Plan Do Study Act Cycle for Lean Six Sigma & Continuous Improvement

Making process changes that actually stick presents a significant challenge, particularly within the complex systems common in Lean Six Sigma and other operational environments.

How can organizations ensure that improvements lead to sustained gains rather than fading over time?

A proven method involves adopting a structured, iterative approach.

The plan do study act cycle provides a foundational framework designed specifically for learning and making refinements through repeated application.

This guide examines the pdsa cycle in detail, explaining how this valuable tool fosters effective quality improvement.

Key Highlights

- What is the PDSA cycle?

- Exploring the four key stages

- Comparing PDSA and other models

- Practical examples and useful tools

- How to avoid common pitfalls

What Exactly Is The Plan-Do-Study-Act Cycle?

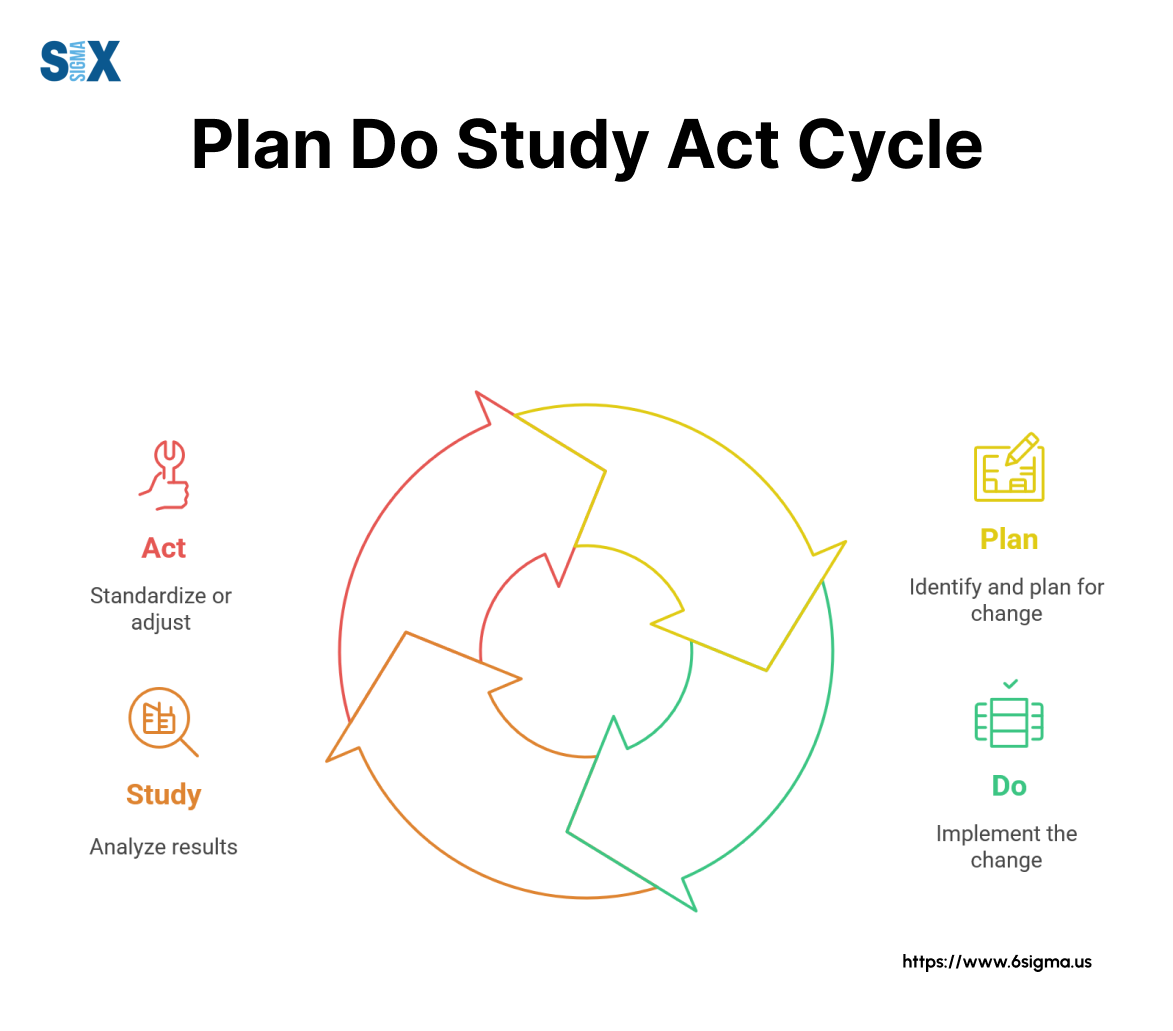

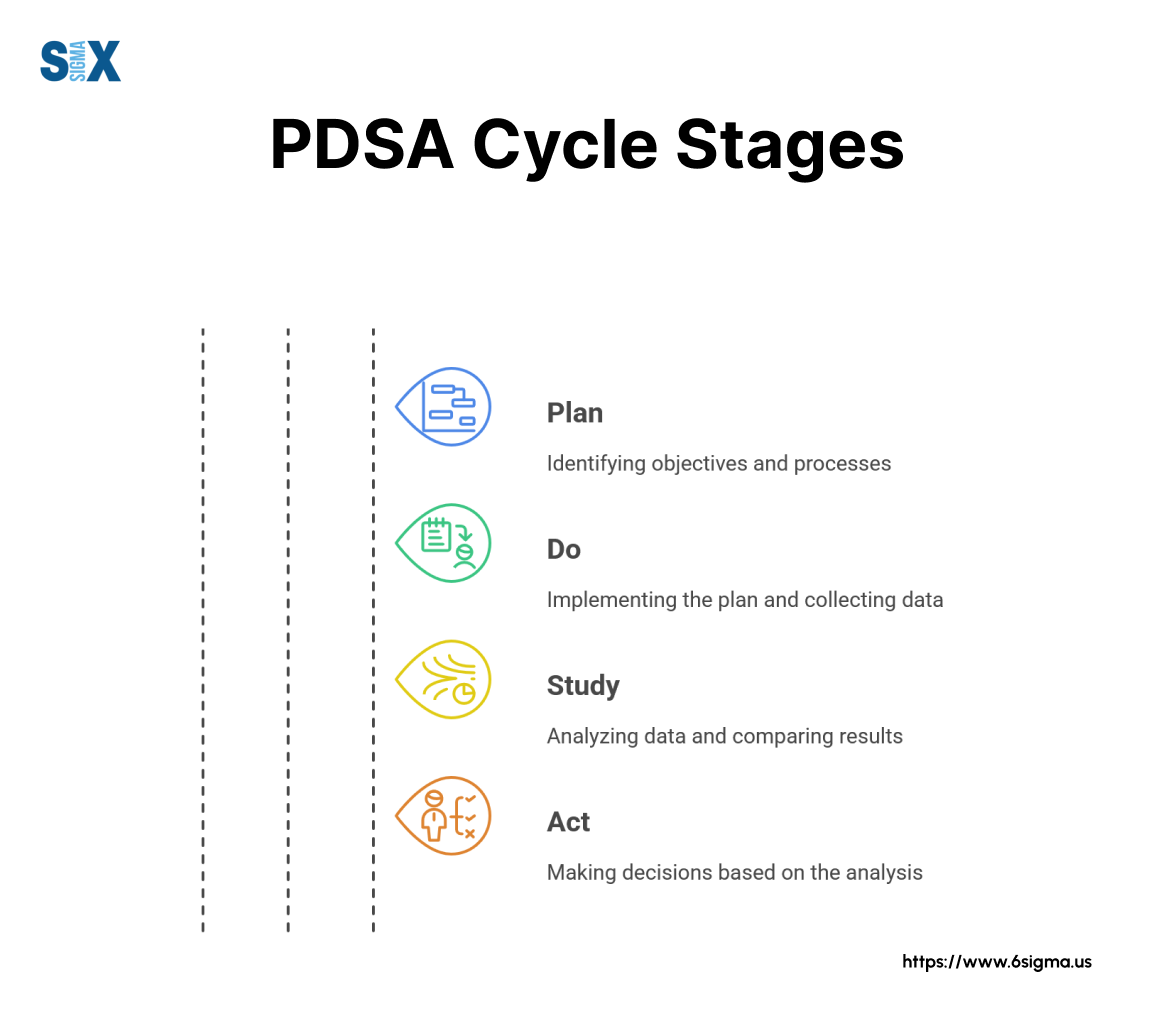

The Plan-Do-Study-Act (PDSA) cycle is a structured, four-stage iterative method used for problem-solving and enacting process improvements. It serves as a systematic approach to test changes and learn from their effects.

So, what does PDSA stand for? It represents the four key phases: Plan, Do, Study, and Act. The fundamental aim of the PDSA cycle is to foster continuous learning and refinement.

Rather than implementing large, untested changes, this pdsa cycle model encourages making incremental adjustments, studying their impact, and building upon that knowledge.

The Origins: Understanding Deming’s And Shewhart’s Legacy

The roots of this powerful improvement tool trace back to the renowned statistician Dr. Walter A. Shewhart.

In the 1920s and 30s, while working at Bell Labs, Shewhart introduced a concept for quality control based on a cycle of specification, production, and inspection – often referred to as the Shewhart cycle or Plan-Do-Check-Act (PDCA).

However, it was Dr. W. Edwards Deming, a student and mentee of Shewhart, who significantly refined and popularized the methodology in the 1950s, particularly during his work in post-war Japan.

Deming adapted Shewhart’s model, transforming it into what is now widely known as Deming’s PDSA cycle.

A key modification was changing “Check” to “Study.” Deming emphasized that “Study” implies a deeper analysis and learning from the results compared to the simpler verification suggested by “Check.”

This focus on learning makes the pdsa cycle a cornerstone of modern continuous improvement philosophy.

While Shewhart laid the groundwork, Deming is largely credited with shaping the plan do study act cycle into the widely adopted format used today.

Deconstructing The Plan Do Study Act Cycle: The 4 Stages Of PDSA Explained

The effectiveness of the plan do study act cycle lies in its structured progression through four distinct phases.

Understanding each of these stages of the pdsa model is essential for successful implementation.

Let’s examine the four steps of the pdsa cycle:

Stage 1: PLAN – Charting The Course For Change

This initial stage is foundational; a well-executed pdsa plan significantly increases the likelihood of a successful cycle. It begins with identifying an opportunity for improvement or a problem to solve.

This involves analyzing the current process or situation to understand its performance and limitations. Based on this understanding, specific objectives for the improvement effort are set.

Utilizing SMART goals in pdsa cycle planning (Specific, Measurable, Achievable, Relevant, Time-bound) brings clarity and focus.

A crucial part of the pdsa project plan is formulating a theory or hypothesis about what change will lead to the desired improvement.

Finally, a detailed plan for testing this change is developed, outlining:

- What specific change will be tested?

- Who will be involved in carrying out the test?

- When and where will the test occur?

- What data needs to be collected to evaluate the change’s impact?

- How will the data be collected?

Careful consideration during this phase prevents wasted effort later. Ask your team: What specific, measurable goal are you trying to achieve with this plan study do act cycle?

Stage 2: DO – Executing The Test And Gathering Data

With the plan in place, the next stage involves carrying out the proposed change or test. Importantly, this is typically done on a small scale first to minimize disruption and risk.

During the “Do” phase, careful observation is critical. Team members document activities, note any deviations from the plan, and record observations about how the change is working – including both expected outcomes and unexpected effects.

Systematic data collection, following the methods defined in the “Plan” stage, is essential for the objective analysis that follows.

Remember to document problems and unexpected observations – they are often valuable learning opportunities within the plan do study act cycle.

Stage 3: STUDY – Analyzing Results And Extracting Insights

This phase is central to the learning aspect of the plan study do act cycle, marking the key difference from simpler check routines.

The data collected during the “Do” stage is now analyzed thoroughly. Results are compared against the baseline data gathered before the change and against the predictions made in the hypothesis during the “Plan” stage.

The goal is to understand the impact of the tested change. Did it lead to the desired improvement? Were there unintended consequences?

What insights were gained, regardless of whether the test was deemed a success or failure? Basic analysis tools like run charts or Pareto charts can be helpful here.

The emphasis is on deep study to extract meaningful learning. Reflect on the data: Did the results match your prediction? Why or why not? What did you learn?

Stage 4: ACT – Standardizing Success Or Planning The Next Cycle

The final stage involves taking action based on the insights gained during the “Study” phase. There are typically three paths forward in the plan act study do sequence:

- Adopt: If the change proved successful and led to the desired improvement, the team works to standardize it. This involves updating procedures, providing training, and integrating the change into normal operations.

- Adapt: If the change showed promise but didn’t fully meet objectives, or if the study revealed ways to improve it, the plan is modified. Learnings are incorporated, and the team returns to the “Plan” stage to initiate another cycle, refining the approach.

- Abandon: If the tested change proved ineffective or had negative consequences, the approach is discarded. However, the learnings from the failed test are still valuable and inform future planning as the team returns to the “Plan” stage, potentially with a completely new hypothesis.

This act plan study do conclusion ensures that learning translates into concrete next steps, driving the continuous nature of the plan do study act cycle.

Determine your path: Based on your ‘Study’ findings, what is your concrete next step: Adopt, Adapt, or Abandon?

Explore Yellow Belt Training & Certification

Take the next step to actively contribute to improvement projects and apply these concepts effectively.

Plan Do Study Act (PDSA) Cycle Vs. The Field: How It Compares To Other Improvement Models

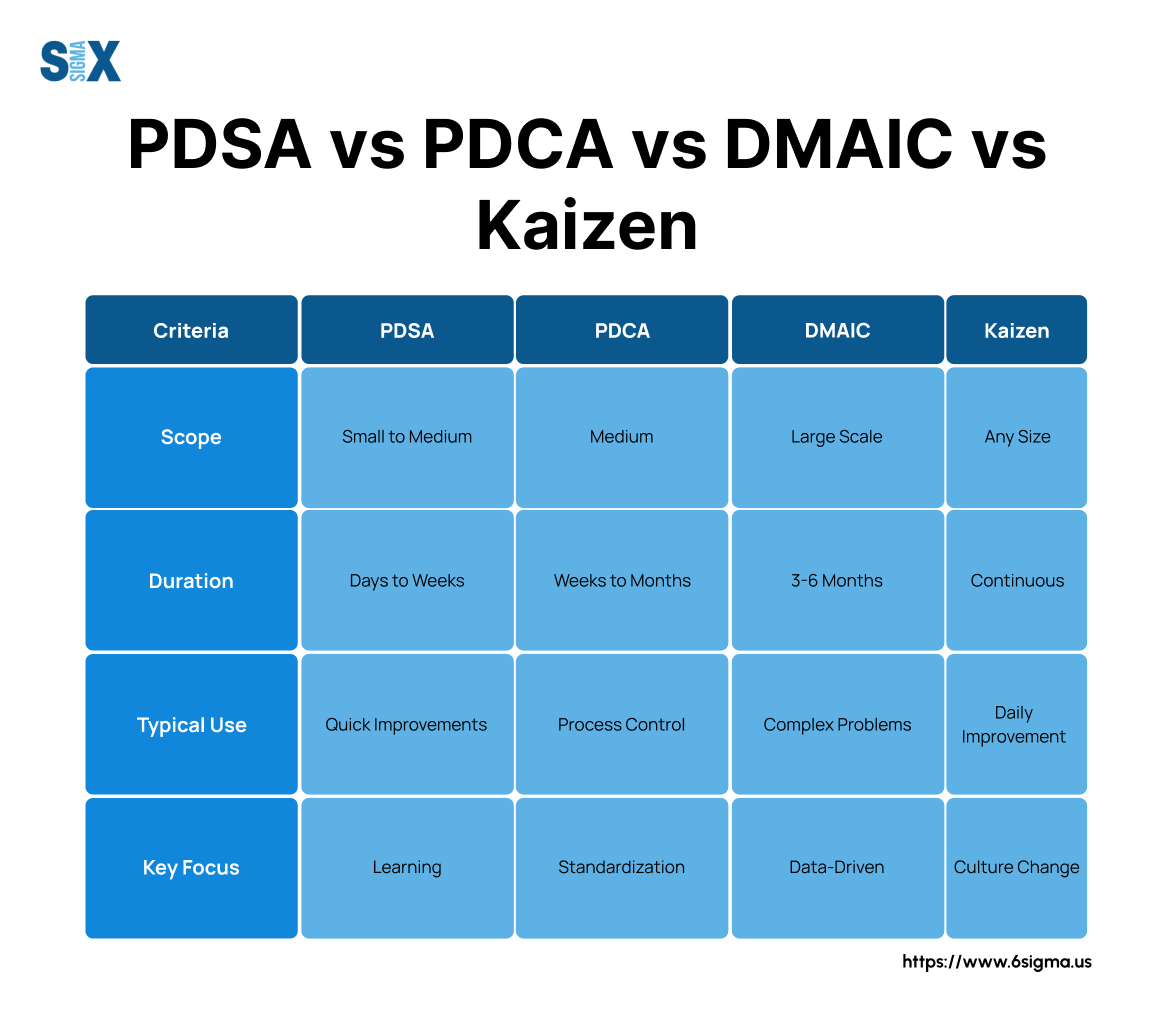

The plan do study act cycle is a powerful tool, but it exists alongside other well-known methodologies for process improvement.

PDSA Vs. PDCA: Why “Study” Matters More Than “Check”

Often, PDSA is confused with its predecessor, PDCA (Plan-Do-Check-Act). While similar, the key difference lies in the third step.

As mentioned earlier, Dr. Deming deliberately changed “Check” to “Study.” “Check” often implies a simple verification – did the change happen as planned, yes or no?

“Study,” however, promotes a deeper level of analysis and learning. It encourages teams to compare the results to predictions, understand why the results occurred (whether expected or unexpected), and revise the underlying theory or hypothesis about the process.

Deming believed this emphasis on learning and theory refinement was crucial for driving meaningful, sustainable improvement, distinguishing the rigorous intent of PDSA from a potentially superficial PDCA check.

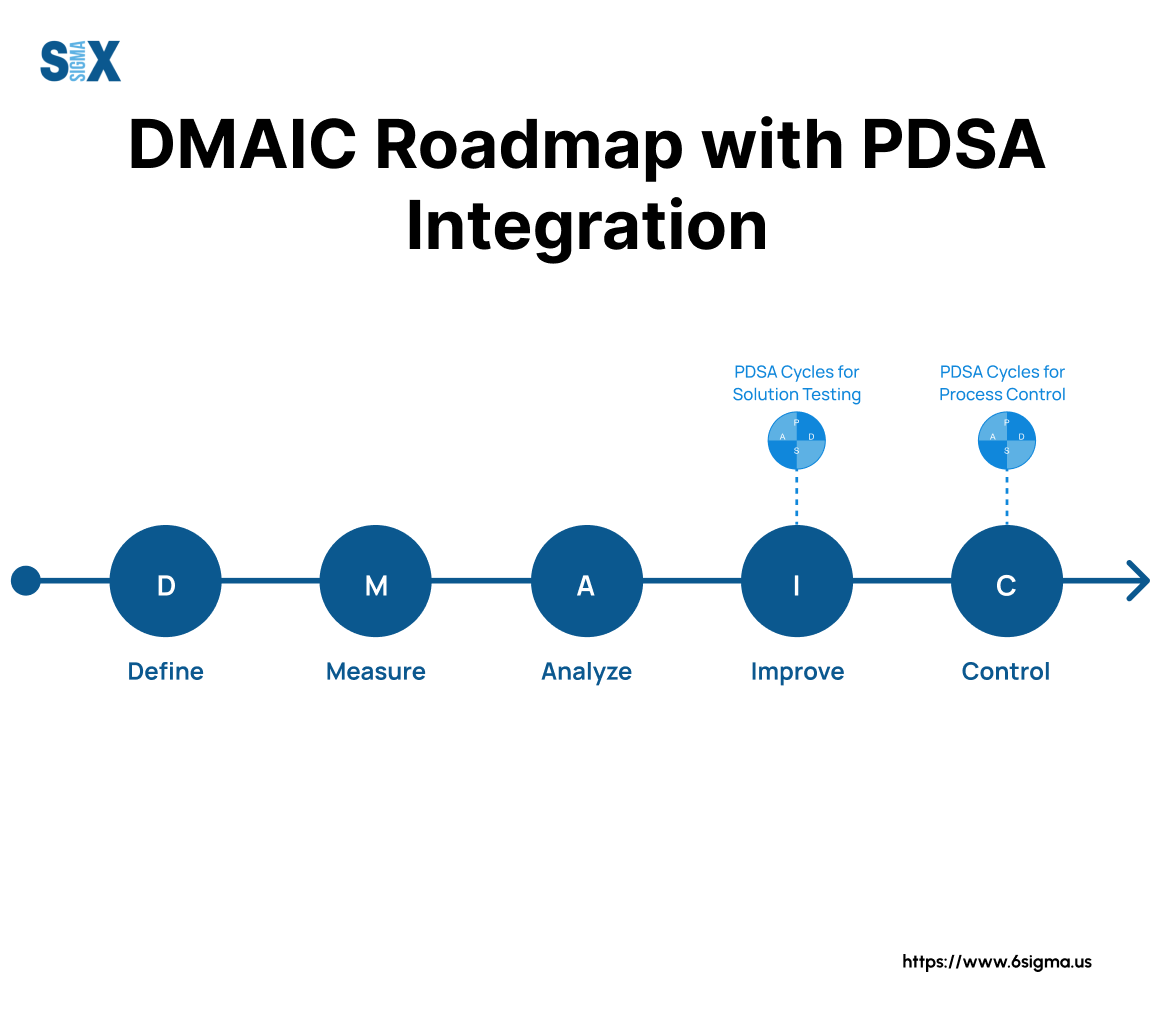

Plan Do Study Act Cycle Vs. DMAIC: Iterative Cycles Within A Larger Framework

DMAIC (Define, Measure, Analyze, Improve, Control) is the structured problem-solving methodology central to Six Sigma.

It’s typically used for larger, more complex projects requiring extensive data analysis. How does PDSA relate? Instead of being mutually exclusive, they are often complementary.

PDSA cycle quality improvement efforts are frequently employed within the Improve phase of DMAIC to test potential solutions identified during the Analyze phase. They can also be used in the Control phase to make small adjustments and ensure improvements are sustained.

Furthermore, PDSA cycles are ideal for tackling smaller improvement opportunities that may not warrant a full DMAIC project.

Asking “Why is PDSA better than DMAIC?” misses the point; they operate at different scales. DMAIC provides the overarching project structure, while PDSA offers a mechanism for iterative testing and learning within or alongside that structure.

PDSA Vs. Kaizen: Continuous Cycles Vs. Improvement Events/Philosophy

Kaizen, a Japanese term meaning “change for the better” or “continuous improvement,” represents both a broad philosophy and specific, focused improvement events (often called Kaizen events or blitzes).

The philosophy encourages everyone in an organization to constantly look for small improvements in their work. Kaizen events are typically short, intense workshops focused on rapidly improving a specific process area.

What is the difference between PDSA and Kaizen? While both aim for improvement, PDSA provides a specific, repeatable four-step cycle for testing changes scientifically.

Kaizen is the overarching philosophy, and while Kaizen events might use PDSA thinking within them, PDSA itself is the structured experimental loop. The pdsa cycle of improvement is a tool that supports the broader Kaizen philosophy.

Key Strengths And Benefits Of The Plan Do Study Act Cycle

Adopting the plan do study act cycle brings distinct advantages to organizations seeking structured ways to improve.

Why Implement Plan Do Study Act Cycle? Top Advantages

Several core strengths of pdsa cycle contribute to its enduring relevance. Firstly, it promotes structured thinking, guiding teams through a logical sequence for testing changes.

Secondly, the pdsa cycle inherently encourages data-driven decisions by emphasizing measurement and analysis in the “Do” and “Study” phases, moving beyond guesswork.

Thirdly, it facilitates iterative learning; the cyclical nature allows teams to build knowledge incrementally and adapt their approach based on real results.

Finally, the collaborative nature often fosters better teamwork and engagement as staff work together through the cycle. These combined pdsa cycle advantages make it a robust framework.

Ideal Scenarios For Applying Plan Do Study Act (PDSA) Cycle

The pdsa model for improvement proves particularly effective in specific situations. It is ideal when testing a proposed change or solution before full-scale implementation, allowing for validation and refinement.

When developing and implementing entirely new processes or workflows, the plan do study act cycle provides a structured way to pilot and adjust them.

Naturally, it is fundamental for driving ongoing continuous improvement initiatives, forming the engine for many quality programs. Its principles strongly support broader management systems, making the pdsa cycle in tqm (Total Quality Management) a common and effective application.

Consider your organization’s current initiatives: Which of these benefits would be most valuable for your current challenges?

Plan Do Study Act Cycle’s Crucial Role In The Lean Six Sigma Toolkit

Within the structured world of Lean Six Sigma (LSS), the plan do study act cycle serves as a vital and versatile tool.

Integrating Plan Do Study Act Cycle Within The DMAIC Framework

A common question arises: How are Six Sigma and PDSA interrelated? Is PDSA part of Six Sigma?

The answer is nuanced. While not a formal phase of DMAIC itself, PDSA cycles are frequently integrated within the DMAIC process.

Specifically, during the Improve phase, after potential solutions have been identified in the Analyze phase, teams often use PDSA cycles to pilot these solutions on a small scale.

This allows them to test the effectiveness of a proposed change, gather data, and refine the solution before a full rollout.

Similarly, in the Control phase, PDSA cycles can be used to verify that implemented changes are holding gains and to test small adjustments needed to maintain stability or further optimize the improved process.

Therefore, PDSA acts as a mechanism for iterative testing and refinement that supports the larger DMAIC structure in Lean Six Sigma.

Leveraging PDSA For Rapid Improvement Cycles In LSS

Beyond its integration with large DMAIC projects, the plan do study act cycle is invaluable in a Lean Six Sigma culture for driving smaller, more rapid improvements.

Not every opportunity requires the rigor of a full DMAIC project.

Teams can use PDSA cycles as a standalone method to quickly test ideas, address localized problems, or implement incremental enhancements identified through daily work or value stream mapping.

This allows for quick wins, fosters a culture of continuous experimentation and learning, and empowers teams to make ongoing refinements outside the scope of major projects, reinforcing the core principles of Lean Six Sigma.

Putting Theory Into Practice: PDSA Examples And Tools

Understanding the stages of the plan do study act cycle is the first step; seeing how it works in real-world scenarios and knowing which tools can help brings the methodology to life.

Plan Do Study Act Cycle Examples Across Diverse Fields

The versatility of the plan do study act cycle is one of its greatest strengths. It is not limited to manufacturing or quality control departments.

Here are several examples of pdsa applied across different sectors:

- Manufacturing: A team aims to reduce defect rates on a specific assembly line.

- Healthcare: A clinic wants to improve patient appointment scheduling time and reduce waiting.

- Software Development: An agile team wants to improve the efficiency of their new feature rollout process.

- Education: A teacher wants to refine a specific teaching method for a challenging topic based on student understanding.

- Small Business: A small e-commerce business aims to improve customer order fulfillment accuracy.

- Personal Productivity: An individual wants to experiment with time management techniques to increase focus.

These varied pdsa cycle examples illustrate how the fundamental plan do study act cycle can be adapted to nearly any situation requiring structured improvement.

Essential Tools To Support Your PDSA Efforts

While the plan do study act cycle is conceptually simple, certain tools can enhance its effectiveness during different stages:

- Plan: Brainstorming techniques (for identifying problems/solutions), Flowcharts (to map current processes), Affinity Diagrams (to organize ideas), Stakeholder Analysis.

- Do: Check Sheets (for simple data tallying), Data Collection Forms (for more detailed, structured data gathering), Observation Sheets.

- Study: Run Charts (to track data over time), Pareto Charts (to identify significant factors), Histograms (to understand data distribution), Basic Statistical Analysis.

- Act: Control Plans (to document standardized processes), Standard Work documents or Standard Operating Procedures (SOPs), Training materials.

Using appropriate tools adds rigor and clarity to each step.

Master Minitab to create meaningful charts and perform the essential data analysis required for successful PDSA Cycle

Implementation Considerations

Successfully applying the plan do study act cycle involves more than just knowing the steps; certain considerations during implementation can significantly impact outcomes.

Setting SMART Goals For Effective Plan Do Study Act (PDSA) Cycles

The clarity of your objective, defined in the “Plan” stage, is paramount. Utilizing the SMART criteria helps ensure focus and measurability throughout the plan do study act cycle.

What are SMART goals in PDSA cycle planning? They are goals that are Specific (clearly defined), Measurable (quantifiable), Achievable (realistic), Relevant (aligned with broader objectives), and Time-bound (having a defined timeframe).

For instance, instead of aiming to “improve customer satisfaction,” a SMART goal might be: “Reduce customer complaint resolution time by 15% (from an average of 48 hours to 41 hours) within the next three months by implementing a new follow-up procedure (the tested change).

This level of specificity makes planning, measurement, and evaluation much more effective.

Determining The Right Cycle Duration

A common question is: How long should a PDSA cycle last? There isn’t a single fixed answer, as the ideal duration depends on the complexity of the problem, the scope of the change being tested, and the context.

However, a key principle of the plan do study act cycle is rapid learning. Where possible, aim for shorter cycles (days or weeks rather than months) to accelerate feedback and adaptation.

Overly long cycles can delay learning, cause the project to lose momentum, and increase the risk associated with the test. Balance the need for sufficient time to collect meaningful data with the imperative to iterate quickly.

Scaling Plan Do Study Act Cycle: From Micro-Experiments To Macro-Changes

The power of the plan do study act cycle extends beyond single, isolated improvements.

Learnings gained from small-scale, focused PDSA cycles can provide valuable data and insights that inform larger-scale implementations or even strategic shifts.

Successful micro-experiments build confidence and evidence for broader rollouts.

Frequently Asked Questions (FAQs) About The PDSA Cycle

Here are answers to some common questions about the plan do study act cycle:

A. The primary difference lies in the third step: PDSA uses “Study” while PDCA uses “Check.” “Study” implies a deeper analysis of results compared to predictions, focusing on learning why something happened and revising theories.

“Check” often signifies a simpler verification of whether the plan was followed or the immediate goal met. PDSA emphasizes learning as the core driver of improvement.

A. Absolutely. While widely used in those sectors, the plan do study act cycle is a versatile framework applicable anywhere structured improvement is needed.

Examples include software development (testing features or processes), education (refining teaching methods), small business operations (improving customer service), marketing (testing campaign elements), and even personal productivity. Its principles are industry-agnostic.

A. Conceptually, the plan do study act cycle is straightforward. The four stages are logical and easy to understand.

The complexity arises in the execution. Implementing PDSA effectively requires discipline: thorough planning, careful data collection, rigorous analysis during the “Study” phase, and commitment to taking action based on the findings in the “Act” stage.

Skipping steps or performing them superficially reduces its effectiveness.

A. All four stages of the plan do study act cycle are interconnected and necessary for the cycle to function properly.

Neglecting any stage weakens the process. However, arguably the “Study” and “Act” stages are where the value is truly realized.

Study is where learning occurs, and Act is where that learning is translated into tangible improvement or informed decisions for the next cycle.

Without effective Study and Act phases, the Planning and Doing may not lead to meaningful progress.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs