The Guide to Quality Control in Manufacturing: Strategies, Tools, and Best Practices

Quality control in manufacturing forms the backbone of successful production operations worldwide.

Modern manufacturing facilities rely on robust quality control processes to maintain product excellence, reduce waste, and ensure customer satisfaction.

Manufacturing quality control involves systematic monitoring and evaluation of production processes to meet specified standards.

Key Highlights

- Essential quality control methodologies and tools

- Implementation strategies for various industries

- Technology integration in quality processes

- Cost-effective quality control solutions

- Future trends shaping manufacturing QC

What Is Quality Control in Manufacturing?

Quality control in manufacturing represents a set of procedures and standards that ensure products meet specified requirements.

These procedures verify product quality through various stages of production, from raw materials to finished goods.

Basic Principles of Manufacturing Quality Control

Manufacturing quality control focuses on preventing defects and maintaining consistent product standards.

This process involves regular testing, inspection, and measurement of products against predetermined specifications.

Quality control teams monitor production processes, identify deviations, and implement corrective actions to maintain product quality.

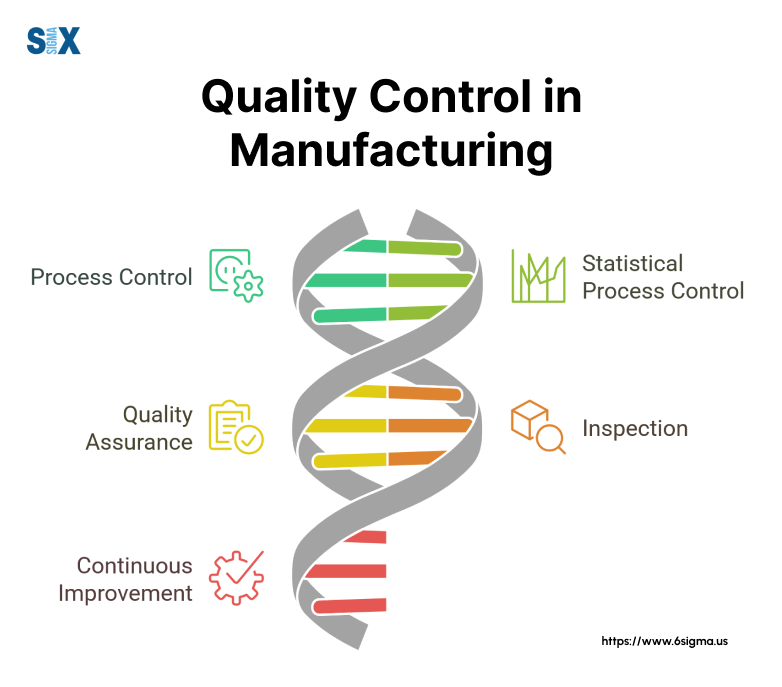

The main elements of quality control in manufacturing include:

- Product inspection and testing

- Process monitoring and control

- Documentation and reporting

- Corrective action implementation

- Statistical analysis of quality data

The Role of Quality Control in Modern Manufacturing

Quality control plays a vital role in manufacturing operations by ensuring product consistency and reliability.

Modern manufacturing facilities rely on quality control processes to reduce waste, optimize production efficiency, and maintain customer satisfaction.

These processes help manufacturers identify and address quality issues before products reach customers.

Manufacturing quality control impacts several key areas:

- Product reliability and consistency

- Production cost optimization

- Customer satisfaction levels

- Regulatory compliance

- Brand reputation management

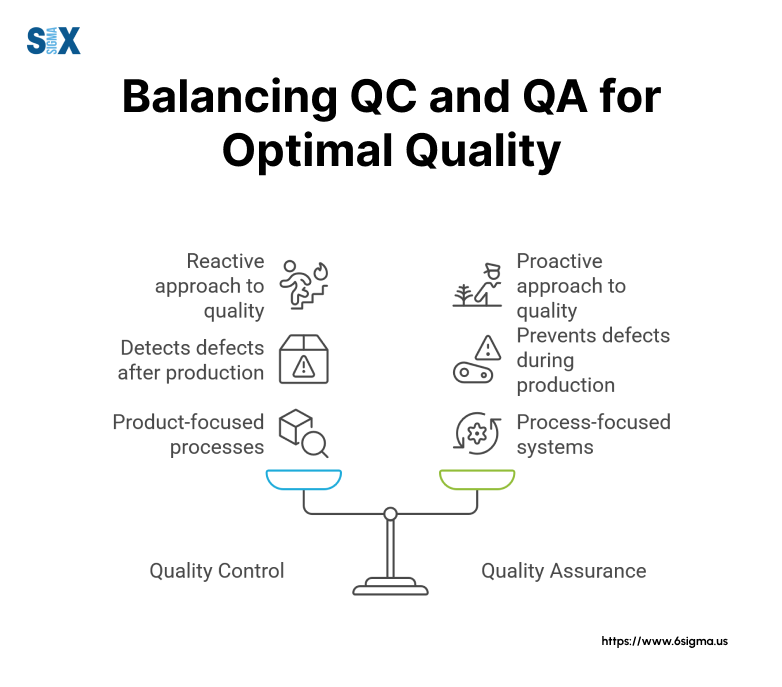

Quality Control vs. Quality Assurance: Understanding the Distinction

While often used interchangeably, quality control and quality assurance serve different purposes in manufacturing.

Quality control focuses on product testing and inspection to identify defects, while quality assurance involves preventing quality issues through process improvement and standardization.

Quality Control:

- Identifies defects in finished products

- Tests products against specifications

- Implements immediate corrective actions

- Focuses on current production

Quality Assurance:

- Prevents quality issues through process design

- Establishes quality standards and procedures

- Creates long-term quality improvement plans

- Focuses on future production

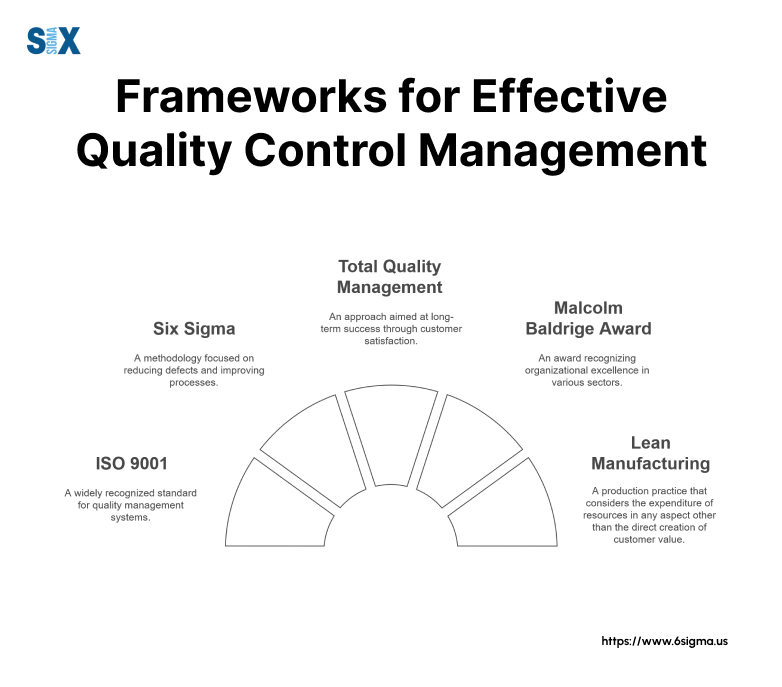

Quality Control Standards in Manufacturing

Manufacturing quality control adheres to various international standards and regulations.

These standards provide frameworks for implementing effective quality control processes.

Organizations like ISO (International Organization for Standardization) develop and maintain these standards, which help manufacturers establish consistent quality control practices.

Key standards include:

- ISO 9001:2015 Quality Management Systems

- Six Sigma methodology

- Good Manufacturing Practice (GMP)

- Industry-specific quality standards

These standards guide manufacturers in developing robust quality control systems that align with industry best practices and regulatory requirements. By following these standards, manufacturers can ensure their quality control processes meet international benchmarks and customer expectations.

Common Quality Control Methodologies in Manufacturing

Manufacturing facilities employ various quality control methods to maintain product excellence and operational efficiency.

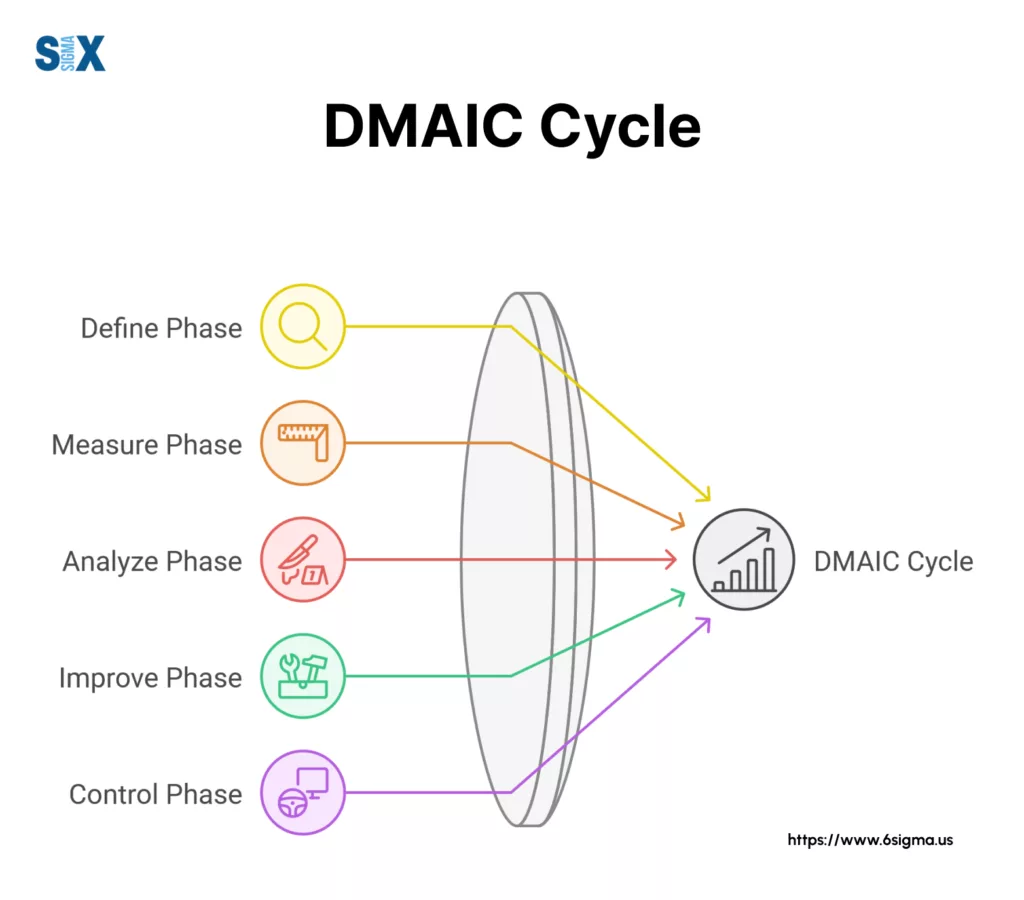

Six Sigma Methodology

Six Sigma represents a data-driven approach to quality control in manufacturing that aims to reduce defects to 3.4 per million opportunities.

This methodology uses statistical tools and process improvement techniques to identify and eliminate variations in manufacturing processes.

The DMAIC framework guides Six Sigma implementation:

- Define quality objectives and project scope

- Measure current process performance

- Analyze data to identify root causes

- Improve processes through targeted solutions

- Control processes to maintain improvements

Total Quality Management (TQM)

Total Quality Management emphasizes organization-wide commitment to quality control in manufacturing operations.

Key elements of TQM include:

- Employee involvement at all levels

- Process-centered approach

- Integrated system management

- Strategic quality planning

- Data-driven decision making

Manufacturing facilities implementing TQM often see improved product quality, reduced waste, and enhanced employee engagement.

The success of TQM relies heavily on leadership commitment and cultural transformation within the organization.

Lean Manufacturing Quality Control

Lean manufacturing and quality control work together to eliminate waste while maintaining product excellence.

This methodology focuses on streamlining production processes and implementing quality checks at each stage of manufacturing.

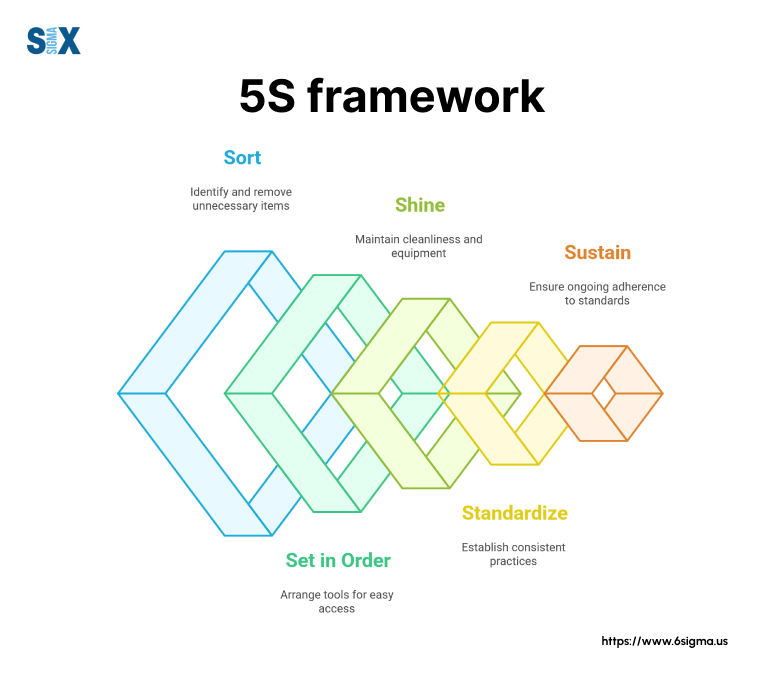

The 5S framework supports lean quality control:

- Sort (organize workspace)

- Set in order (arrange tools and materials)

- Shine (clean and inspect)

- Standardize (establish procedures)

- Sustain (maintain improvements)

Change your manufacturing processes with Lean methodologies. Reduce cycle times and boost production efficiency with our Lean Introduction course.

Statistical Process Control (SPC)

Statistical Process Control uses statistical methods to monitor and control manufacturing processes.

This methodology helps quality control teams identify process variations and implement corrective actions before defects occur.

SPC tools include:

- Control charts

- Process capability studies

- Sampling plans

- Root cause analysis

- Trend analysis

Manufacturing quality control teams use these tools to track process performance and maintain consistent product quality.

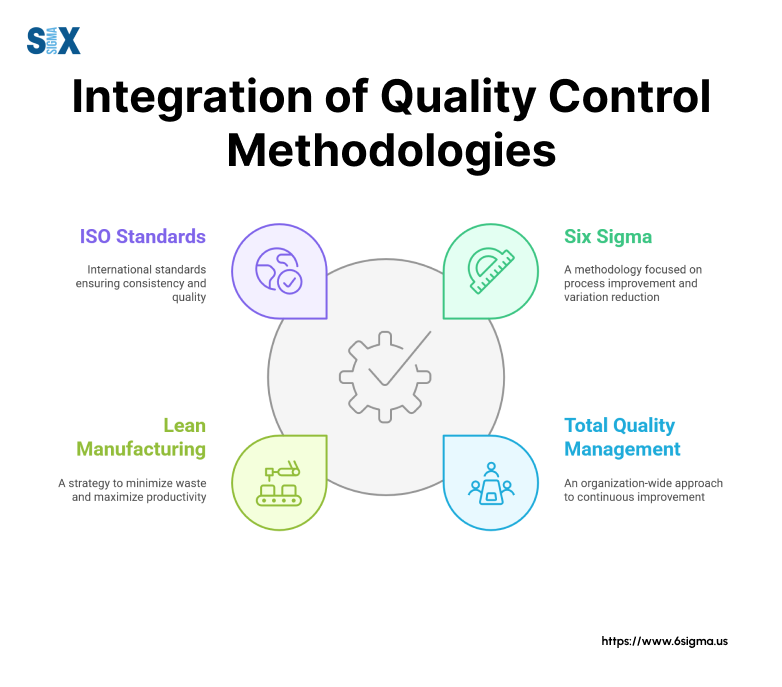

Integration of Quality Control Methods

Modern manufacturing facilities often combine multiple quality control methods to create robust quality management systems.

This integrated approach allows manufacturers to leverage the strengths of each methodology while addressing specific production challenges.

Success factors for methodology integration:

- Clear alignment with business objectives

- Strong leadership support

- Employee training and engagement

- Regular assessment and adjustment

- Technology enablement

These quality control methods continue to evolve with technological advancements and changing manufacturing requirements.

The selection and implementation of these methodologies should align with specific manufacturing processes, product requirements, and organizational capabilities.

Implementing a Quality Control Plan in Manufacturing

Successful quality control in manufacturing requires a well-structured implementation plan.

Manufacturing facilities must develop systematic approaches to ensure consistent product quality while maintaining operational efficiency.

Creating an Effective Quality Control Plan

The development of a quality control process in manufacturing begins with careful planning and clear objectives.

Manufacturing teams must first identify critical quality parameters and establish measurement methods for each production phase.

Essential planning steps include:

- Defining quality objectives and metrics

- Identifying critical control points

- Establishing inspection methods

- Determining sampling frequencies

- Setting acceptance criteria

- Creating documentation procedures

Key Components of Manufacturing Quality Control

Quality control procedures for manufacturing must include several vital components to ensure effectiveness.

These elements work together to create a robust quality management system that maintains product excellence throughout the production process.

Primary components include:

- Quality specifications and standards

- Inspection and testing protocols

- Documentation and record-keeping systems

- Non-conformance procedures

- Corrective action protocols

- Performance monitoring systems

Establishing Quality Standards and Specifications

Manufacturing quality control relies on clear, measurable standards that define acceptable product characteristics.

These standards must align with customer requirements, industry regulations, and business objectives.

Standard development process:

- Research industry requirements

- Review customer specifications

- Analyze production capabilities

- Document quality parameters

- Create measurement protocols

Employee Training for Quality Control

Effective quality control procedures in manufacturing depend heavily on well-trained personnel.

Training programs must equip employees with the knowledge and skills needed to maintain quality standards throughout the production process.

Training program elements should cover:

- Quality control fundamentals

- Inspection techniques

- Documentation requirements

- Equipment operation

- Problem-solving methods

- Safety procedures

Quality Control Documentation and Procedures

Manufacturing facilities must maintain detailed documentation of their quality control processes.

These documents serve as guidelines for daily operations and provide evidence of quality control activities.

Required documentation includes:

- Standard Operating Procedures (SOPs)

- Quality Control Manuals

- Inspection Records

- Training Materials

- Audit Reports

Monitoring and Improving Quality Control Systems

Regular assessment and improvement of quality control processes ensure their continued effectiveness.

Manufacturing teams should establish review procedures to evaluate and enhance their quality control systems.

Key monitoring activities:

- Regular performance reviews

- Quality metrics analysis

- Process audits

- Employee feedback sessions

- System updates and improvements

The implementation of quality control in manufacturing requires ongoing commitment and resources.

Success depends on proper planning, clear procedures, trained personnel, and continuous monitoring.

Regular evaluation and adjustment of these elements ensure the quality control system remains effective and adapts to changing manufacturing requirements.

Essential Quality Control Tools and Techniques

Manufacturing facilities rely on various quality control tools to maintain product excellence and process efficiency.

These tools range from basic statistical methods to advanced software solutions, each serving specific functions in the quality control process.

Statistical Tools for Manufacturing Quality Control

Statistical tools form the foundation of effective quality control in manufacturing. These tools help quality teams analyze data, identify trends, and make informed decisions about process improvements.

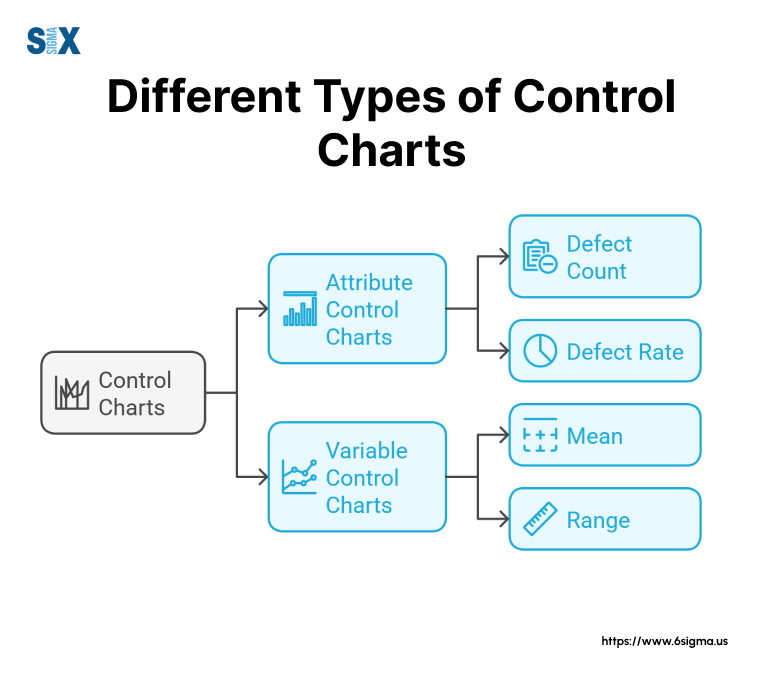

Control Charts:

Control charts monitor process stability and variation over time.

Manufacturing teams use these charts to:

- Track process performance

- Identify unusual patterns

- Detect process shifts

- Maintain statistical control

- Document quality improvements

Histograms and Pareto Analysis:

These visualization tools help identify patterns and priorities in quality control data.

Histograms show data distribution patterns, while Pareto charts highlight the most significant factors affecting quality issues.

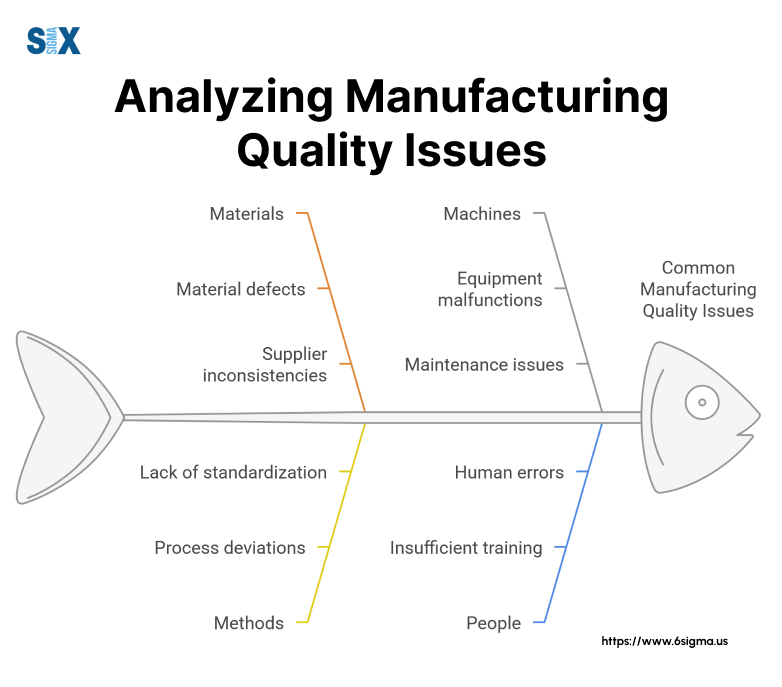

Root Cause Analysis Methods

Root cause analysis tools help manufacturing teams identify the underlying causes of quality issues.

These techniques ensure that quality problems are solved at their source rather than just treating symptoms.

Common analysis methods include:

- Ishikawa (Fishbone) Diagrams

- 5-Why Analysis

- Fault Tree Analysis

- Process Mapping

- Cause and Effect Matrix

Failure Mode and Effects Analysis (FMEA)

FMEA serves as a preventive quality control tool in manufacturing by identifying potential failure points before they occur.

This systematic approach helps teams:

- Identify possible failure modes

- Assess potential impacts

- Evaluate risk levels

- Develop preventive measures

- Track improvement actions

Manufacturing teams use FMEA during product design and process development stages to minimize quality risks and optimize production processes.

Quality Control Software Solutions

Modern software for quality control in manufacturing has transformed how facilities manage quality processes.

These digital tools integrate various quality control functions into unified platforms.

Key software capabilities:

- Real-time data collection

- Statistical process control

- Document management

- Workflow automation

- Performance reporting

- Compliance tracking

Advanced Measurement and Testing Equipment

Quality control tools in manufacturing include specialized equipment for measuring and testing product characteristics.

These tools ensure accurate quality assessments throughout the production process.

Essential measurement tools:

- Coordinate Measuring Machines (CMM)

- Optical Measurement Systems

- Material Testing Equipment

- Calibration Devices

- Environmental Testing Chambers

Digital Quality Management Systems

Digital systems integrate various quality control tools and techniques into unified platforms.

These systems help manufacturing facilities:

- Centralize quality data

- Automate routine tasks

- Track quality metrics

- Generate reports

- Manage documentation

Selecting the Right Quality Control Tools

Manufacturing facilities must choose quality control tools based on their specific needs and capabilities.

Factors to consider include:

- Production volume and complexity

- Quality requirements

- Available resources

- Technical capabilities

- Budget constraints

The effective use of these quality control tools requires proper training and regular evaluation of their effectiveness.

Measuring and Analyzing Product Quality

Manufacturing quality control relies on accurate measurement and analysis of product characteristics.

Effective quality measurement systems help manufacturers identify issues, track improvements, and maintain consistent product standards throughout the production process.

Key Performance Indicators for Quality Control

Quality control KPIs provide measurable values that track manufacturing performance and product quality.

These indicators help manufacturing teams assess production efficiency and product consistency.

Essential quality KPIs include:

- Defect rates and types

- First-pass yield

- Scrap and rework rates

- Customer complaint rates

- On-time delivery performance

Data Collection Methods in Manufacturing

Production quality control requires systematic data collection methods to ensure accurate quality assessment.

Key data collection approaches:

- Automated sensor measurements

- Manual inspection records

- Product testing results

- Process parameter monitoring

- Customer feedback tracking

Quality Control Analytics and Reporting

Data analytics transforms raw quality data into actionable insights for manufacturing teams.

Modern analytics tools help identify patterns, predict potential issues, and optimize quality control processes.

Analytics applications include:

- Trend analysis

- Predictive maintenance

- Process optimization

- Quality cost analysis

- Performance bench-marking

Production Quality Control Checklist Implementation

Quality control checklists ensure consistent monitoring of critical production parameters.

These checklists guide operators through necessary quality checks and documentation requirements.

Essential checklist components:

- Pre-production setup verification

- In-process quality checks

- Equipment calibration status

- Product specification compliance

- Documentation requirements

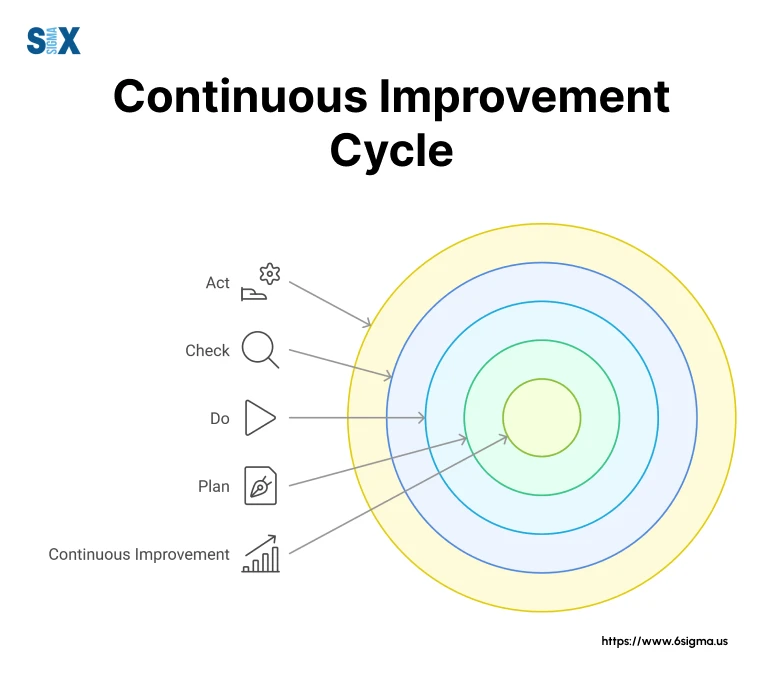

Continuous Quality Improvement Strategies

Manufacturing facilities must implement ongoing improvement strategies to maintain and enhance product quality.

These strategies help identify opportunities for quality enhancement and process optimization.

Improvement methods include:

- Regular process audits

- Employee suggestion programs

- Quality circles

- Kaizen events

- Performance reviews

Quality Measurement Technology Integration

Modern manufacturing facilities integrate advanced measurement technologies into their quality control processes.

These technologies enhance accuracy and efficiency in quality monitoring.

Technology applications:

- Automated inspection systems

- Vision systems

- 3D measurement tools

- Real-time monitoring devices

- Data integration platforms

Quality Control Documentation and Reporting

Proper documentation supports effective quality control in manufacturing by tracking measurements, analyses, and improvements.

Manufacturing teams must maintain detailed records of quality-related activities.

Documentation requirements:

- Inspection records

- Test results

- Calibration certificates

- Corrective actions

- Improvement initiatives

Performance Review and Adjustment

Regular review of quality measurements helps manufacturing teams identify areas for improvement and adjust quality control processes accordingly.

These reviews ensure quality control systems remain effective and efficient.

Review elements include:

- KPI performance analysis

- Process capability studies

- Quality cost evaluation

- Resource utilization assessment

- System effectiveness review

The measurement and analysis of product quality require ongoing attention and adjustment.

Manufacturing facilities must regularly evaluate their quality control systems and update them to meet changing production requirements and customer expectations.

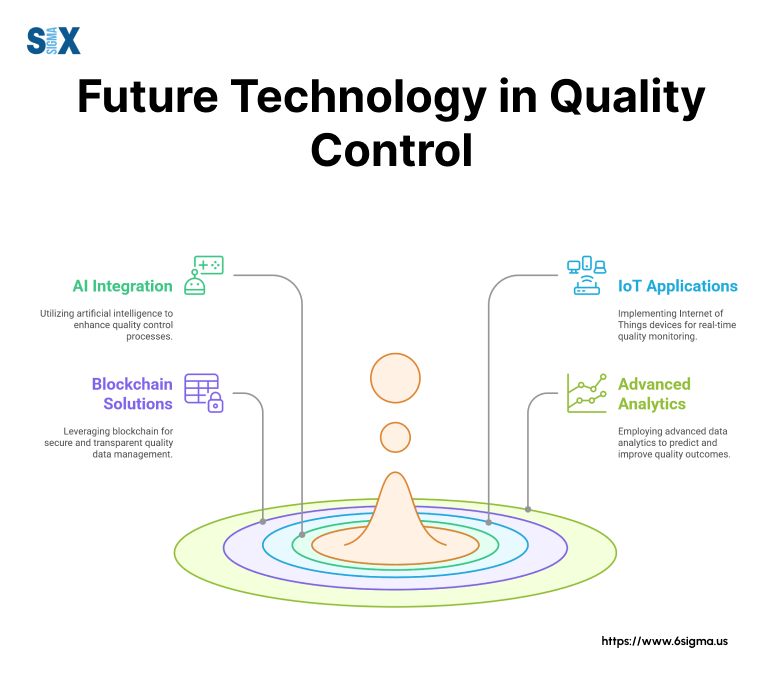

Technology Integration in Quality Control

Modern manufacturing facilities increasingly rely on advanced technologies to enhance quality control processes.

These technological solutions transform traditional quality inspection methods into sophisticated, data-driven systems that improve accuracy and efficiency.

Industry 4.0 in Manufacturing Quality Control

Industry 4.0 technologies revolutionize quality control by connecting machines, systems, and processes through digital networks.

This connectivity enables real-time monitoring and adjustment of production parameters to maintain product quality.

Key Industry 4.0 applications include:

- Smart sensors and actuators

- Digital twin technology

- Cloud computing platforms

- Advanced analytics systems

- Interconnected quality systems

Automation and Robotics in Quality Inspection

Automated inspection systems and robots perform quality checks with greater precision and consistency than manual methods.

These systems operate continuously, reducing inspection time while improving accuracy.

Robotic inspection capabilities:

- High-speed visual inspection

- Dimensional measurement

- Surface defect detection

- Material composition analysis

- Assembly verification

AI and Machine Learning Applications

Artificial Intelligence and machine learning algorithms enhance quality control by identifying patterns and predicting potential quality issues before they occur.

These technologies analyze vast amounts of production data to optimize quality processes.

AI applications in quality control:

- Defect prediction models

- Pattern recognition systems

- Quality parameter optimization

- Automated decision support

- Predictive maintenance

IoT and Real-Time Quality Monitoring

Internet of Things (IoT) devices enable continuous quality monitoring throughout the production process.

These connected sensors and devices provide immediate feedback on product quality and process parameters.

IoT monitoring capabilities:

- Temperature and humidity tracking

- Vibration analysis

- Process parameter monitoring

- Equipment performance tracking

- Quality data collection

Advanced Measurement Technologies

Modern quality inspection systems incorporate sophisticated measurement technologies that provide precise data for quality control decisions.

These technologies ensure accurate assessment of product characteristics.

Measurement systems include:

- 3D scanning equipment

- Laser measurement devices

- Spectral analysis tools

- Thermal imaging systems

- Ultrasonic testing equipment

Data Integration and Analysis

Digital quality control systems integrate data from multiple sources to provide unified quality management platforms.

These systems enable real-time analysis and reporting of quality metrics.

Integration features:

- Centralized data storage

- Real-time analytics

- Automated reporting

- Quality trend analysis

- Performance dashboards

Remote Quality Control Capabilities

Remote monitoring and control systems allow quality teams to oversee production processes from any location.

These systems provide flexibility while maintaining strict quality standards.

Remote capabilities include:

- Virtual inspection systems

- Remote process monitoring

- Digital quality reviews

- Online collaboration tools

- Mobile quality applications

Future Technology Trends

Emerging technologies continue to shape the future of quality control in manufacturing.

New developments promise even greater capabilities for maintaining and improving product quality.

Upcoming trends:

- Quantum computing applications

- Advanced robotics systems

- Extended reality inspection

- Blockchain quality tracking

- 5G-enabled quality control

The integration of these technologies requires careful planning and implementation.

Manufacturing facilities must evaluate their specific needs and capabilities when selecting and implementing new quality control technologies.

Challenges and Solutions in Manufacturing Quality Control

Manufacturing facilities face numerous quality control challenges that require strategic solutions and continuous adaptation.

Common Quality Control Challenges

Quality control issues in manufacturing often stem from multiple sources, affecting both production processes and final product quality.

These challenges require systematic approaches for effective resolution.

Primary challenges include:

- Inconsistent measurement methods

- Equipment calibration drift

- Operator training gaps

- Process variation

- Documentation errors

Process Variation Management

Process variations present significant challenges for manufacturer quality control systems.

These variations can stem from multiple sources and require different management approaches.

Key variation sources:

- Material inconsistencies

- Equipment wear

- Environmental conditions

- Operator differences

- Tool degradation

Optimize your production with advanced Lean techniques and level up your manufacturing efficiency with Lean Master Certification

Resource Allocation Challenges

Manufacturing facilities must balance quality control requirements with available resources. This balance affects staffing, equipment investment, and quality system implementation.

Resource considerations include:

- Quality control staff requirements

- Equipment investment needs

- Training program costs

- Technology implementation expenses

- Maintenance requirements

Strategic Solutions for Quality Challenges

Effective solutions for quality control challenges require strategic planning and systematic implementation.

These solutions must address both immediate issues and long-term quality objectives.

Solution strategies include:

- Standardized work procedures

- Advanced training programs

- Technology integration

- Process automation

- Quality system optimization

Employee Engagement Solutions

Quality control success depends heavily on employee engagement and participation. Manufacturing facilities must develop strategies to involve all staff in quality improvement efforts.

Engagement strategies include:

- Quality circles implementation

- Suggestion systems

- Recognition programs

- Skills development

- Cross-functional teams

Technology-Based Solutions

Modern technology offers solutions to many traditional quality control challenges.

These solutions improve accuracy, efficiency, and consistency in quality management.

Technical solutions include:

- Automated inspection systems

- Real-time monitoring tools

- Digital documentation systems

- Predictive maintenance programs

- Quality analytics platforms

Continuous Improvement Approaches

Manufacturing quality control requires ongoing improvement efforts to address evolving challenges.

These approaches help facilities maintain and enhance their quality systems.

Improvement methods include:

- Regular system audits

- Performance reviews

- Process optimization

- Technology updates

- Training refreshers

The resolution of quality control challenges requires dedication, resources, and systematic approaches.

Manufacturing facilities must regularly evaluate their quality systems and implement appropriate solutions to maintain product excellence.

Cost Considerations and ROI of Quality Control

Quality control in manufacturing requires significant investment, yet delivers substantial returns when properly implemented.

Understanding the financial aspects helps manufacturers make informed decisions about quality control investments and improvements.

Cost-Effective Quality Control Implementation

Manufacturing facilities must balance quality requirements with budget constraints. Strategic implementation of quality control measures helps optimize both quality and costs.

Essential cost considerations:

- Equipment and technology investments

- Training and development expenses

- Staffing requirements

- Maintenance costs

- Documentation systems

Quality Control ROI Calculations

Return on investment calculations help justify quality control expenditures.

These calculations consider both direct and indirect benefits of quality improvement initiatives.

Key ROI factors include:

- Reduced scrap and rework

- Decreased warranty claims

- Improved customer satisfaction

- Enhanced production efficiency

- Lower inspection costs

Quality-Cost Balance in Manufacturing

Finding the optimal balance between quality and cost requires careful analysis of manufacturing processes and requirements.

This balance ensures sustainable quality control practices.

Balance considerations include:

- Prevention costs

- Appraisal expenses

- Internal failure costs

- External failure impacts

- Customer satisfaction levels

Road Ahead

Quality control in manufacturing continues to evolve with technological advancements and changing market demands.

The implementation of effective quality control systems remains crucial for manufacturing success.

Future of Manufacturing Quality Control

The manufacturing industry faces ongoing changes in quality control requirements and capabilities. Adaptation to these changes ensures continued success in quality management.

Future considerations include:

- Digital transformation

- Automation advancement

- Sustainable practices

- Remote monitoring capabilities

- AI integration

Implementation Recommendations

Manufacturing facilities should take specific steps to enhance their quality control systems:

Action items include:

- Assess current quality systems

- Identify improvement opportunities

- Develop implementation plans

- Train staff effectively

- Monitor and adjust processes

Quality control in manufacturing requires ongoing commitment and investment. The benefits of proper implementation far outweigh the costs, leading to improved product quality, customer satisfaction, and business success.

Success depends on balancing quality requirements with cost considerations while maintaining focus on continuous improvement.

These insights and recommendations provide a foundation for implementing and maintaining effective quality control systems in manufacturing operations.

The future of manufacturing quality control lies in the strategic integration of new technologies and methodologies while maintaining focus on fundamental quality principles.

Organizations that embrace these changes while managing costs effectively will achieve sustainable success in their quality control efforts.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs