Understanding Cycle Time: Definition, Calculation, and Importance

For enterprises crafting, producing, or running workflows repetitively, cycle time/duration is crucial for effectiveness estimation and better spotting.

Cycle time, likewise termed lead time alludes to a full period from starting one repeating assignment to end whether vehicle assembly lines, programming undertakings, or building activities, abbreviating it unlocks refined functioning, waste deduction, and greatest yields.

This central idea guides production, task administration, and other areas. It totals the timeframe expected to finish one cycle from beginning to end. Cycle time checks how long it takes to generate one creation or benefit unit.

Key Highlights

- Cycle duration estimates spotlight numerous fields. It steps full eras needed finishing one repeating operation cycle.

- Calculating and dissecting the aid hindrance distinguishing, cycle refining, and effectiveness advances.

- The notation furnishes important consciousness for ability preparation, asset distribution, and conveyance projections.

- Versatile approaches like Kanban and Scrum utilize it as center insights for foreseeability and procedure enhancements.

What is Cycle Time?

Cycle time depicts the time taken from starting an assignment until ends, including any lingering times, holding times, or postponements.

It totals the time expected to change crude resources or contributions into completed yields or administrations. Cycle time involves all strides, exercises, and tasks included in the creation procedure.

Importance of Cycle Time

Measuring and optimizing cycle times is crucial for several reasons:

Productivity and Efficiency

A shorter cycle time indicates a more efficient and productive process. By reducing it, businesses can increase their output and throughput without necessarily increasing resources or capacity.

Cost Reduction

Longer cycle times often translate to higher costs, as they involve more labor, overhead, and inventory carrying costs. Minimizing it can help businesses reduce their operational costs and improve profitability.

Customer Satisfaction

In many industries, shorter cycle times lead to faster delivery times, which can improve customer satisfaction and competitiveness. Customers generally prefer products or services that can be delivered quickly without compromising quality.

Process Improvement

Analyzing it can reveal bottlenecks, inefficiencies, and areas for improvement within a process. Six Sigma certification involves training to systematically identify inefficiencies by leveraging data-driven methodologies to streamline operations and reduce cycle times.

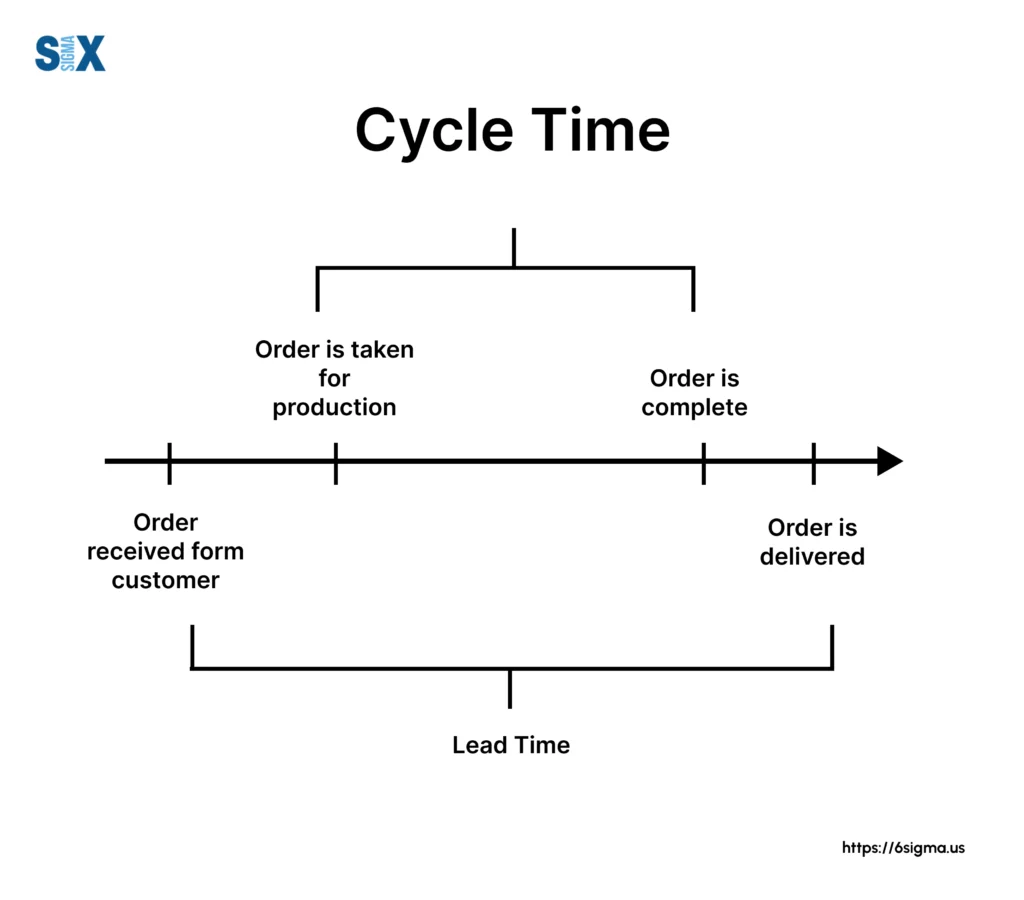

Cycle Time vs. Lead Time

It’s important to distinguish cycle time from lead time, as these two terms are often confused. Lead time is the total time it takes from the initiation of a process or order until its completion, including any waiting or queue time.

In other words, lead time encompasses it but also includes additional time for activities such as order processing, material procurement, and transportation.

By understanding the difference between the both, businesses can identify opportunities to reduce both metrics and improve their overall operational performance.

Calculating Cycle Time

Accurately calculating cycle time is crucial for understanding and optimizing your manufacturing or operational processes. The formula is relatively straightforward:

Cycle Time = Operating Time / Number of Units Produced

Operating time refers to the total time the process was running to produce the units, including any minor stops or delays. This does not include significant downtime events like shift changes, maintenance, etc.

For example, if a machine ran for 7 hours and produced 350 units in that time, the cycle time would be:

Cycle Time = 7 hours x 60 minutes/hour = 420 minutes

420 minutes / 350 units = 1.2 minutes per unit

Calculating cycle times for each step of a multi-step process is important, as bottlenecks can occur at any point. The overall cycle time will be determined by the slowest operation.

For processes with significant variations, using an average calculation may not provide an accurate picture. In this case, tracking cycle times for each unit and analyzing the distribution can reveal more insights.

Some advanced calculation methods account for factors like:

- Non-Value Added Time (inspections, material handling, etc.)

- Simultaneous Cycle Times (for parallel operations)

- Shared Resources Between Products

Cycle time calculation (the formula) becomes more complex for re-entrant processes where units revisit the same operation multiple times. However, the core principle of operating time divided by throughput still applies.

Analyzing and Optimizing Cycle Time

Regularly analyzing this data is crucial for identifying bottlenecks and opportunities for improvement. There are several key metrics and methods used:

Cycle Time Analysis

Calculate it for each process step and the total. Look for steps with excessive cycle times that may constrain the entire process flow. Techniques like value stream mapping can provide more detailed insights.

Cycle Time Variation

Track how much cycle times vary from cycle to cycle and the distribution. Excessive variation often indicates inconsistent methods, material issues, equipment problems, etc. Reducing variation can optimize it.

Takt Time Comparison

Takt time is the maximum cycle time allowed to meet customer demand. Compare it to the takt time – if the cycle time exceeds the takt time, you cannot keep up with demand. This signals the need to reduce cycle times.

Benchmarking

Compare your cycle times to similar processes internally or industry benchmarks for the same products/processes. Large gaps indicate room for optimization.

Once problem areas are identified through analysis, there are many potential improvement techniques:

Mistake-Proofing

Implement poka-yoke methods to prevent defects and errors that require rework and increase cycle times.

Workspace Organization

Organize tools, materials, and the workspace (5S) for more efficient movements and material handling to reduce it.

Process Streamlining

Eliminate unnecessary steps, transportation, and waiting through techniques like continuous flow, cellular manufacturing, etc.

Automation

Automated equipment, machines, or processes can perform steps much faster than manual cycles.

Cycle Time Optimization

Applying lean tools like SMED, cycle time analysis, theory of constraints, and designed experiments can further optimize it.

Monitoring cycle times and continuously working to reduce them is key to improving process velocity and throughput.

The tight integration between cycle times and overall equipment effectiveness (OEE) means optimizing cycles directly impacts manufacturing productivity and profitability.

Cycle Time in Lean Manufacturing

Cycle time is a critical metric in lean manufacturing principles and practices. In a lean production system, the focus is on maximizing value for the customer while minimizing waste. It directly impacts manufacturing lead times, inventory levels, and overall productivity.

In lean terms, it refers to the total time required to complete one cycle of an operation from start to finish.

Organizations often encourage employees to obtain Six Sigma Green Belt certification to effectively implement these methodologies, ensuring alignment with lean principles like waste reduction and continuous flow.

This includes processing time as well as inspection, movement of materials, queuing delays, etc. Minimizing it allows manufacturers to produce only to customer demand, reducing excess inventory.

Some key lean tools and methodologies that relate to optimizing cycle time include:

Takt Time

Takt time is the maximum cycle time allowed to produce one piece to match the customer demand rate. Aligning it to takt time is essential for proper flow and avoiding overproduction.

Continuous Flow

Lean principles emphasize creating a continuous flow of production with minimal stoppages or queues between processes. Reduced cycle times enable this continuous flow.

Kanban Systems

Kanban replenishment signals work to replenish just what is consumed by the next operation, based on cycle times. Proper cycle time analysis is required to set kanban quantities.

Single Minute Exchange of Dies (SMED)

SMED aims to minimize changeover times between production runs. Quick changeovers enable smaller batch sizes and reduced cycle times.

Total Productive Maintenance (TPM)

Unplanned downtime from equipment failures increases cycle times. TPM practices maximize equipment uptime and availability.

Cycle Time Tracking and Reporting

Keeping track of cycle times across processes is crucial for identifying bottlenecks, inefficiencies, and opportunities for improvement. Many organizations use specialized tracking software and tools to monitor this key metric.

The tracking software allows you to automatically capture start and end times for each step of a process. This data is then aggregated to calculate the overall cycle time.

Visual reports and dashboards make it easy to analyze this, compare against targets, and spot trends over time.

Some key capabilities to look for in these tracking tools include:

Measurement

The ability to precisely measure it by triggering start/stop times based on system events, user input, or integrated with equipment/sensors. Ensuring accurate data is critical.

Monitoring

Real-time monitoring dashboards that allow you to watch these as processes occur. This enables quicker response if cycle times start trending longer than expected.

Reporting

Out-of-the-box and customizable reports analyze the performance across different dimensions like product type, work center, shift, etc. Historical trend reports are also valuable.

Benchmarking

The ability to benchmark cycle times against targets, theoretical minimums, past performance windows, and industry benchmarks. This helps you understand how your operations measure up.

Analysis

Root cause analysis capabilities allow you to drill into the data and pinpoint reasons for delays, deviations, and extended cycle times at a granular level.

By leveraging specialized tracking and reporting tools, you gain far better visibility into its performance. This data-driven insight allows you to manage and optimize this key metric more effectively.

Specialized training, such as root cause analysis training, empowers teams to systematically address delays identified through cycle time tracking.

Cycle Time in Project Management

In addition to manufacturing, this concept is also critical in project management. Cycle time measures the amount of time it takes to complete one process or task from start to finish within a project workflow.

Tracking cycle times allows teams to identify bottlenecks, optimize processes, and deliver projects faster.

For software development projects following Agile methodologies like Scrum, this refers to the total time elapsed between when a task or user story is started and when it is considered complete and potentially shippable. Monitoring cycle times helps Agile teams inspect and adapt their processes to maximize efficiency.

Similarly, in project management frameworks like Kanban, it measures how long it takes for a task or work item to transit through all stages of the project workflow from initial request to final delivery.

Keeping cycle times short and predictable is key to maintaining a continuous flow of value delivery.

Strategies to Reduce Cycle Time in Projects:

- Eliminate handoffs and task switching between team members

- Break down large work items into smaller, more granular tasks

- Implement work-in-progress (WIP) limits to prevent bottlenecks

- Automate testing, builds, and other repeatable processes

- Foster collaboration and quick feedback loops

- Measure it consistently and optimize iteratively

By focusing on reducing it, project teams can increase throughput, improve time-to-market, and deliver more value to customers faster.

It is an essential lean metric for any organization aiming to boost productivity and efficiency across their project portfolios.

Parting Notes

Cycle time is a critical metric for any organization looking to improve efficiency, productivity, and profitability. By understanding it and how to calculate, analyze, and optimize it, businesses can identify bottlenecks, streamline processes, and gain a competitive edge.

In manufacturing environments, minimizing it is essential for reducing inventory costs, increasing throughput, and meeting customer demand.

Professionals seeking to master these techniques often pursue Six Sigma certification, which provides comprehensive training in process optimization, statistical analysis, and waste reduction strategies.

For project management and software development teams, monitoring and minimizing it leads to faster delivery, improved quality, and better resource utilization. Agile frameworks emphasize the importance of optimizing it to drive continuous improvement.

Regardless of industry, organizations should make this measurement, tracking, and optimization an ongoing priority.

By embracing best practices, implementing cycle time management software, and fostering a culture of continuous improvement, companies can unlock new levels of performance and efficiency.

Ultimately, mastering cycle time requires a holistic approach that considers people, processes, and technology. With the right strategies in place, any organization can reap the substantial benefits of optimized cycle times and gain a formidable competitive advantage.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs