Lean Fundamentals

Lean Fundamentals program provides candidates with a thorough working knowledge of the principles of Lean

6Sigma.us’ Lean Fundamentals course introduces the principles of Lean and the overall importance of focusing on what adds value to the customer. Lean Fundamentals provides individuals methods to recognize wastes in processes as well as identify barriers to flow and implement pull in their current processes.

Course Outline – Lean Fundamentals

6Sigma.us offers Classroom and Virtual Instructor-led classes as well as Online Self-Paced training & certification programs.

Our Lean Fundamentals course covers the following topics:

- Lean Concepts and Lean Six Sigma

- Principles of Lean and A3 Thinking

- Project Planning and Approach

- Foundation of Lean: Waste

- Foundation of Lean: 5S

- Define Value

- Map the Value Stream

- Process Measures and Data Display

- Root Cause Analysis

- Create Flow

- Establish Pull

- Mistake Proofing

- Pursue Perfection

- Ideal and Future State Maps

- Lean Six Sigma

- Wrap-Up

Online Self-Paced Training

Start with online training!

Virtual Instructor-led Training

See the schedule for upcoming classes!

At the end of this course, the attendees will:

- Recognize that Lean and Six Sigma are very compatible systems that function more effectively as a cohesive unit. 6Sigma.us provides a complete range of Lean and Six Sigma classes, as well as deployment assistance.

- Gain the skills necessary to utilize Lean methodologies that reduce cycle times, and improve productivity and quality.

- Establish robust Value Stream Maps for any process.

There are no prerequisites for the Lean Fundamentals program. Lean Introduction concepts are covered during this training.

Attendees will receive two certificates, one certificate for successfully completing the training and another certificate for successfully completing a live project, which will designate individuals as internationally-recognized Lean Agents. Coaching is provided by 6Sigma.us instructors. Typical projects can be completed in 4-12 weeks.

As an IACET, PMI, and SHRM Accredited Provider, 6Sigma.us offers IACET CEUs, PMI PDUs, and SHRM PDCs for its learning events. (PMI and the PMI Registered Education Provider logo are registered marks of the Project Management Institute, Inc.).

What is Lean? Understanding the Fundamentals

Lean methodology, at its core, is a systematic approach to eliminating waste and maximizing value in any process. It’s more than just a set of tools – it’s a philosophy that can revolutionize how we think about efficiency and value creation.

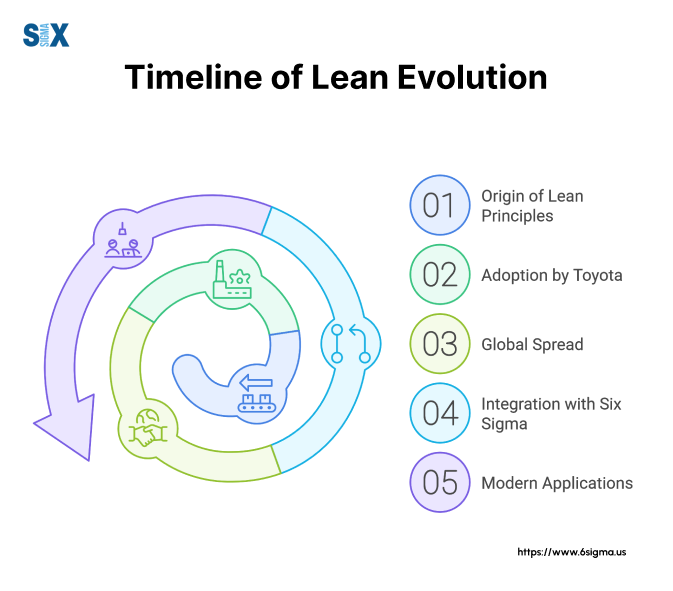

The roots of lean trace back to the Toyota Production System (TPS) developed in Japan after World War II. Taiichi Ohno, often considered the father of TPS, developed this system to compete with more resource-rich American car manufacturers.

The goal was simple yet profound: produce high-quality vehicles more efficiently by eliminating waste in every step of the production process.

The Evolution of Lean: From Manufacturing to Service Industries

While lean principles originated in manufacturing, we’ve had the privilege of applying these concepts across a wide range of industries. From healthcare to software development, and even government institutions.

Lean concepts can be adapted to improve service delivery and customer satisfaction. The key is to understand that waste isn’t just physical – it can be found in processes, waiting times, and even in how information flows through an organization.

Core Principles of Lean Methodology

Understanding and applying the five core principles of lean is crucial for any successful implementation:

- Identify Value: Define what creates value from the customer’s perspective.

- Map the Value Stream: Identify all steps in the value stream, eliminating those that don’t create value.

- Create Flow: Ensure that the value-creating steps occur in a tight sequence.

- Establish Pull: Only make what is pulled by the customer just-in-time.

- Seek Perfection: Strive for continuous improvement.

These principles form the backbone of any lean initiative, whether you’re optimizing a production line or streamlining a business process.

The Lean Mindset: Shifting Perspectives for Success

The most crucial aspect of Lean is cultivating the right mindset. It’s about seeing waste where others see normal processes, and constantly asking, “How can we do this better?”

This shift in perspective is what we focus on in our lean fundamentals training courses. It’s not just about learning lean techniques; it’s about developing a keen eye for improvement opportunities and fostering a culture of continuous learning.

The 8 Wastes in Lean: Identifying and Eliminating Inefficiencies

Countless organizations struggle with inefficiencies that drain resources and hinder growth. The key to unlocking true potential lies in understanding and eliminating what we in the lean world call “Muda” or waste.

This concept is at the heart of lean practices and is crucial for anyone looking to master lean fundamentals.

What are the 8 Wastes in Lean?

- Defects: Errors or mistakes that require rework.

- Overproduction: Producing more than is needed or before it’s needed.

- Waiting: Idle time where no value is being added.

- Non-Utilized Talent: Underutilizing people’s skills and knowledge.

- Transportation: Unnecessary movement of products or materials.

- Inventory: Excess products or materials not being processed.

- Motion: Unnecessary movement by people.

- Extra-Processing: Doing more work than necessary to produce the product.

Understanding these wastes is crucial for anyone pursuing lean fundamentals certification or implementing lean techniques in their organization.

Strategies for Identifying Hidden Wastes in Your Organization

Here are some strategies crucial in mastering lean fundamentals:

- Gemba Walks: Regularly observe processes firsthand to spot inefficiencies.

- Value Stream Mapping: Visualize your entire process to identify non-value-adding steps.

- 5 Whys Analysis: Dig deep to find the root causes of waste.

- Employee Involvement: Encourage staff to report wastes they encounter daily.

- Metrics and KPIs: Use data to track and identify areas of waste.

The goal of lean is continuous improvement. Even after implementing these strategies, always be on the lookout for new forms of waste.

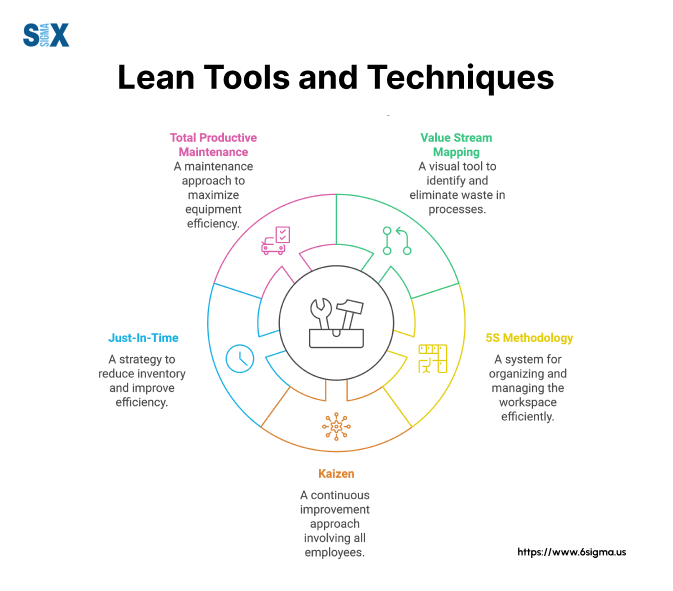

The right lean tools and techniques can revolutionize business processes. Here are some essential lean tools that form the backbone of any successful lean implementation.

Value Stream Mapping: Visualizing Your Processes

Value Stream Mapping (VSM) is one of the most powerful lean techniques. It’s a visual tool that helps you see the flow of materials and information as a product or service moves through your value stream.

Key elements of successful VSM implementation include:

- Identify the product family

- Draw the current state map

- Analyze the map to identify waste

- Create a future state map

- Develop an action plan to achieve the future state

5S: Organizing for Efficiency

5S is a lean method which is a simple yet powerful tool for organizing the workplace.

Key elements of successful 5S implementation include:

- Sort (Seiri): Remove unnecessary items

- Set in Order (Seiton): Organize remaining items

- Shine (Seiso): Clean and inspect the work area

- Standardize (Seiketsu): Establish standards for the first three S’s

- Sustain (Shitsuke): Maintain and review standards

Kaizen: Fostering Continuous Improvement

Kaizen, meaning “change for better” in Japanese, is at the heart of lean methodology. It’s not just a tool, but a philosophy of continuous improvement that involves everyone in the organization.

Key elements of successful Kaizen implementation include:

- Encouraging employee involvement at all levels

- Focusing on small, achievable improvements

- Celebrating successes, no matter how small

- Creating a culture of continuous learning

Lean Six Sigma: Complementing Lean for Quality Control

While not strictly a lean tool, Six Sigma complements lean practices, forming what we call Lean Six Sigma.

Six Sigma focuses on reducing variation and improving quality, which aligns perfectly with lean’s goal of eliminating waste.

Key benefits of integrating Six Sigma with lean include:

- Data-driven decision making

- Structured problem-solving approach

- Focus on both efficiency (lean) and quality (Six Sigma)

If you’re wondering, “Which tool should I start with?” The answer depends on your organization’s specific needs and challenges. Here are some guidelines:

- For process improvement: Start with Value Stream Mapping

- For workplace organization: Begin with 5S

- For workflow management: Implement Kanban

- For cultural change: Focus on Kaizen

- For complex quality issues: Consider integrating Six Sigma

Remember, lean is not about blindly applying tools, but about understanding your processes and continuously striving for improvement. These tools are means to an end, not the end itself.

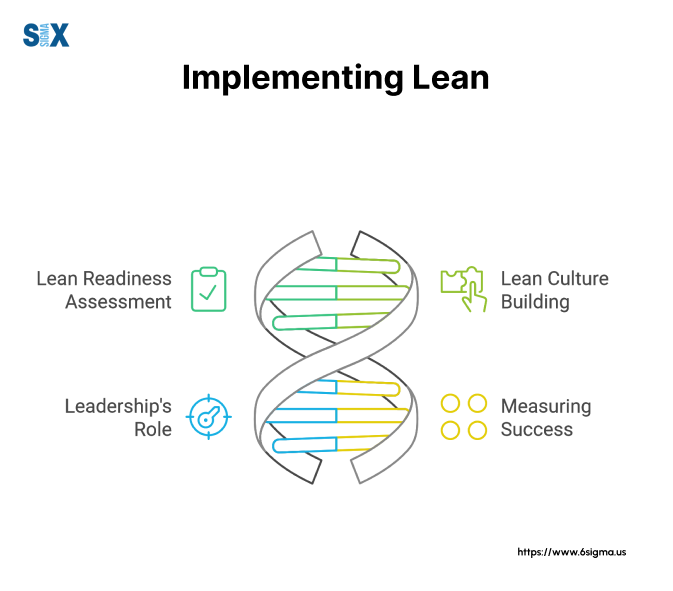

Implementing Lean: A Roadmap to Success

Implementing lean fundamentals is as much about cultural change as it is about process improvement.

Assessing Your Organization’s Lean Readiness

Before diving into lean implementation, it’s crucial to assess your organization’s readiness.

Key areas to evaluate include:

- Leadership commitment: Is top management fully on board?

- Employee engagement: Are staff open to change and continuous improvement?

- Current processes: How well-documented and standardized are your processes?

- Data availability: Do you have the necessary data to make informed decisions?

- Resource allocation: Are you prepared to invest time and resources in lean initiatives?

Building a Lean Culture: Overcoming Resistance to Change

Implementing lean methodology is as much about changing mindsets as it is about changing processes. Resistance to change is the biggest hurdle in lean transformation.

Strategies effective in building a lean culture include:

- Communication: Clearly articulate the benefits of lean to all stakeholders.

- Education: Provide comprehensive lean fundamentals training at all levels.

- Early wins: Start with small, high-impact projects to build momentum.

- Recognition: Celebrate successes and reward lean behaviors.

- Involvement: Engage employees in problem-solving and continuous improvement efforts.

Leadership commitment is non-negotiable in lean implementation. Leaders must not only support lean initiatives but actively participate in them.

Key leadership responsibilities in lean transformation include:

- Setting the vision: Clearly define what lean means for your organization.

- Allocating resources: Ensure teams have the time and tools they need.

- Leading by example: Participate in lean activities and demonstrate lean behaviors.

- Removing barriers: Address organizational obstacles to lean implementation.

- Sustaining momentum: Keep the organization focused on long-term lean goals.

Measuring Lean Success: KPIs and Metrics

In a lean implementation, choosing the right Key Performance Indicators (KPIs) is crucial for tracking progress and maintaining momentum.

Some essential lean metrics I recommend include:

- Lead Time: Time from order to delivery

- Cycle Time: Time to complete a process

- First Pass Yield: Percentage of units produced correctly the first time

- Overall Equipment Effectiveness (OEE): Measure of manufacturing productivity

- Employee Engagement: Often measured through surveys or participation in improvement activities

“Lean is not a destination, but a journey of continuous improvement. The key to success is to start small, think big, and scale fast.”

Peter Peterka, Master Black belt & President, SixSigma.us

Lean Fundamentals Training & Certification Process

Now, let’s dive into the Lean Fundamentals certification process.

Training Options

When it comes to Lean Fundamentals training, you have several options:

- In-Person Training: If you prefer a traditional classroom setting, this training option is for you. We conduct numerous in-person training sessions. Check out our current training schedule.

- Virtual Instructor-led: For those who prefer live training, but from the convenience of your office or home, this is the go-to option. The best part, you learn via an interactive seminar with other professionals, taught by certified Master Black Belt. Check out our current training schedule.

- Live Private Training: if you are looking to train multiple employees, we can also deliver at your site or private virtual. Contact us for more information.

- Online Courses: We offer comprehensive online courses that allow you access 24/7 to learn at your own pace. This flexibility is perfect if you have a busy schedule. Check out our course.

Stay ahead of the curve and drive value in your organization as a certified Lean professional.

Start your Lean Fundamentals training & certification today!

-

The instructor, Juan Aragon, has vast industry experience and the stories help to connect how Lean practice was applied and the common problems out there. It made the class more interesting.

Josephyne Quach |

5

-

Personable and knowledgeable instructor, took time to answer questions and tried to get class to use relevant situations.

John Crowley |

5

-

Jaqlyn was very informative and eager to help. Very knowledgeable and what she was delivering. Enjoyed the week.

Cory Boyd |

5

-

Jaclyn kept the material relatable and had many relevant examples to help the group grasp the material. I really liked the spaghetti diagram exercise with making tea as well as the other group activities that asked us to work through live problems.

Jessie Hoff |

5

-

I was overly excited about the course material, but Jaclyn did very well to explain and relate it back to the industry I worked in.

Andres Jimenez |

5

-

Excellent instructor. She was very easy to study under and showed a great interest in ensuring we were comfortable in our understanding of the lessons. I left feeling very positive and encouraged to take the knowledge and apply it at my job.

Brett Dennis |

5

-

Practical examples and discussions on how we may be able to implement these in our facilities.

Lisa Campbell |

5

-

Hearing others issues and examples of how this course applies directly to them.

Lynne Goldman |

5

-

I really enjoyed the examples from the hospital setting and the interactive pieces of the class which helped to keep me engaged.

Olivia Dan |

5

-

I liked the practical application component to the class. I left with a lot of great ideas, but now the issue is getting them off the ground!

Larissa Cupp |

5

Training Schedule

Lean Fundamentals

[

]

Lean Fundamentals

[

]

Lean Fundamentals

[

]

Lean Fundamentals

[

]