Lean Six Sigma in Project Management. How Does it Work

Lean Six Sigma, blending lean thinking/Six Sigma quality obsession, emerges revolutionizing industries.

Lean Six Sigma provides systematic guidance to resolve resource planning, coordination, and constraint-bound target fulfillment vitally. And improve operation workflow, elevate results, and buyer gratification.

Methodically addressing root defects from facts reaps optimization, enhancing fluidity and outputs throughout teams, associations, and industries seeking continuous upgrading amid volatile markets. Progress blossoms from shared insights.

Key Highlights

- Lean Six Sigma marries lean mindsets with Six Sigma quality monitoring – optimizing techniques, ditching waste, and upgrading yields.

- It strengthens project administration, upgrading wins, cutting expenditures, and bettering client satisfaction.

- Foundations, proficiency rankings, instruments, and methodologies link Lean Six Sigma directly into undertaking lifecycles—from conceptualizing through monitoring and conclusion.

- Insights surface applying these within the project environment, from challenges to triumph tales.

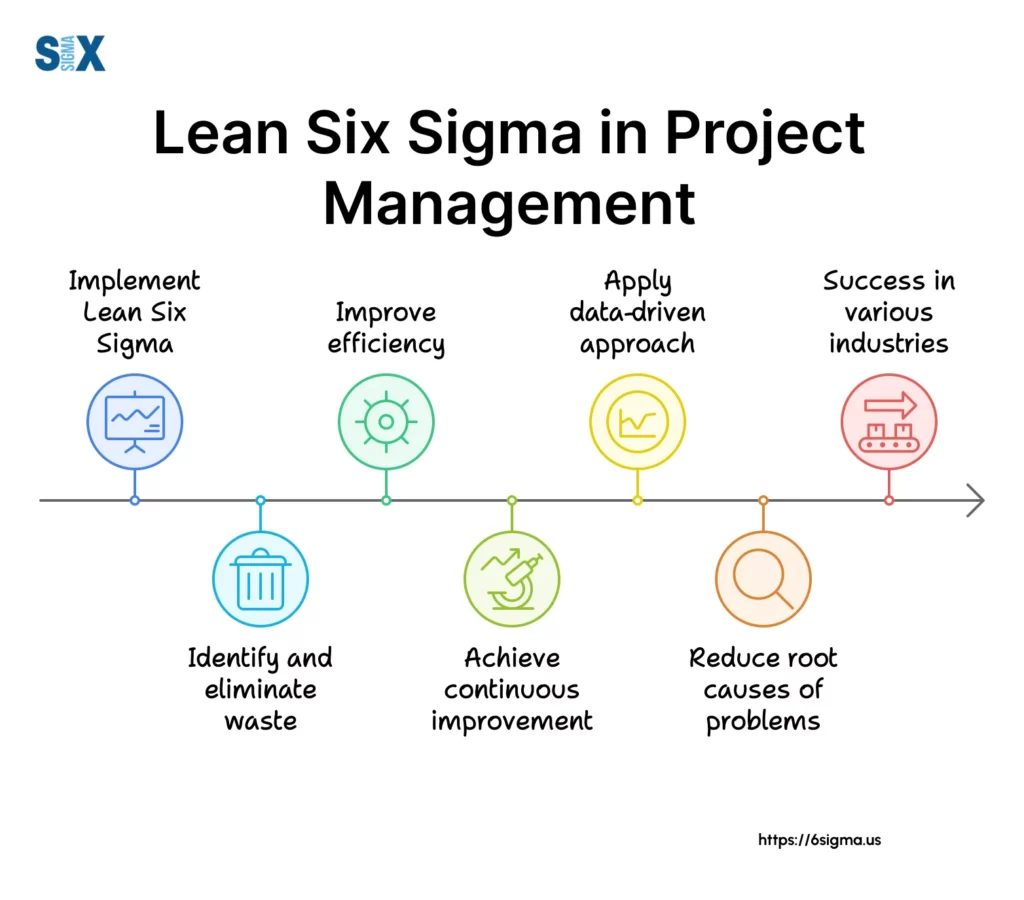

What is Lean Six Sigma in Project Management?

Applying lean philosophies and Six Sigma ways of thinking upgrades project coordination for stronger showings.

Lean Six Sigma in project management focuses on continuous refinement, client-centricity, and statistics-backed choices. Project administrators thereby enhance planning/execution, oversight, and results tallying to heightened win rates, savings, and buyer fulfillment.

Key emphases encompass wasted efforts truncation; higher quality assurances; synergistic team-spirit cultivation; and evidence-informed selections.

Popular tools incorporate Kanban panels; value stream schematics; analytical apparatuses; and procedures optimization. Proper appliance proves pivotal outcomes.

Benefactors emerge across domains—from programming through manufacturing and service industries as complexity proliferates and volatility persists unpredictably.

Adaptable techniques equip sustained advantage by optimizing information processing, collective acumen, and receptiveness aligning techniques resiliently through perpetual honing. Quality administration stays an uninterrupted journey.

Lean Six Sigma Principles and Methodology

At its core, Lean Six Sigma combines the principles and tools of two powerful process improvement methodologies – Lean and Six Sigma.

The Lean philosophy focuses on maximizing value while minimizing waste, while Six Sigma aims to reduce variation and defects through statistical analysis.

The key principles behind Lean Six Sigma include:

Customer Focus: Understanding and meeting customer needs and requirements is the driving force. All processes should aim to deliver maximum value to the customer.

Define, Measure, Analyze, Improve, Control (DMAIC): This structured Six Sigma methodology provides a data-driven approach to process improvement by defining issues, measuring performance, analyzing root causes, improving processes, and implementing controls.

Eliminate Waste: Lean principles emphasize identifying and eliminating non-value-added activities, overproduction, excess inventory, unnecessary motion, waiting times, defects, and other wastes.

Continuous Improvement: Lean Six Sigma encourages a mindset of continuous learning and incremental enhancements to optimize processes over time.

The combined Lean Six Sigma methodology typically follows the DMAIC cycle:

- Define: Clearly define the problem, goals, customers, and requirements.

- Measure: Gather data to establish current process performance baselines.

- Analyze: Identify root causes of defects and process variations through data analysis.

- Improve: Develop, test, and implement improvements to address root causes.

- Control: Implement controls to sustain improvements and establish continuous monitoring.

Lean Six Sigma Belts and Certification

Lean Six Sigma follows a structured belt-based certification program similar to martial arts. The different belt levels signify the training and expertise an individual has acquired in Lean Six Sigma principles and tools. The main belt levels are:

Yellow Belt: This is the entry-level certification that provides basic training in Lean Six Sigma fundamentals. Yellow Belts have a general understanding of the principles and methodologies.

Green Belt: Green Belts receive more comprehensive training and can apply Lean Six Sigma tools and techniques to smaller process improvement projects under the supervision of a Black Belt. They are equipped to be part of process improvement teams.

Black Belt: Black Belts are the disciplined experts who lead complex Lean Six Sigma projects. They have mastered data-driven improvement methodologies and advanced statistical tools. Black Belts train and mentor Green Belts.

Master Black Belt: At the highest level, Master Black Belts are distinguished experts with significant experience not just applying but also training others on Lean Six Sigma. They develop key metrics and strategic improvement plans for organizations.

Obtaining Lean Six Sigma certification, especially at the Green Belt and Black Belt levels, is highly valuable for project managers.

It demonstrates their capabilities in data analysis, process optimization, and driving efficient project execution aligned with Lean Six Sigma principles. Many organizations prioritize hiring and training certified Lean Six Sigma professionals for project roles.

The certification process involves intensive training, project work, and rigorous exams to validate one’s knowledge and skills at each belt level.

Applying Lean Six Sigma in Project Management

Lean Six Sigma principles and methodologies can be applied across all phases of the project management lifecycle to drive process improvement and optimize results. Here’s how it works:

Six Sigma Project Lifecycle

The Six Sigma methodology follows a structured data-driven approach known as DMAIC (Define, Measure, Analyze, Improve, Control). This aligns well with the typical project phases:

- Define: In this phase, the project team defines the problem, goal, requirements, and project scope. They create a project charter and identify key metrics and deliverables.

- Measure: The current process is measured and mapped to establish a baseline. Data is collected on defects, cycle times, costs, etc.

- Analyze: Using statistical analysis tools like process maps and cause-and-effect diagrams, the team analyzes the data to identify root causes of defects or inefficiencies.

- Improve: Solutions are developed and implemented, such as eliminating wasteful steps, reducing variation, or preventing errors. Lean principles help streamline the process.

- Control: The improved process is monitored and controlled through statistical process control methods to ensure continued improvements are sustained.

Six Sigma Project Planning

Careful upfront planning is critical, including creating a Six Sigma project charter that defines the problem statement, goals, team roles, project scope, and key deliverables. Risk analysis, change management, and training plans are also developed.

Six Sigma Project Execution

As the project is executed, Six Sigma tools like SIPOC, process mapping, 5 Whys, and hypothesis testing are leveraged. The team collects and analyzes data to identify and eliminate defects, waste, and sources of variation.

Six Sigma Project Monitoring and Control

Statistical process control methods like control charts are used to monitor the improved process. The team identifies trends and variations that require adjustments to keep the process on track.

Six Sigma Project Closure

At project closure, the team quantifies the improvements achieved through metrics like reduced defects, decreased costs, and increased productivity. Lessons learned are documented to enable continuous improvement.

Lean Six Sigma Tools for Project Management

Lean Six Sigma provides a powerful set of tools and techniques that can greatly benefit project management. Some of the key Lean Six Sigma tools used in project management include:

- Process Mapping: Tools like process flow charts, value stream maps, and SIPOC (Suppliers, Inputs, Process, Outputs, Customers) diagrams help visualize and analyze the processes involved in a project. This allows teams to identify waste, inefficiencies, and opportunities for improvement.

- Root Cause Analysis: Techniques like the 5 Whys, fishbone diagrams, and fault tree analysis enable teams to systematically identify and address the underlying root causes of project issues or defects.

- Data Analysis: Statistical tools such as histograms, Pareto charts, scatter plots, and control charts provide quantitative methods for analyzing project data, monitoring performance, and identifying areas for optimization.

- Lean Tools: Methods like 5S (Sort, Straighten, Shine, Standardize, Sustain), Kanban boards, and Kaizen events promote continuous improvement and help streamline project workflows by eliminating waste and non-value-added activities.

- Project Management Software: Dedicated Lean Six Sigma project management software solutions integrate Six Sigma principles and tools directly into the project management environment, enabling efficient data collection, analysis, and process improvement.

Challenges and Success Factors

Implementing Lean Six Sigma in project management is not without its challenges. One major hurdle is gaining buy-in and support from leadership and team members.

Lean Six Sigma requires a cultural shift and commitment to continuous improvement, which can be difficult to instill across an organization. Proper training is crucial to ensure everyone understands the principles, tools, and techniques involved.

Another challenge lies in selecting the right projects and areas to apply Lean Six Sigma methodology. It works best for repeatable, process-driven projects rather than unique, creative initiatives.

Identifying key processes that are ripe for optimization takes careful analysis. Inadequate process metrics and data can also hinder effective Lean Six Sigma deployment.

Despite the challenges, many organizations have realized immense success by combining Lean Six Sigma with project management. Critical success factors include:

- Top-Down Leadership Support: Visible endorsement and participation from executive leadership provides legitimacy and resources.

- Proper Training: Investing in comprehensive Six Sigma belts training and certifications equips teams with the skills to succeed.

- Data-Driven Decision Making: Lean Six Sigma’s reliance on data ensures fact-based process improvements rather than operating based on assumptions.

- Continuous Improvement Mindset: Embracing the philosophy of constantly identifying and eliminating waste and defects drives long-term optimization.

- Project Selection: Focusing Lean Six Sigma efforts on high-impact processes maximizes the return on investment.

Conclusion

Applying lean principles plus Six Sigma’s data-led precision streamlines undertaking regulation emphatically.

Together maximizing value while minimizing wastefulness and statistical framework optimize, such integration strengthens expediency, caliber and client satisfaction.

Implementation necessitates preparation, credentials proportionate exertions’ magnitudes, and wisely chosen tools aligned with endeavors’ whole lifecycles.

Culture too must shift progressively. Despite hurdles like training outlays and tectonic disposition, returns justify exertions.

Successful models demonstrate sweeping savings, expedited cycles, elevated quality and buyer delight cross-industries.

Lean Six Sigma synchronizes eminently with operational excellence goals and sustainable edge. It serves powerfully augmenting predictable, fruitful task transportation over both short and long horizons.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs