaches to ensure accurate conclusions:

Quantitative Analysis

- Statistical significance evaluation

- Process capability determination

- Parameter interaction assessment

- Trend identification and analysis

Qualitative Assessment

Teams evaluate:

- Process robustness indicators

- Operating parameter ranges

- Control strategy effectiveness

- Quality impact measurements

Implementation Strategy Development with Process Characterization

The final phase involves translating findings into actionable procedures:

Control Strategy Development

Teams establish:

- Operating parameter ranges

- Monitoring requirements

- Control limits

- Response protocols

Documentation Requirements

Manufacturing facilities must maintain:

- Standard operating procedures

- Process control documents

- Training materials

- Quality control protocols

Process characterization implementation requires continuous monitoring and adjustment.

Manufacturing facilities should review and update their characterization strategies annually or when significant process changes occur.

This ensures maintained alignment with current regulatory requirements and industry best practices.

Reduce Process Variations and Improve Quality Metrics.

Learn proven Six Sigma tools and tactics from industry experts with hands-on implementation experience.

Process Characterization and Optimization

Process characterization and optimization work synergistically to enhance manufacturing efficiency.

Statistical analysis of process data reveals optimization opportunities through several key indicators:

Performance Metrics Analysis

- Yield variations across batches

- Processing time deviations

- Resource utilization rates

- Quality attribute trends

Cost Impact Evaluation

- Production cost analysis

- Resource allocation efficiency

- Equipment utilization rates

- Energy consumption patterns

Implementation of Process Improvements

The implementation of identified improvements follows structured methodologies:

Parameter Adjustment Protocols

- Modified operating ranges

- Updated control limits

- Revised monitoring frequencies

- Enhanced control strategies

Technology Integration

- Real-time monitoring systems

- Automated control mechanisms

- Predictive maintenance protocols

- Data analytics platforms

Impact Measurement Systems

Quantitative assessment of optimization efforts requires robust measurement systems:

Performance Indicators

- Product quality improvements

- Cycle time reductions

- Yield increases

- Cost savings

ROI Analysis

- Cost reduction measurements

- Efficiency gain calculations

- Quality improvement values

- Resource optimization metrics

Process Characterization and Validation Integration

Process characterization directly supports validation efforts through:

Data Foundation

- Parameter relationships

- Operating ranges

- Control requirements

- Quality impacts

Risk Management

- Critical parameter identification

- Control strategy development

- Monitoring requirements

- Response protocols

Validation Support Through Process Characterization

Process characterization strengthens validation activities by:

Scientific Evidence Characterization data provides:

- Parameter impact evidence

- Process capability proof

- Control strategy justification

- Quality assurance documentation

Regulatory Compliance Characterization supports:

- Validation protocols

- Registration requirements

- Regulatory submissions

- Quality systems

Validation Strategy Development

Effective validation strategies build upon characterization results:

Protocol Development

- Acceptance criteria

- Testing requirements

- Documentation standards

- Review procedures

Implementation Approaches

- Stage-wise validation

- Continuous verification

- Periodic review

- Change management

The integration of process characterization and validation activities creates robust manufacturing systems.

Modern facilities employ data-driven approaches to ensure consistent product quality while maintaining regulatory compliance.

Regular reviews and updates of both characterization and validation protocols ensure continued effectiveness and alignment with current requirements.

These improvements demonstrate the value of coordinated characterization and validation efforts in pharmaceutical manufacturing.

Tools and Technologies for Process Characterization

Established process characterization methods continue to provide valuable data in pharmaceutical manufacturing.

These foundational approaches include manual sampling techniques, offline analysis methods, and basic statistical tools. Laboratory-based testing remains crucial for specific parameters, offering reliability through proven methodologies.

Modern Software Solutions

Digital transformation has revolutionized process characterization through advanced software platforms.

Manufacturing Execution Systems (MES) now integrate with Process Analytical Technology (PAT) tools, enabling real-time data collection and analysis. These systems offer:

Data Management Capabilities

- Automated data collection

- Electronic batch records

- Trend analysis tools

- Report generation systems

Quality Management Integration

- Electronic quality management systems

- Deviation tracking mechanisms

- Document control systems

- Compliance monitoring tools

AI and Machine Learning Applications

Artificial Intelligence transforms process characterization through predictive capabilities and pattern recognition.

Manufacturing facilities implementing AI solutions report efficiency improvements of 30-40% in parameter optimization and fault detection.

Predictive Analytics

- Early deviation detection

- Quality prediction models

- Optimization recommendations

- Maintenance forecasting

Pattern Recognition

- Process drift indicators

- Parameter correlations

- Quality impact patterns

- Operating efficiency opportunities

Real-Time Monitoring Systems for Process Characterization

Advanced monitoring technologies enable continuous process verification and immediate response capabilities.

These systems integrate multiple data sources to provide comprehensive process visibility.

Sensor Technologies

- Inline PAT tools

- Wireless monitoring devices

- Smart sensors

- IoT-enabled equipment

Data Integration Platforms

- Multiple data streams

- Process parameters

- Quality attributes

- Environmental conditions

Technology Selection and Implementation

Manufacturing facilities must evaluate several factors when selecting characterization technologies:

Technical Requirements

- Process complexity levels

- Data accuracy needs

- Response time requirements

- Integration capabilities

Resource Considerations

- Implementation costs

- Training requirements

- Maintenance needs

- Support availability

The evolution of process characterization tools continues to accelerate.

Manufacturing facilities implementing modern technologies alongside traditional methods report improved process understanding and control.

Implementation Strategy

- Phased implementation approaches

- Validated integration methods

- Staff training programs

- Performance verification protocols

Modern process characterization tools enable pharmaceutical manufacturers to meet increasing regulatory requirements while improving efficiency.

Regular evaluation of new technologies ensures manufacturing facilities maintain competitive advantages through optimized characterization capabilities.

Upgrade your quality management skills with Six Sigma Champion – Leadership Program

Challenges and Limitations of Process Characterization

Process characterization in pharmaceutical manufacturing faces several significant challenges that can impact effectiveness.

These challenges often stem from inadequate parameter selection and insufficient data analysis methods.

Data Quality Issues

- Incomplete data collection

- Inconsistent sampling methods

- Poor measurement accuracy

- Inadequate documentation

Resource Constraints

- Equipment availability restrictions

- Analytical method limitations

- Time constraints

- Budget restrictions

Operational Challenges

The complexity of modern manufacturing processes creates operational hurdles in characterization efforts.

Scale-Up Difficulties

- Parameter correlation changes

- Equipment differences

- Process dynamic variations

- Control strategy modifications

Knowledge Transfer Issues

- Technical expertise gaps

- Documentation inadequacies

- Communication breakdowns

- Training limitations

Strategies for Challenge Resolution

Successful process characterization requires structured approaches to overcome identified challenges. Manufacturing facilities implementing systematic resolution strategies report higher success rates in characterization studies.

Technical Solutions

- Enhanced measurement systems

- Improved sampling protocols

- Advanced analytical methods

- Validated data collection procedures

Operational Improvements

- Cross-functional team structures

- Enhanced communication protocols

- Standardized documentation methods

- Regular review procedures

Best Practices for Success in Process Characterization

Industry leaders have established proven methodologies for successful process characterization. These approaches consistently demonstrate improved outcomes across various manufacturing scenarios.

Planning and Preparation

- Detailed project planning

- Resource allocation strategies

- Risk assessment protocols

- Timeline management systems

Execution Standards

- Standard operating procedures

- Quality control protocols

- Documentation requirements

- Review mechanisms

Quality Management Integration of Process Characterization

The integration of quality management systems significantly impacts characterization success. Manufacturing facilities report fewer deviations when implementing integrated quality approaches.

Quality Control Measures

- Parameter monitoring protocols

- Deviation management procedures

- Corrective action systems

- Preventive measure implementation

Documentation Requirements

- Standard operating procedures

- Technical reports

- Validation protocols

- Change control documentation

Future Challenge Mitigation

Manufacturing facilities must prepare for emerging challenges in process characterization. Industry trends indicate increasing complexity in manufacturing processes and regulatory requirements.

Technology Integration

- Advanced monitoring systems

- Automated data collection

- Predictive analytics capabilities

- Real-time control mechanisms

Regulatory Compliance

- Evolving requirements

- Documentation standards

- Validation protocols

- Quality systems integration

Process characterization challenges require proactive management approaches.

Manufacturing facilities implementing structured resolution strategies while maintaining robust quality systems demonstrate higher success rates in characterization activities.

Regular review and updates of characterization protocols ensure continued effectiveness and regulatory compliance.

These improvements demonstrate the value of structured approaches to challenge resolution in pharmaceutical manufacturing.

Road Ahead

Process characterization has grown significantly in pharmaceutical manufacturing, driven by technological advancements and regulatory requirements.

The integration of artificial intelligence, machine learning, and real-time monitoring systems has transformed traditional characterization approaches.

The emergence of Quality by Design principles has reinforced the importance of robust process characterization methodologies.

These structured methods ensure consistent product quality while optimizing operational efficiency.

Future Directions in Process Characterization

The pharmaceutical manufacturing sector continues to advance process characterization methodologies. Industry trends indicate several emerging focus areas.

Process characterization remains fundamental to pharmaceutical manufacturing excellence.

The continued evolution of characterization methodologies, driven by technological advancement and regulatory requirements, ensures manufacturing facilities maintain competitive advantages while delivering consistent product quality.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs