The Guide to the Taguchi Method: A Robust Quality and Efficient Experimentation

Achieving robust quality and efficient production is paramount.

That’s where the revolutionary Taguchi method comes into play – a powerful approach to design of experiments and quality control that has transformed industries worldwide.

Developed by the pioneering engineer Genichi Taguchi, this methodology optimizes processes to minimize defects and variations, even in the face of uncontrollable environmental factors.

At its core, the Taguchi method leverages orthogonal arrays and signal-to-noise ratios to systematically study variables and their interactions, identifying the optimal settings for robust performance.

Key Highlights

- Theoretical foundations

- Implementation step

- Applications of the Taguchi method

- New levels of process control

- Defect reduction, and quality optimization – the Taguchi way

The Origins and Principles of the Taguchi Method

In the pursuit of quality excellence, few names resonate as powerfully as Genichi Taguchi, the visionary statistician whose groundbreaking Taguchi method revolutionized the way we approach product and process optimization.

Born in Japan in 1924, Taguchi’s pioneering work laid the foundation for a robust, systematic methodology that has transformed industries worldwide.

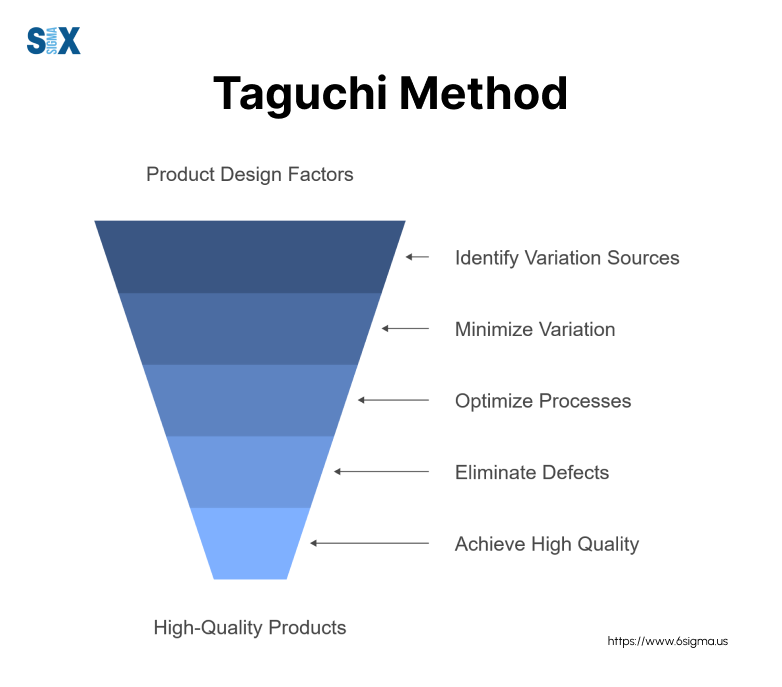

At the core of the Taguchi method lies the philosophy of “robust design” – an unwavering commitment to minimizing variations and enhancing product quality, even in the face of uncontrollable environmental factors.

Taguchi recognized that traditional quality control measures, focused solely on inspecting and rejecting defective products, were inherently flawed and costly.

Key Concepts and Terminology

The Taguchi method introduces several fundamental concepts that form the backbone of its innovative approach:

- Orthogonal Arrays: Efficient, systematic matrices that guide the experimental design, allowing for the study of multiple factors and interactions with a minimal number of trials.

- Signal-to-Noise (S/N) Ratios: Objective functions that measure the desired performance characteristics, enabling the identification of optimal settings for robust performance.

- Loss Functions: Mathematical representations of the societal and economic costs associated with poor quality, quantifying the impact of deviations from target values.

- Control and Noise Factors: Taguchi distinguishes between controllable factors (parameters that can be adjusted) and uncontrollable noise factors (environmental variables), enabling robust designs that minimize the impact of noise.

- System, Parameter, and Tolerance Design: A three-phase approach that encompasses conceptual design, optimization of control factors, and minimization of variation through tolerance design.

The Evolution of the Taguchi Method and Global Impact

While the Taguchi method initially gained traction in Japan, its transformative potential soon caught the attention of global industry leaders.

Companies like Toyota, Ford, and Boeing were among the early adopters, harnessing the power of Taguchi’s principles to streamline their manufacturing processes and enhance product quality.

As the methodology’s success stories multiplied, its influence spread across diverse sectors, from engineering and biotechnology to marketing and advertising.

Today, the Taguchi method stands as a testament to the enduring impact of Genichi Taguchi’s vision, empowering organizations worldwide to achieve unprecedented levels of quality, efficiency, and customer satisfaction.

Revolutionize your approach to quality control with our Yellow Belt course which equips you with essential tools like the Taguchi method to drive robust design and minimize defects.

Implementing the Taguchi Method: A Step-by-Step Guide

Taguchi method is a systematic, efficient approach to experimental design and optimization.

Whether you’re seeking to enhance product quality, streamline manufacturing processes, or fine-tune service offerings, this step-by-step guide will empower you to harness the full potential of Taguchi’s groundbreaking principles.

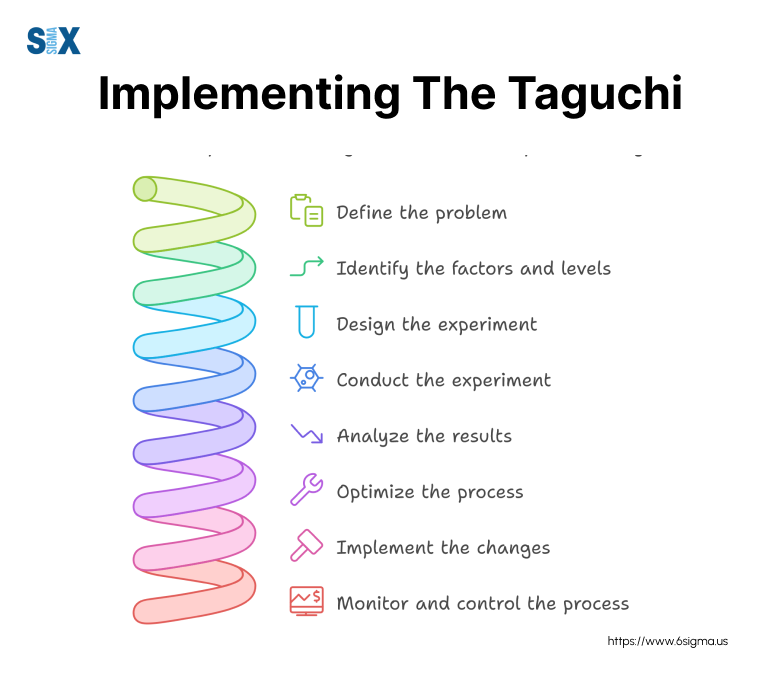

Step 1: Define the Problem and Identify Factors

The first step in the Taguchi method for optimization is to clearly define the problem or objective you wish to address.

This could be minimizing defects in a manufacturing process, maximizing the yield of a chemical reaction, or optimizing the performance of a marketing campaign.

Next, identify the factors that can be controlled or manipulated, known as control factors.

These may include parameters such as temperature, pressure, or ingredient ratios. Determine the levels or settings at which each control factor will be varied during the experiments.

Additionally, consider the noise factors – the uncontrollable environmental variables that can impact the outcome. Understanding these factors is crucial for designing a robust process that can withstand real-world variations.

Step 2: Select the Appropriate Orthogonal Array

The Taguchi method employs orthogonal arrays, a specialized experimental design technique that allows for the study of multiple factors and their interactions with a minimal number of trials.

Selecting the appropriate orthogonal array is essential for efficient design of experiments.

To choose the right array, consider the number of control factors and the levels at which they will be varied.

For instance, if you have three control factors with two levels each, the L4 orthogonal array would be suitable. Taguchi method examples and guidelines are widely available to assist in array selection.

Step 3: Conduct Experiments and Collect Data

With the orthogonal array determined, it’s time to conduct the experiments outlined in the matrix.

Follow the prescribed combinations of factor levels and meticulously record the resulting data. Maintaining accurate records is crucial for subsequent analysis.

In some cases, a noise matrix may be incorporated to simulate real-world conditions and assess the impact of noise factors on the process or product performance.

This approach ensures that the optimized settings are truly robust and insensitive to uncontrollable variations.

Step 4: Analyze Data and Optimize Settings

The heart of the Taguchi method lies in the analysis of the experimental data.

This involves calculating and interpreting the signal-to-noise (S/N) ratios, objective functions that measure the desired performance characteristics and enable the identification of optimal settings for robust performance.

Through techniques like analysis of variance (ANOVA), you can determine the relative influence of each control factor and their interactions on the outcome.

This analysis guides the selection of factor levels that minimize variability and achieve the desired target or specification.

Step 5: Validate and Implement Optimized Settings

With the optimal factor settings identified, it’s essential to conduct confirmation experiments to validate the predicted improvements.

These experiments serve as a final check before implementing the optimized settings in the actual production or service environment.

Once validated, implement the optimized settings and establish rigorous monitoring and control measures.

Continuous monitoring is crucial to ensure that the process remains robust and that any deviations from the optimal conditions are promptly addressed.

By following this comprehensive step-by-step guide, you’ll be well-equipped to leverage the power of the Taguchi method and unlock new levels of process optimization, quality improvement, and robust performance – no matter your industry or application.

Take your process improvement abilities to the next level. Learn to apply the Taguchi method and develop robust designs in our comprehensive Green Belt program.

Advantages and Limitations of the Taguchi Method

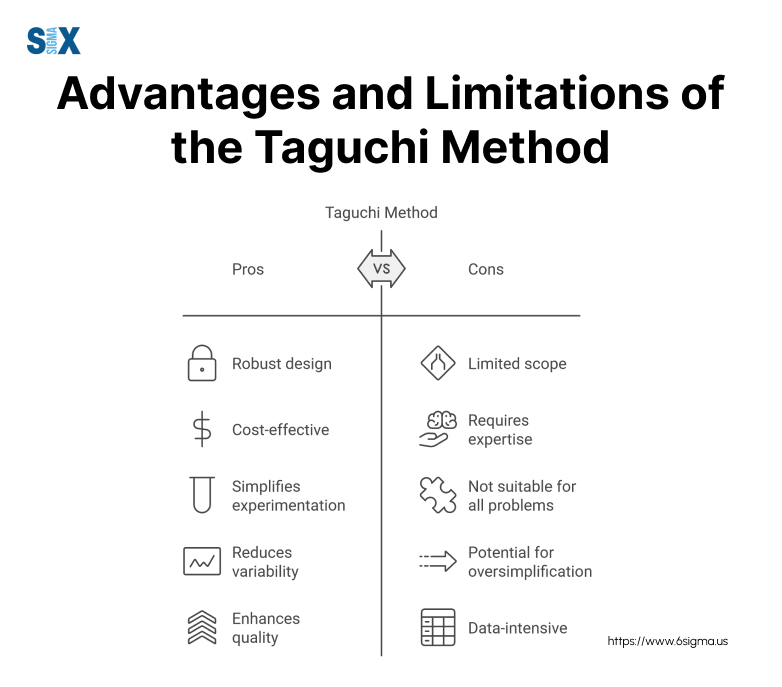

Like any powerful methodology, the Taguchi method comes with its own set of advantages and limitations.

Understanding these strengths and weaknesses is crucial for leveraging the full potential of this approach while recognizing its boundaries and areas for improvement.

Advantages

- Efficiency in Experimental Design and Data Collection: One of the Taguchi method’s most significant advantages is its ability to study multiple factors simultaneously with a minimal number of experiments. Thanks to the use of orthogonal arrays, practitioners can efficiently explore various factor combinations, saving time and resources compared to traditional experimental designs.

- Robustness and Insensitivity to Uncontrollable Factors: A core principle of the Taguchi method is achieving robust designs that are insensitive to uncontrollable noise factors. By optimizing control factors and minimizing the impact of environmental variations, the method enables the creation of products or processes that consistently perform well, even under varying real-world conditions.

- Cost Savings Through Minimized Defects and Rework: By prioritizing quality and robustness from the design phase, the Taguchi method helps organizations reduce defects, rework, and waste, leading to significant cost savings throughout the product lifecycle. This proactive approach to quality control is particularly valuable in manufacturing and production environments.

- Continuous Quality Improvement and Optimization: The Taguchi method provides a systematic framework for continuous improvement and optimization. By analyzing experimental data and identifying optimal factor settings, organizations can iteratively refine their processes, driving ongoing quality enhancements and performance gains.

- Applicability Across Diverse Industries and Processes: While originally developed for manufacturing, the Taguchi method has proven its versatility and adaptability across a wide range of industries and processes. From engineering and biotechnology to marketing and service industries, this methodology has found applications in numerous domains, making it a valuable tool for quality professionals and process optimizers.

Criticisms and Limitations

Despite its strengths, the Taguchi method has faced several criticisms and limitations from the statistical community:

- Efficiency and Statistical Rigor: Some statisticians have questioned the efficiency of certain Taguchi proposals, particularly when it comes to handling complex interactions between factors. While the method excels in studying main effects, its approach to interactions has been a subject of debate.

- Limitations in Handling Complex Interactions: Due to the use of saturated orthogonal arrays, the Taguchi method may not fully capture or resolve higher-order interactions between factors. This limitation has led to alternative approaches, such as response surface methodology (RSM), which allows for more flexibility in studying complex interactions.

- Lack of Theoretical Foundations: Critiques have been raised regarding the lack of solid theoretical foundations underpinning certain aspects of the Taguchi method, particularly the use of signal-to-noise ratios as objective functions for optimization.

It’s important to note that while these limitations exist, they do not diminish the overall value and impact of the Taguchi method.

Many practitioners and researchers have defended the method’s principles and offered counterarguments to these criticisms, highlighting the practical benefits and successful applications across various industries.

Comparison of the Taguchi Method with Other Methodologies

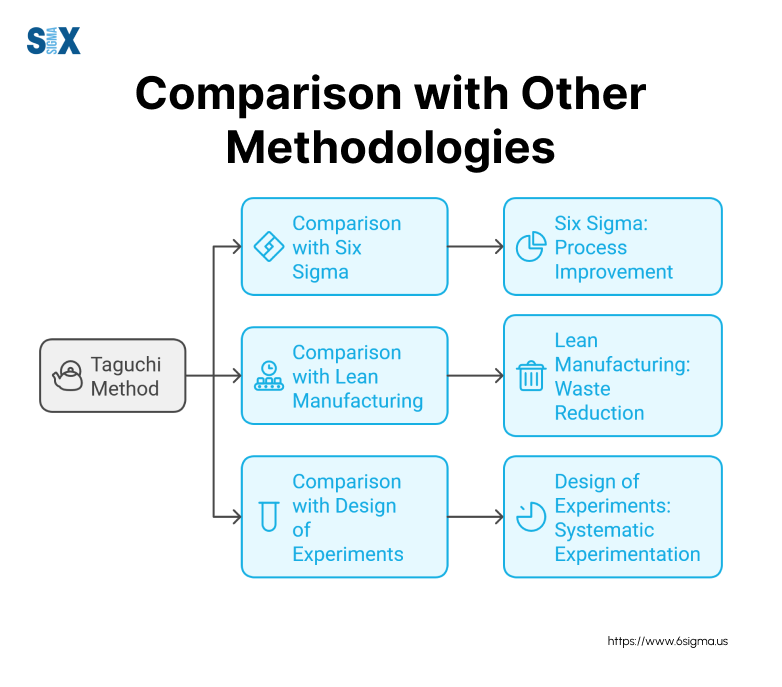

To fully appreciate the Taguchi method, it’s useful to compare it with other experimental design and quality control methodologies:

- Factorial Designs: Traditional factorial designs excel in studying factor interactions but can quickly become resource-intensive as the number of factors increases. The Taguchi method offers a more efficient alternative for scenarios with a large number of factors and limited interactions.

- Response Surface Methodology (RSM): RSM is a powerful technique for studying complex interactions and optimizing processes. It complements the Taguchi method by providing a more flexible approach for studying higher-order interactions and nonlinear relationships, while the Taguchi method excels in robustness and efficiency.

- Integration with Other Methodologies: Many practitioners have explored the potential for integrating or combining the Taguchi method with other quality control or experimental design techniques. By leveraging the strengths of multiple methodologies, organizations can create hybrid approaches tailored to their specific needs and challenges.

Ultimately, the choice of methodology will depend on the nature of the problem, the number of factors involved, the complexity of interactions, and the specific goals of the organization.

By understanding the advantages and limitations of each approach, quality professionals can make informed decisions and leverage the most appropriate techniques for their needs.

Become a process optimization expert with our Black Belt course which prepares you to lead cutting-edge quality initiatives and drive strategic excellence through advanced methodologies like the Taguchi method.

Conclusion

Taguchi method stands as a beacon of innovation and robustness. Developed by the visionary Genichi Taguchi, this groundbreaking methodology has transformed industries worldwide, empowering organizations to achieve unprecedented levels of quality and efficiency.

Through its emphasis on robust design, the Taguchi method equips you with the tools to minimize variations and deliver products or services that consistently meet or exceed customer expectations, even in the face of uncontrollable environmental factors.

From manufacturing and engineering to biotechnology and marketing, this versatile approach has proven its value across diverse domains.

While acknowledging the limitations and critiques surrounding the method, its numerous advantages – including efficiency in experimental design, cost savings through reduced defects, and continuous quality improvement – make it an invaluable asset for any organization committed to excellence.

The path to quality excellence starts here. Join the ranks of industry leaders and embrace the power of the Taguchi method today.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs