Lean Six Sigma Certification in 2024. The Ultimate Guide to Boost Your Career and Transform Organizations

Imagine being the driving force behind your organization’s efficiency and success, armed with a toolkit that can revolutionize processes and skyrocket productivity. That’s the power of Lean Six Sigma certification.

In this comprehensive guide, we’ll dive deep into the world of Lean Six Sigma certification. Whether you’re a seasoned professional looking to advance your career or a curious newcomer eager to understand this powerful methodology, you’re in the right place.

By the end of this article, you’ll have a clear understanding of:

- The core principles of Lean Six Sigma and its certification levels

- How Lean Six Sigma certification can boost your career and salary prospects

- Step-by-step guidance on obtaining your certification

- The costs associated with different certification levels

- Top-rated online certification programs and accreditation considerations

- Real-world applications of Lean Six Sigma across various industries

- Emerging trends and the future of Lean Six Sigma in the digital age

What is Lean Six Sigma Certification?

Lean Six Sigma certification is a professional credential that validates an individual’s expertise in the Lean Six Sigma methodology. But what is Lean Six Sigma certification, really? At its core, it’s a testament to your ability to improve processes, reduce waste, and drive efficiency in any organization.

The certification is built on two powerful methodologies: Lean, which focuses on eliminating waste and improving flow, and Six Sigma, which aims to reduce variation and enhance quality. Together, they form a robust framework for process improvement and problem-solving.

History and Evolution of Lean Six Sigma

As someone who’s been in this field for over two decades, I’ve witnessed the evolution of Lean Six Sigma firsthand. The roots of this methodology can be traced back to the 1980s when Motorola developed Six Sigma to improve their manufacturing processes. Lean, on the other hand, originated from Toyota’s production system in the mid-20th century.

It wasn’t until the late 1990s and early 2000s that these two methodologies were combined, giving birth to Lean Six Sigma. I remember the excitement in the industry when we realized the potential of this integrated approach.

Integration of Lean and Six Sigma Methodologies

The beauty of Lean Six Sigma lies in its synergy. While Lean focuses on speed and efficiency, Six Sigma emphasizes precision and consistency. In my experience working with companies like 3M and Dell, I’ve seen how this combination can lead to dramatic improvements in both quality and productivity.

For instance, in a project I led at a manufacturing plant, we used Lean principles to streamline the production line, reducing lead times by 40%. Simultaneously, we applied Six Sigma techniques to reduce defect rates, resulting in a 99.9% quality level. This is the power of Lean Six Sigma certification – it equips you with tools to tackle complex business challenges from multiple angles.

In essence, Lean Six Sigma certification is your passport to becoming a process improvement expert. It’s not just about learning theories; it’s about gaining practical skills that can transform businesses.

Ready to start your Lean Six Sigma journey? Our White Belt course provides a solid foundation in Lean Six Sigma principles.

Lean Six Sigma Certification Levels

I’ve had the privilege of guiding countless professionals through their Lean Six Sigma certification journey.

One of the most common questions I encounter is, “What are the different levels of Lean Six Sigma certification?” Let me break it down for you, drawing from my experience.

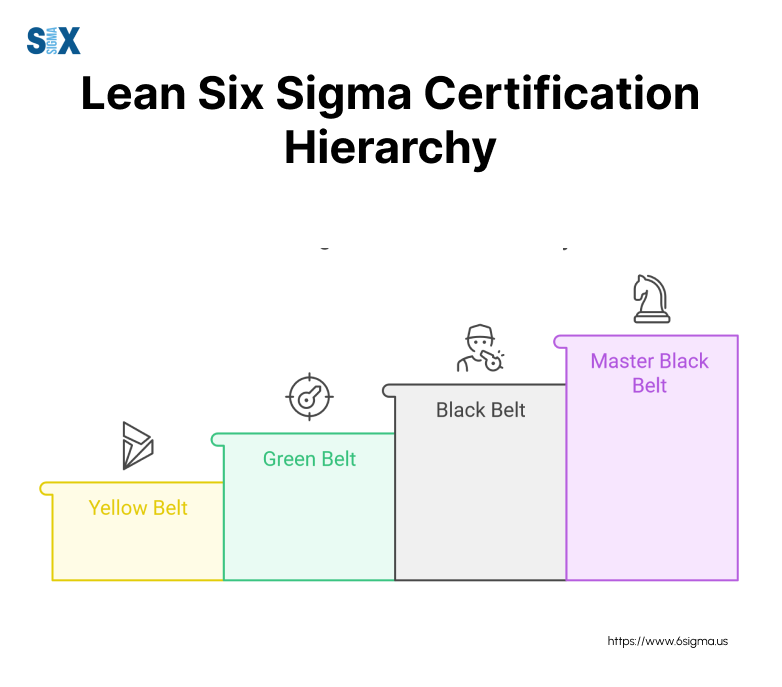

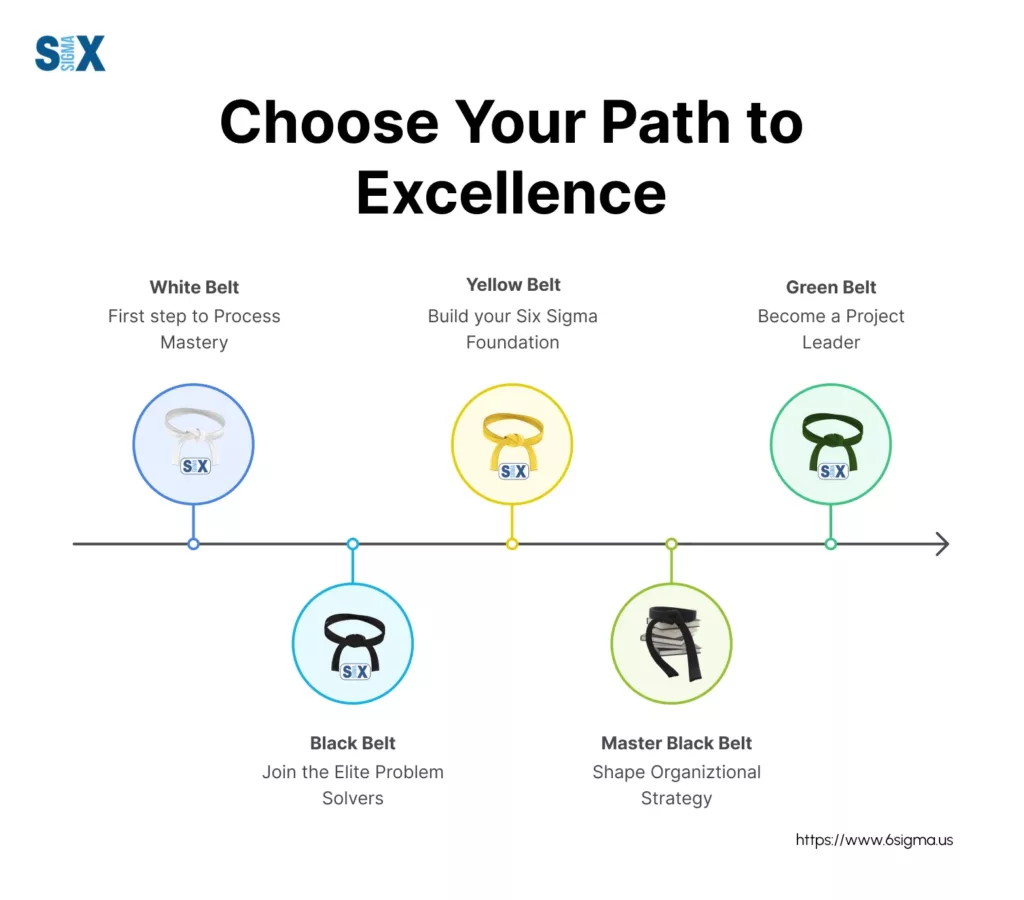

Lean Six Sigma certifications are structured in a belt system, similar to martial arts. Each belt represents a different level of expertise and responsibility in the Lean Six Sigma methodology. Let’s explore each level.

White Belt

The White Belt is the entry-level Lean Six Sigma certification. It’s designed for those who are new to the methodology and want to understand its basic concepts. In my experience, White Belts often serve as team members on improvement projects, supporting the efforts of more advanced practitioners.

Key Points

- Duration: Typically a one-day course

- Focus: Basic Lean Six Sigma concepts and terminology

- Typical Roles: Team members, general staff

Yellow Belt

Yellow Belt certification is the next step up. It provides a more in-depth understanding of Lean Six Sigma tools and techniques. When I conduct Yellow Belt training, I focus on equipping participants with the skills to participate actively in process improvement projects.

Key Points

- Duration: Usually 2-3 days of training

- Focus: Basic problem-solving tools, data collection, and process mapping

- Typical Roles: Team members, project support staff

Green Belt

Green Belt certification is where professionals start to take on leadership roles in Lean Six Sigma projects. I’ve seen many Green Belts drive significant improvements in their organizations. They have a comprehensive understanding of the DMAIC (Define, Measure, Analyze, Improve, Control) methodology and can lead medium-sized projects.

Key Points

- Duration: Typically 1-2 weeks of training plus project work

- Focus: Advanced statistical tools, project management, change management

- Typical Roles: Project leaders, process improvement specialists

Black Belt

Black Belt certification represents a high level of expertise in Lean Six Sigma. As a Black Belt myself before achieving Master Black Belt status, I can attest to the depth of knowledge and skills required at this level. Black Belts are full-time improvement specialists who lead complex projects and mentor Green Belts.

Key Points

- Duration: 4-5 weeks of training plus extensive project work

- Focus: Advanced statistical analysis, strategic project selection, coaching skills

- Typical Roles: Full-time improvement specialists, project leaders for high-impact initiatives

Master Black Belt

The Master Black Belt is the highest level of Lean Six Sigma certification. In my role as a Master Black Belt, I not only lead complex, high-stakes projects but also develop deployment strategies, train other belts, and act as a technical expert and coach for the entire organization.

Key Points

- Duration: Years of experience as a Black Belt plus additional training

- Focus: Organizational strategy, advanced statistical methods, training and mentoring

- Typical Roles: Lean Six Sigma program leaders, consultants, trainers

In my experience leading Lean Six Sigma deployments across various industries, I’ve found that organizations benefit most when they have a mix of practitioners at different belt levels. This creates a robust ecosystem of continuous improvement, with each level supporting and mentoring the others.

Ready to take your Lean Six Sigma skills to the next level? Explore our comprehensive Green Belt certification program.

Benefits of Lean Six Sigma Certification

It’s not just a line on your resume; it’s a catalyst for career growth, increased earning potential, and organizational excellence. Let me share with you the key benefits I’ve observed and experienced throughout my career.

Career Advancement Opportunities

Lean Six Sigma certification opens doors to a wide range of career opportunities. I’ve seen professionals from various backgrounds – engineers, project managers, even HR specialists – leverage their certification to take on leadership roles in process improvement initiatives.

For instance, one of my former students, a mid-level manager at a manufacturing company, used her Green Belt certification to spearhead a major efficiency project.

The success of that project fast-tracked her promotion to Director of Operations within a year. This is just one of many success stories I’ve encountered.

Salary Potential

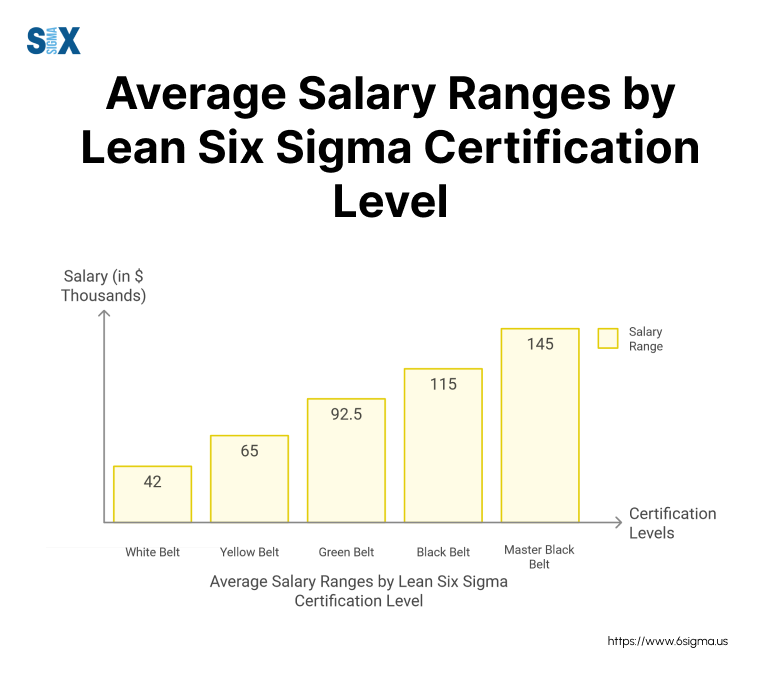

Let’s talk numbers. In my experience, Lean Six Sigma certification can significantly boost your earning potential. According to recent data I’ve compiled from industry surveys and my network:

- Yellow Belts typically see a 5-10% increase in salary

- Green Belts often command 20-25% higher salaries

- Black Belts can earn 30-40% more than their non-certified peers

- Master Black Belts are often in the top 10% of earners in their organizations

These figures aren’t just statistics; they represent real career transformations I’ve witnessed. One Black Belt I trained went from earning $75,000 to over $100,000 within 18 months of certification, thanks to the value he brought to his organization.

Organizational Impact

The benefits of Lean Six Sigma certification extend beyond individual careers. Certified professionals drive significant organizational change. In my work with companies like 3M and GE, I’ve seen Lean Six Sigma projects lead to:

- 20-30% reduction in operating costs

- 50% improvement in process cycle times

- Millions of dollars in annual savings

One project I led at a Fortune 500 company resulted in $5 million in savings in just six months. This level of impact not only boosts the bottom line but also enhances job security for Lean Six Sigma practitioners.

A hiring manager at a leading tech firm, told me recently, “Candidates with Lean Six Sigma certification stand out. They bring a structured approach to problem-solving that’s invaluable in today’s fast-paced business environment”.

In my experience, the benefits of Lean Six Sigma certification are clear and compelling. It’s not just about personal gain; it’s about equipping yourself with the tools to make a real difference in your organization.

Whether you’re looking to advance your career, increase your earning potential, or drive meaningful change in your company, Lean Six Sigma certification is a powerful way to achieve your goals.

How to Get Lean Six Sigma Certified

After two decades of guiding professionals through their Lean Six Sigma certification journey, I’ve developed a keen understanding of what it takes to succeed. Let me walk you through the process of how to get Lean Six Sigma certified, drawing from my experience as both a Master Black Belt and a trainer.

Choosing the Right Certification Level

The first step in your Lean Six Sigma certification journey is selecting the appropriate belt level. This decision should align with your career goals and current experience. Here’s my advice:

- White or Yellow Belt: Ideal for those new to Lean Six Sigma or looking for a basic understanding.

- Green Belt: Perfect for professionals who want to lead projects part-time.

- Black Belt: Suited for those aiming to become full-time Lean Six Sigma practitioners.

- Master Black Belt: For experienced Black Belts ready to train others and lead organizational change.

Remember, you can always progress through the levels as your expertise grows!

Preparation and Training Options

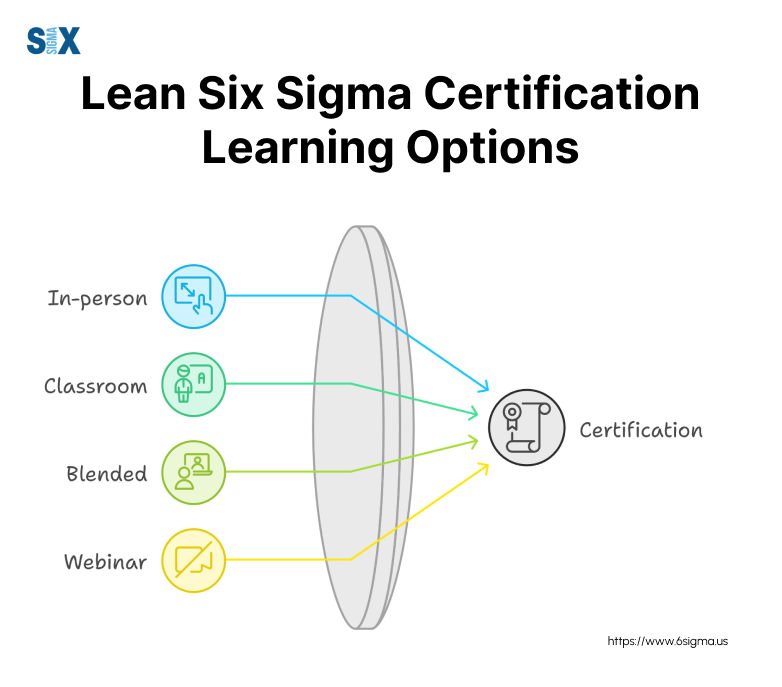

When it comes to Lean Six Sigma certification training, you have several options:

- In-person training: Offers hands-on experience and direct interaction with instructors.

- Online self-paced courses: Flexible and often more affordable.

- Live online training: Combines the benefits of in-person instruction with the convenience of online learning.

In my experience leading workshops globally, I’ve found that a blended approach often works best. For example, one of my students combined online modules with in-person project work, allowing her to apply her learning immediately in her organization.

Examination Process

The certification exam is the final hurdle in your Lean Six Sigma journey. Here’s what you can expect:

- Format: Usually multiple-choice, with some scenario-based questions.

- Duration: Typically 3-4 hours, depending on the belt level.

- Pass mark: Often around 70-80%, but this can vary by certification body.

My top tip for exam success? Practice, practice, practice. Use sample exams and case studies to familiarize yourself with the question style and time constraints.

Remember, getting Lean Six Sigma certified is a journey, not just a destination. Each level builds on the previous one, providing you with a comprehensive toolkit for driving organizational excellence. Whether you’re just starting with a White Belt or aiming for that coveted Master Black Belt, the key is to apply what you learn in real-world situations.

Online Lean Six Sigma Certification Options

In my two decades as a Lean Six Sigma Master Black Belt and trainer, I’ve witnessed a significant shift towards online certification options.

This trend has accelerated in recent years, making Lean Six Sigma certification more accessible than ever. Let’s explore the world of online Lean Six Sigma certification, drawing from my experience in developing and delivering both in-person and online training programs.

Benefits of Online Certification

Online Lean Six Sigma certification offers several advantages:

- Flexibility: Learn at your own pace and schedule, which is ideal for working professionals.

- Cost-effectiveness: Often more affordable than traditional classroom training.

- Global access: Participate from anywhere in the world, as I’ve seen with my international students.

- Immediate application: Apply learnings to your work environment in real-time.

- Diverse learning resources: Access to a wide range of materials, including videos, interactive simulations, and downloadable tools.

However, it’s important to note that online learning requires self-discipline and time management skills. In my experience, successful online learners are those who create a structured study schedule and stick to it.

Top Online Certification Providers

Based on my industry knowledge and feedback from thousands of students, here are some of the best Lean Six Sigma certification online providers:

- SixSigma.us: Our program offers comprehensive training with live instructor support.

- ASQ (American Society for Quality): Known for rigorous standards and global recognition.

- Villanova University: Offers academic credibility combined with practical application.

- IASSC (International Association for Six Sigma Certification): Focuses exclusively on Lean Six Sigma.

- Purdue University: Provides a strong theoretical foundation with industry applications.

When choosing an online program, consider factors like course content, instructor expertise, hands-on project requirements, and post-certification support. For instance, at SixSigma.us, we offer ongoing mentoring to our certified professionals, which I’ve found crucial for the application of Lean Six Sigma principles.

Ensuring Accreditation and Recognition

Accreditation is crucial when selecting an online Lean Six Sigma certification program. Here are my tips for verifying accreditation and industry recognition:

- Check for affiliation with recognized bodies: Look for programs associated with ASQ, IASSC, or reputable universities.

- Research industry acceptance: Investigate if the certification is recognized in your industry or target companies.

- Review the curriculum: Ensure it covers all essential Lean Six Sigma tools and methodologies.

- Examine the experience requirements: Legitimate programs often require project work or practical application.

- Look for transparency in the certification process: Clear information about exam formats, pass rates, and recertification requirements is a good sign.

Remember, the best Lean Six Sigma certification online is one that not only provides thorough knowledge but also equips you with practical skills.

In my experience leading projects at companies like 3M and GE, I’ve found that employers value certifications that demonstrate real-world application over those that are purely theoretical.

Choosing the right online Lean Six Sigma certification program is a crucial step in your professional development journey. Whether you’re aiming for a Yellow Belt to understand the basics or pursuing a Black Belt to lead complex projects, online certification can provide you with the knowledge and skills you need to excel in process improvement.

Learn more about our comprehensive and flexible training options. Get Six Sigma Training and Certification via classroom, blended, onsite, online, and live webinar programs.

Lean Six Sigma Certification Costs

It’s a crucial consideration for individuals and organizations alike. Let me break down the Lean Six Sigma certification cost structure based on my experience and industry knowledge.

Factors Affecting Certification Costs

Several factors influence the cost of Lean Six Sigma certification:

- Certification level: Higher belt levels generally cost more due to increased training duration and complexity.

- Training provider: Costs can vary significantly between universities, professional associations, and private training companies.

- Training format: Online courses are typically less expensive than in-person training.

- Geographic location: Prices can differ based on your location, especially for in-person training.

- Included materials: Some programs include textbooks, software licenses, or exam fees in their pricing.

In my years of developing training programs at SixSigma.us, I’ve always aimed to balance comprehensive content with cost-effectiveness. It’s crucial to consider the value you’re getting, not just the price tag.

ROI of Lean Six Sigma Certification

While the upfront Lean Six Sigma certification cost might seem significant, the return on investment (ROI) can be substantial. In my experience:

- Green Belts often lead projects that save their organizations $50,000 to $100,000 annually.

- Black Belts frequently drive savings of $200,000 to $500,000 per year.

- Master Black Belts can influence organizational savings in the millions.

For example, a Black Belt I trained at a manufacturing company led a project that reduced defects by 70%, resulting in annual savings of $350,000. This far outweighed the initial certification investment.

Moreover, certified professionals often see salary increases. Based on the data I’ve collected:

- Green Belts typically see a 20-25% salary increase post-certification.

- Black Belts often command 30-40% higher salaries than non-certified peers.

When considering the Lean Six Sigma certification cost, it’s essential to view it as an investment in your career and your organization’s success. The skills you gain can lead to significant process improvements, cost savings, and career advancements that far outweigh the initial expenditure.

Transform your career and organization with Lean Six Sigma. Explore our full range of certification programs, from White Belt to Master Black Belt.

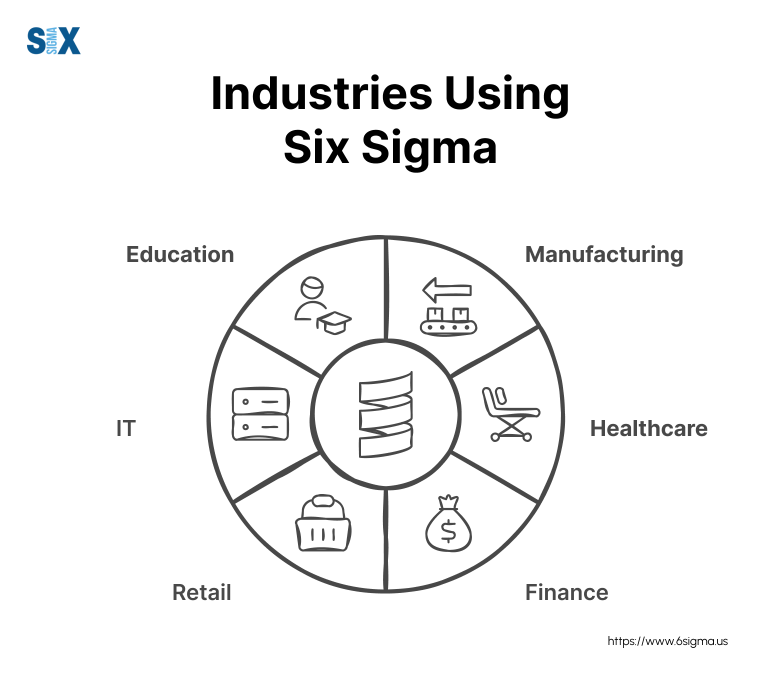

Industry-Specific Applications of Lean Six Sigma

What continually amazes me is the versatility and power of Lean Six Sigma in solving complex problems, regardless of the sector.

Let’s explore how Lean Six Sigma training and certification can drive improvements in various industries, drawing from my personal experiences and the successes I’ve witnessed.

Manufacturing

Manufacturing was where I cut my teeth in Lean Six Sigma, particularly during my tenure at 3M. In this sector, Lean Six Sigma is all about optimizing production lines, reducing defects, and minimizing waste.

Case Study: At a large automotive parts manufacturer, I led a Black Belt project that reduced defect rates by 75% and increased production speed by 30%. The key was using Statistical Process Control (SPC) to identify and eliminate sources of variation in the production process.

Unique Challenges

- High-volume production with tight tolerances

- Complex supply chains

- Balancing quality with speed

Healthcare

In healthcare, Lean Six Sigma can literally save lives. I’ve worked with several hospitals and pharmaceutical companies to improve patient care and drug development processes.

Case Study: At a major hospital, we implemented a Lean Six Sigma project to reduce emergency room wait times. By optimizing patient flow and resource allocation, we cut average wait times from 55 minutes to 25 minutes, significantly improving patient satisfaction and outcomes.

Unique Challenges

- Regulatory compliance

- Patient safety concerns

- Resistance to change in traditional medical practices

Finance

The finance sector might seem far removed from manufacturing, but Lean Six Sigma principles apply just as effectively. I’ve helped banks and financial institutions streamline operations and improve customer service.

Case Study: For a large retail bank, we used Lean Six Sigma methodologies to overhaul their loan approval process. The result? A 40% reduction in processing time and a 25% increase in customer satisfaction scores.

Unique Challenges

- Data security and privacy concerns

- Complex regulatory environment

- Need for real-time decision-making

IT Services

In the fast-paced world of technology, Lean Six Sigma helps companies stay agile and efficient. My work with tech giants like Dell and HP has shown me the immense potential in this sector.

Case Study: At a major software company, we applied Lean Six Sigma principles to their software development process. By identifying and eliminating bottlenecks, we reduced time-to-market for new features by 35% without compromising quality.

Unique Challenges

- Rapidly changing technology landscape

- Balancing innovation with process standardization

- Managing distributed, global teams

The versatility of Lean Six Sigma across these diverse sectors underscores why Lean Six Sigma training and certification are so valuable. Whether you’re in manufacturing, healthcare, finance, technology, or any other industry, the principles you learn can be adapted to drive significant improvements.

In my experience, professionals who pursue Lean Six Sigma certification often find that their skills are highly transferable across industries. This versatility not only enhances career prospects but also allows organizations to benefit from cross-industry insights and best practices.

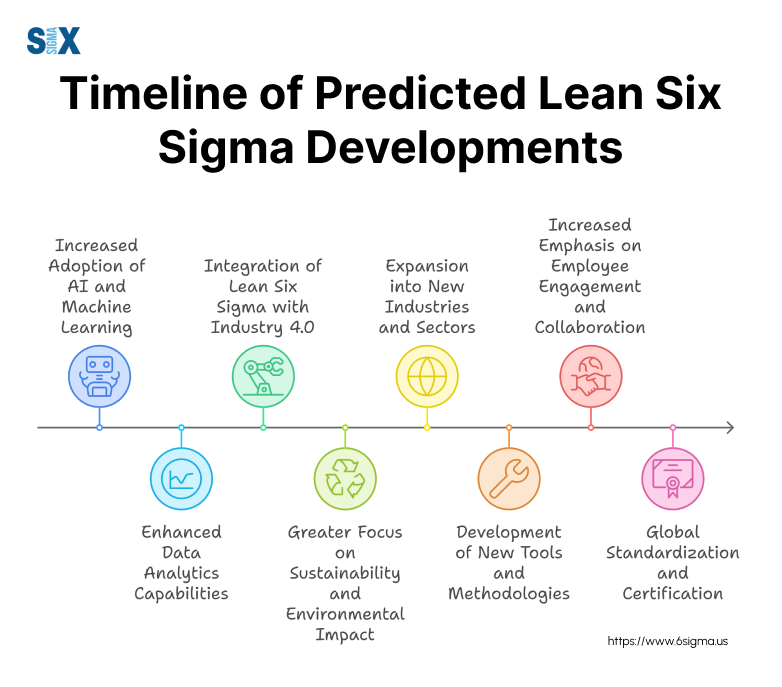

Future Trends in Lean Six Sigma Certification

Looking ahead, I see exciting developments that will shape the future of Lean Six Sigma certification and its application in the business world. Let me share my insights on what’s coming next.

Integration with Emerging Technologies

The fusion of Lean Six Sigma with cutting-edge technologies is revolutionizing how we approach process improvement. In my recent projects, I’ve seen firsthand how AI and IoT are enhancing Lean Six Sigma methodologies:

- AI-powered data analysis: Machine learning algorithms are now capable of identifying patterns and anomalies in processes faster than ever before. This allows Lean Six Sigma practitioners to focus more on solution design and implementation.

- IoT for real-time monitoring: Internet of Things devices are providing continuous, real-time data on processes. This level of insight was unimaginable when I started my career at 3M, but now it’s becoming standard in many industries.

- Augmented Reality (AR) in training: AR is making Lean Six Sigma certification training more interactive and engaging. I’m currently developing AR modules for our online certification courses at SixSigma.us to enhance the learning experience.

Global Perspectives and Cross-Cultural Applications

As someone who’s led international projects in over 100 countries, I’ve seen how Lean Six Sigma is adapting to diverse cultural contexts:

- Customized certification programs: We’re seeing a rise in Lean Six Sigma certification programs tailored to specific regional needs and business cultures.

- Virtual global teams: With remote work becoming more common, Lean Six Sigma practitioners need to be adept at leading improvement projects across geographically dispersed teams.

- Cross-cultural problem-solving: Future Lean Six Sigma certifications will likely include more emphasis on navigating cultural differences in process improvement approaches.

Continuous Learning and Recertification

The rapidly evolving business landscape means that Lean Six Sigma certification is no longer a one-and-done achievement. Continuous learning is key:

- Micro-certifications: We’re introducing shorter, more focused certifications at SixSigma.us to address specific skills or industry applications.

- Recertification requirements: Many organizations are now requiring periodic recertification to ensure practitioners stay current with the latest methodologies and tools.

- Integration with other disciplines: Future Lean Six Sigma certifications may incorporate elements of change management, design thinking, and agile methodologies to create more well-rounded practitioners.

Lean Six Sigma certification will continue to evolve, embracing new technologies and adapting to changing business needs. For professionals considering Lean Six Sigma certification, this means exciting opportunities to stay at the cutting edge of process improvement methodologies.

Future Trends in Lean Six Sigma

- Integration of AI and IoT in process analysis

- Customized, culturally-sensitive certification programs

- Emphasis on leading virtual global teams

- Introduction of micro-certifications for specific skills

- Increased focus on continuous learning and recertification

- Incorporation of complementary methodologies like agile and design thinking

In my view, these trends underscore the enduring value of Lean Six Sigma certification. As businesses face increasingly complex challenges, the ability to drive efficient, data-driven improvements will only become more crucial.

Conclusion

Lean Six Sigma certification is more than just a credential; it’s a pathway to becoming a catalyst for meaningful change in your organization.

From reducing waste and improving efficiency to driving innovation and boosting bottom lines, the skills you gain through Lean Six Sigma certification are invaluable in today’s competitive business landscape.

Whether you’re a recent graduate looking to kickstart your career, a seasoned professional aiming to take your skills to the next level, or an organization seeking to embed a culture of continuous improvement, Lean Six Sigma certification offers a structured approach to achieving your goals.

Take the first step today. Explore the certification levels we’ve discussed, from White Belt to Master Black Belt, and determine which aligns best with your goals. Consider the online Lean Six Sigma certification options we’ve outlined, keeping in mind the importance of accredited programs.

At SixSigma.us, we’re committed to guiding professionals like you through every step of your Lean Six Sigma journey. Whether you’re looking for Lean Six Sigma training and certification or seeking to implement these methodologies in your organization, we’re here to help.

Don’t let this opportunity for growth and advancement pass you by. Invest in your future, enhance your problem-solving skills, and position yourself as a valuable asset in any industry. The world of Lean Six Sigma is evolving, and with it, the potential for your career to reach new heights.

Take action now. Your journey towards becoming a Lean Six Sigma certified professional starts here!

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs