Lean Problem Solving Techniques. The Definitive Guide to Operational Excellence

In today’s fast-paced business world, efficiency isn’t just an advantage — it’s a necessity. This powerful methodology isn’t just a tool; it’s the secret weapon that sets successful companies apart from their competitors.

Whether you’re a seasoned business professional, a project manager looking to streamline operations, or a process improvement enthusiast eager to make a difference, this comprehensive guide to lean problem-solving will equip you with the knowledge and skills you need to drive meaningful change in your organization.

But we won’t stop at theory. Drawing from my extensive experience, I’ll share real-world case studies and practical examples that illustrate the transformative power of lean problem-solving. We’ll also look ahead to the future, exploring how emerging technologies and trends are shaping the evolution of this critical business skill.

What is Lean Problem Solving?

I’ve seen firsthand how lean problem-solving can revolutionize businesses across various industries. But what exactly is lean problem solving, and why is it so crucial in today’s fast-paced business environment?

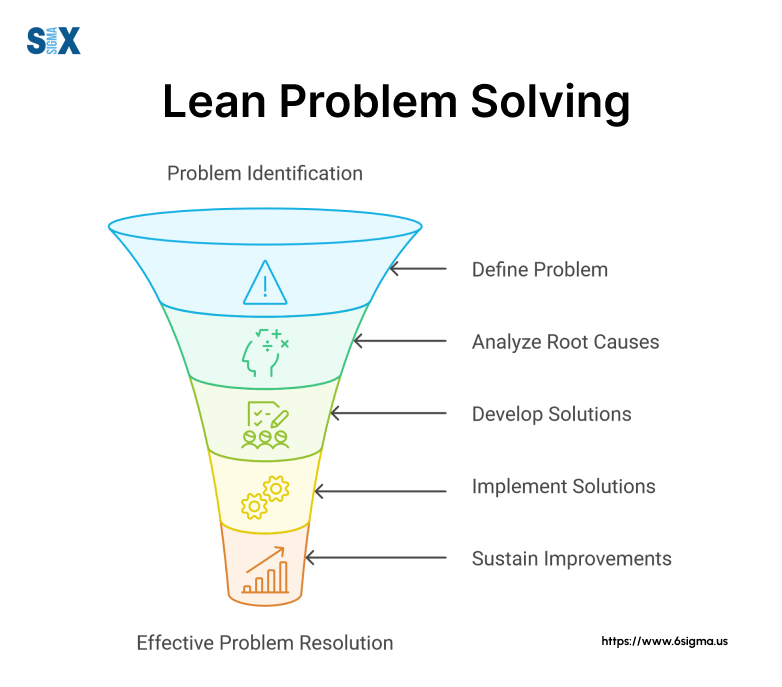

Lean problem-solving is a systematic, data-driven approach to identifying, analyzing, and resolving issues within an organization. It’s not just about fixing problems; it’s about creating a culture of continuous improvement. At its core, lean problem-solving is about maximizing value while minimizing waste.

The roots of lean problem-solving trace back to the Toyota Production System (TPS) developed in the mid-20th century.

The key principles of lean problem-solving include:

- Focus on customer value

- Identify and eliminate waste

- Continuous improvement (Kaizen)

- Respect for people

- Make decisions based on long-term philosophy

These principles form the foundation of what we call “problem-solving lean” – a methodology that’s transforming how businesses approach challenges.

As a chemical engineer who’s worked extensively with manufacturing giants like 3M and Dell, I’ve seen how these principles, originally designed for manufacturing efficiency, have evolved into a versatile problem-solving methodology applicable across various sectors.

Benefits of Lean Problem Solving

The benefits of adopting lean problem-solving techniques are substantial:

- Increased efficiency: By eliminating waste, organizations can streamline processes and boost productivity.

- Improved quality: Lean methodologies focus on reducing defects and variability, leading to higher quality outputs.

- Enhanced customer satisfaction: By focusing on value from the customer’s perspective, businesses can better meet and exceed customer expectations.

- Cost reduction: Eliminating waste and improving efficiency naturally leads to cost savings.

- Empowered workforce: Lean problem-solving encourages employee involvement, leading to higher engagement and job satisfaction.

In my work with companies like GE and HP, I’ve seen these benefits translate into tangible results. For instance, one manufacturing client reduced their product development cycle time by 40% after implementing lean problem-solving methods.

Lean problem-solving differs from traditional problem-solving approaches in its focus on continuous improvement and waste elimination. While traditional methods might focus on quick fixes, lean problem-solving aims to address root causes and create sustainable solutions.

Key Lean Problem-Solving Techniques

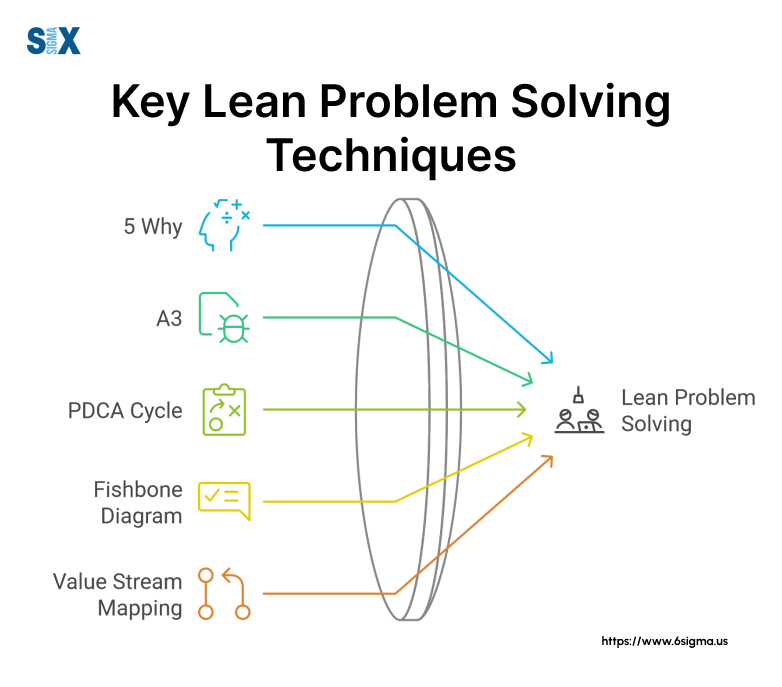

In this section, I’ll share some of the most effective lean problem-solving methods I’ve encountered and applied throughout my career. These techniques form the backbone of practical problem-solving in lean management and are crucial for anyone looking to master lean Six Sigma problem-solving.

The 5 Whys

The 5 Whys is a fundamental lean problem-solving technique that I’ve found incredibly effective in uncovering root causes. It’s a simple yet powerful tool that involves asking “Why?” repeatedly to dig deeper into a problem.

How it works

- State the problem

- Ask why the problem occurs and write down the answer

- If the answer doesn’t identify the root cause, ask “Why?” again

- Repeat the process five times or until you’ve identified the root cause

Example from my experience

While working with a major electronics manufacturer, we faced recurring quality issues with a new product line. Here’s how we applied the 5 Whys:

- Why are we seeing defects in the final product?

Because the circuit boards are faulty. - Why are the circuit boards faulty?

Because they’re not soldered correctly. - Why aren’t they soldered correctly?

Because the soldering temperature is inconsistent. - Why is the soldering temperature inconsistent?

Because the soldering equipment is outdated and poorly maintained. - Why is the equipment outdated and poorly maintained?

Because there’s no regular maintenance schedule or budget for equipment upgrades.

This process led us to implement a robust maintenance schedule and allocate a budget for equipment upgrades, solving the quality issues at their root.

A3 Problem Solving

A3 problem-solving is a structured problem-solving and continuous improvement approach that I’ve found particularly useful in lean management problem solving. It’s named after the A3-sized paper used to document the process.

Key components of A3

- Problem Statement

- Current Condition

- Goal/Target Condition

- Root Cause Analysis

- Countermeasures

- Implementation Plan

- Follow-up Actions

I’ve successfully used A3 in various scenarios, from improving manufacturing processes to optimizing supply chain operations at a computer hardware and software manufacturer. The visual nature of A3 makes it an excellent tool for communicating complex problems and solutions across teams.

PDCA Cycle

The Plan-Do-Check-Act (PDCA) cycle is a four-step lean problem solving process that I’ve found invaluable in lean manufacturing problem solving. It’s an iterative approach that promotes continuous improvement.

Steps in PDCA

- Plan: Identify and analyze the problem

- Do: Develop and implement a solution

- Check: Evaluate the results

- Act: Standardize the solution if successful or begin the cycle again

In my work with GE, we used PDCA to improve a production line’s efficiency. We planned process changes, implemented them on a small scale, checked the results, and then acted to roll out successful changes across the entire line. This iterative approach led to a 30% increase in productivity.

Fishbone Diagram

Also known as the Ishikawa diagram, the fishbone diagram is a visual lean problem-solving technique that I’ve found it particularly useful in brainstorming sessions. It helps teams identify potential causes of a problem across different categories.

How to create a fishbone diagram

- Define the problem (the “head” of the fish)

- Identify major categories of potential causes (the “bones”)

- Brainstorm potential causes within each category

- Analyze the results to identify the most likely root causes

I’ve used this technique extensively in Six Sigma problem-solving, particularly when dealing with complex quality issues that have multiple potential causes.

Value Stream Mapping

Value Stream Mapping (VSM) is a lean tool that helps visualize the steps in a process and identify areas of waste. It’s particularly useful in lean manufacturing problem-solving and process improvement.

Key steps in VSM

- Select a product family

- Create a current state map

- Identify areas of waste

- Create a future state map

- Develop an implementation plan

During a project, we used VSM to streamline a complex production process, reducing lead time by 40% and improving quality by eliminating non-value-adding steps.

These lean problem-solving techniques form the core of effective lean Six Sigma problem-solving. By mastering these methods, you’ll be well-equipped to tackle complex business challenges and drive continuous improvement in your organization.

Ready to master these powerful Lean problem-solving techniques? Take your skills to the next level with our Lean Fundamentals course that covers these techniques and more.

Implementing Lean Problem Solving in Your Organization

I’ve learned that successful implementation is as much about culture change as it is about methodology. In this section, I’ll share my insights on how to effectively integrate lean problem-solving into your organization’s DNA.

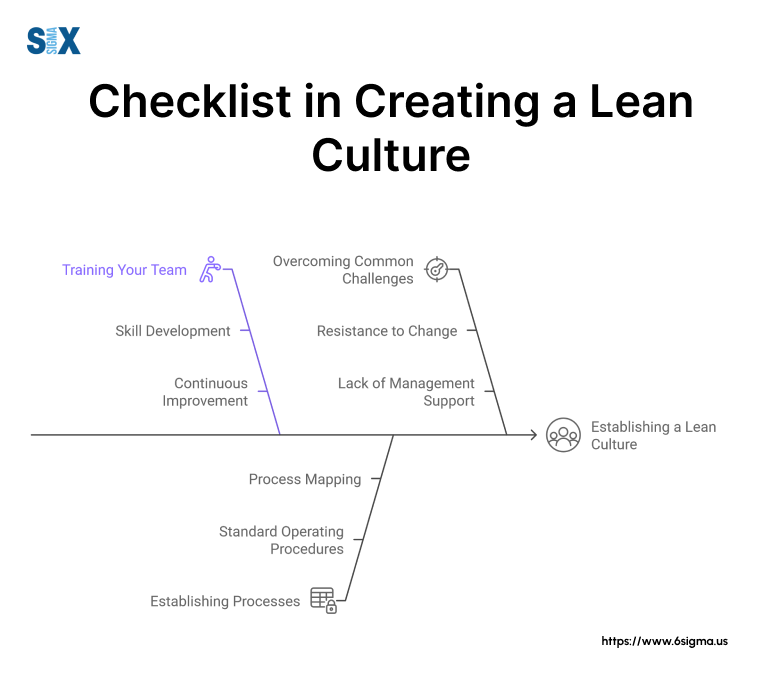

Creating a Lean Culture

The foundation of successful lean problem-solving implementation is a culture that embraces continuous improvement. Here’s how to foster this culture:

- Lead by example: As a leader, your commitment to lean principles sets the tone for the entire organization. I’ve seen firsthand how executive buy-in at companies like Intel and Motorola drove successful lean transformations.

- Encourage open communication: Create an environment where employees feel safe to identify problems and suggest improvements. At 3M, we implemented a “no-blame” policy that significantly increased problem reporting and resolution.

- Celebrate small wins: Recognize and reward teams for their problem-solving efforts, no matter how small. This reinforces the value of continuous improvement.

- Make it visible: Use visual management tools like lean problem-solving boards to make progress and challenges visible to everyone.

Training Your Team

Effective lean problem solving training is crucial for successful implementation. Based on my experience developing Six Sigma deployment strategies, here’s what I recommend:

- Start with the basics: Ensure everyone understands the fundamental concepts of lean and Six Sigma problem-solving.

- Provide hands-on experience: Use real-world problems from your organization in training sessions. This approach worked wonders when I led workshops for engineers and process developers at Xerox.

- Develop internal champions: Identify and train individuals who can become internal experts and advocates for lean problem-solving.

- Offer ongoing education: Lean problem-solving is a journey, not a destination. Continual learning opportunities keep skills sharp and methodologies up-to-date.

Establishing Problem-Solving Processes

To make lean problem-solving a part of daily operations, you need clear, standardized processes:

- Define trigger points: Establish criteria for when to initiate formal problem-solving processes.

- Create standard templates: Develop A3 or other problem-solving templates that guide teams through the process consistently.

- Set up regular review meetings: Schedule frequent check-ins to review progress and provide support.

- Integrate with existing systems: Ensure lean problem-solving methods complement your existing project management tools, whether it’s Jira for lean problem-solving or other platforms.

Overcoming Common Challenges

In my international consulting work, I’ve encountered several recurring challenges in lean problem-solving implementation. Here’s how to address them:

- Resistance to change: Communicate the benefits clearly and involve employees in the process. When I worked with HP, we formed cross-functional teams to drive change from within.

- Lack of time: Start small and demonstrate how lean problem-solving saves time in the long run. At Seagate, we began with pilot projects that showed quick wins.

- Data overload: Focus on collecting only the most relevant data. I’ve helped many organizations streamline their data collection processes to avoid analysis paralysis.

- Sustaining momentum: Regular check-ins, continuous training, and visible progress tracking help maintain enthusiasm and commitment.

- Engagement: Downloadable Lean Problem-Solving Implementation Checklist

To help you get started, I’ve created a comprehensive checklist based on my years of experience implementing lean problem-solving across various industries.

Remember, implementing lean problem-solving is not a one-time event, but a continuous process of improvement. It requires patience, persistence, and a willingness to learn and adapt. But the rewards – increased efficiency, improved quality, and a more engaged workforce – are well worth the effort.

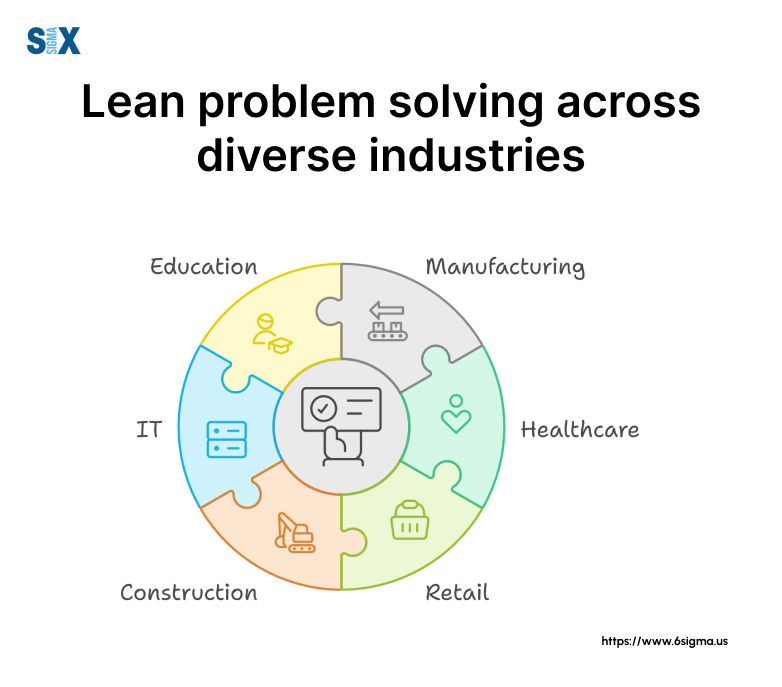

Lean Problem Solving Across Industries

In this section, I’ll share my insights on how lean problem-solving adapts and thrives in different industrial contexts.

Manufacturing

Manufacturing was the birthplace of lean methodologies, and it remains a powerhouse for lean problem-solving applications. During a project for an industrial manufacturer, I spearheaded numerous lean manufacturing problem-solving initiatives that yielded significant results.

Case Study: At a plant producing adhesive products, we implemented a lean problem-solving process focused on reducing waste in the coating line. Using the 5 Whys technique, we uncovered that inconsistent raw material quality was a root cause of excessive scrap. By working with suppliers and implementing stricter quality controls, we reduced scrap by 35% and increased productivity by 20%.

Key Challenges in Manufacturing

- Complex supply chains

- High-volume production with low margins

- Stringent quality requirements

Healthcare

The healthcare industry has embraced lean problem-solving methods to improve patient care, reduce costs, and enhance operational efficiency. My work with several hospitals has shown the transformative power of lean in this critical sector.

Case Study: At a large urban hospital, we used Lean Six Sigma problem-solving to address long emergency room wait times. Through value stream mapping, we identified several non-value-adding steps in the patient intake process. By streamlining these processes and implementing a new triage system, we reduced average wait times by 40% and improved patient satisfaction scores significantly.

Key Challenges in Healthcare

- Regulatory compliance

- Patient safety concerns

- Resistance to change in established medical practices

Software Development

The fast-paced world of software development has adapted lean principles to create methodologies like Agile and Scrum. During my collaborations with tech companies like Intel and HP, I’ve seen how lean problem solving can accelerate development cycles and improve product quality.

Case Study: At a leading software company, we applied lean problem-solving techniques to their development process. By implementing daily stand-up meetings (a core component of Scrum) and using Kanban boards (a lean tool for visualizing workflow), the team reduced bug rates by 30% and shortened release cycles by 25%.

Key Challenges in Software Development

- Rapidly changing technology landscapes

- Balancing innovation with stability

- Managing distributed teams

Service Industries

Service industries, from finance to hospitality, have found innovative ways to apply lean problem solving. My experience with service-oriented companies has shown that lean principles can significantly enhance customer satisfaction and operational efficiency.

Case Study: For a major bank, we used lean management problem-solving to improve their customer service call center operations. By applying the PDCA (Plan-Do-Check-Act) cycle, we identified and eliminated several redundant processes. This led to a 20% reduction in average call handling time and a 15% increase in customer satisfaction scores.

Key Challenges in Service Industries

- Intangible nature of services

- High customer interaction

- Variability in demand

Now, let’s put your lean problem-solving skills to the test. Consider the following scenario:

A mid-sized e-commerce company is struggling with a high rate of returns for their products. Using the lean problem-solving methods we’ve discussed, how would you approach this issue?

- What lean problem-solving technique would you start with and why?

- What data would you collect to understand the problem better?

- How would you involve different departments in the problem-solving process?

- What potential solutions might you consider based on lean principles?

Take a moment to think through these questions. This exercise will help you apply lean problem-solving techniques to a real-world scenario, much like the challenges I’ve faced in my consulting work across various industries.

As we’ve seen, lean problem-solving is a versatile methodology that can be adapted to virtually any industry. Whether you’re in manufacturing, healthcare, tech, or services, the principles of lean can help you identify root causes, eliminate waste, and continuously improve your processes.

Ready to become an expert in advanced lean problem-solving methodologies? Get started with our Lean Master course to drive lean projects and boost organizational growth.

Integrating Lean Problem-Solving with Other Methodologies

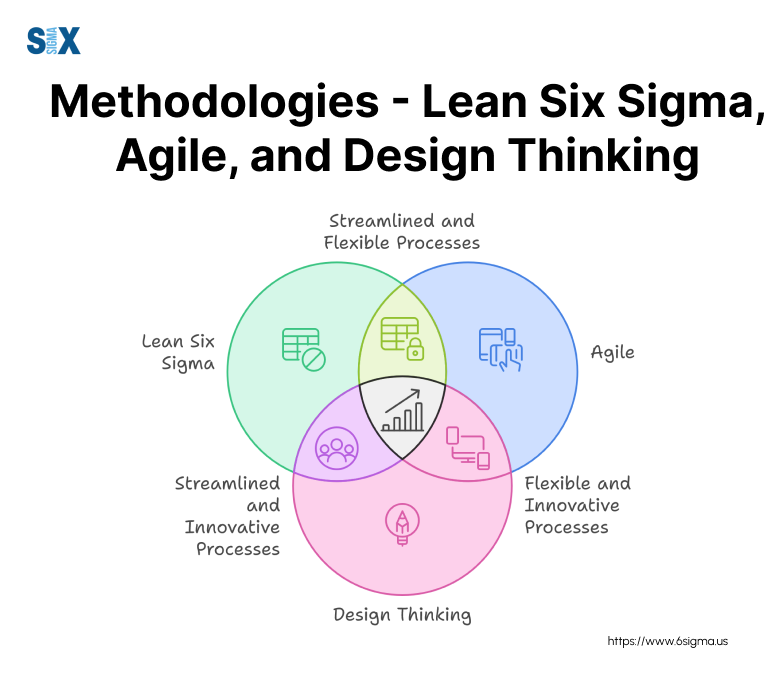

One of the most exciting developments I’ve observed and contributed to is the integration of lean problem-solving with other powerful methodologies. This synergy has led to even more effective and versatile approaches to tackling complex business challenges.

In this section, I’ll share my insights on how lean problem-solving can be combined with other popular methodologies to create robust, holistic problem-solving frameworks. I’ll demonstrate how these integrated approaches can drive unprecedented levels of efficiency and innovation.

Lean Six Sigma

Lean Six Sigma is a methodology I’m particularly passionate about, as it combines the waste-reduction focus of lean with the variation-reduction power of Six Sigma. This integration creates a formidable problem-solving approach that I’ve successfully implemented in numerous organizations.

Key synergies

- Lean’s focus on eliminating waste complements Six Sigma’s emphasis on reducing variation

- Both methodologies prioritize data-driven decision-making

- The DMAIC framework of Six Sigma provides a structured approach to lean problem solving

How to combine effectively

- Use lean tools like Value Stream Mapping to identify areas of waste

- Apply Six Sigma statistical tools to analyze and reduce variation in these areas

- Implement lean solutions and monitor results using Six Sigma control charts

We used this integrated approach to reduce defects in a manufacturing process by 70% while simultaneously increasing throughput by 25%.

Agile

The integration of lean problem-solving with Agile methodologies has revolutionized project management, particularly in software development and IT. As someone who has led numerous international projects, I’ve seen firsthand how this combination can dramatically improve project outcomes.

Key synergies

- Both emphasize iterative improvement and flexibility

- Agile’s sprint cycles align well with Lean’s PDCA (Plan-Do-Check-Act) cycle

- Both methodologies prioritize customer value

How to combine effectively

- Use lean problem-solving techniques like the 5 Whys in sprint retrospectives

- Implement lean visual management tools like Kanban boards in Agile workflows

- Apply lean waste reduction principles to streamline Agile processes

During a project, we integrated lean problem-solving into their Agile development process, resulting in a 30% reduction in time-to-market for new products.

Design Thinking

Design Thinking, with its focus on user-centric innovation, can be powerfully enhanced by lean problem-solving techniques. This combination has proven particularly effective in my work with product development teams.

Key synergies

- Both methodologies emphasize understanding user needs

- Lean’s efficiency focus complements Design Thinking’s innovation emphasis

- Both approaches encourage prototyping and iterative improvement

How to combine effectively

- Use lean problem-solving tools like the Fishbone Diagram in the Define stage of Design Thinking

- Apply lean principles to streamline the prototyping process in Design Thinking

- Incorporate lean metrics into the testing phase of Design Thinking

At a computer hardware and software manufacturer, we integrated lean problem-solving into their Design Thinking process, leading to a 40% reduction in product development cycle time and a significant increase in customer satisfaction scores.

This diagram highlights the key principles shared by lean problem solving, Six Sigma, Agile, and Design Thinking, as well as their unique contributions. By understanding these intersections, you can create a tailored problem-solving approach that leverages the strengths of each methodology.

Measuring Success and ROI of Lean Problem Solving

I’ve learned that implementing lean problem-solving techniques is only half the battle. The other crucial half is measuring the success and demonstrating the return on investment (ROI) of these initiatives.

I’ve developed robust methods for quantifying the impact of lean problem-solving efforts. In this section, I’ll share my insights on how to effectively measure and communicate the value of your lean problem-solving initiatives.

Key Performance Indicators (KPIs)

Selecting the right KPIs is crucial for tracking the success of your lean problem solving efforts. Based on my experience, here are some essential metrics to consider:

- Cycle Time: Measures the time taken to complete a process from start to finish.

- First Time Yield: Tracks the percentage of units produced correctly the first time without rework.

- Defect Rate: Monitors the number of defects per million opportunities (DPMO).

- Cost of Poor Quality (COPQ): Quantifies the costs associated with producing defective products or services.

- Employee Engagement: Measures the level of employee involvement and satisfaction with the lean problem-solving process.

We implemented these KPIs to track our lean manufacturing problem-solving initiatives. This allowed us to demonstrate a 30% reduction in cycle time and a 25% improvement in first-time yield within the first year of implementation.

Calculating ROI

Calculating the ROI of lean problem-solving initiatives is essential for gaining and maintaining stakeholder support. Here’s a simple formula I’ve used successfully:

ROI = (Gains from improvement – Cost of improvement) / Cost of improvement x 100%

To effectively calculate ROI:

- Quantify all costs associated with the lean problem-solving initiative, including training, tools, and time investment.

- Measure the financial gains from improvements, such as reduced waste, increased productivity, or higher quality output.

- Use the formula to calculate the percentage return on your investment.

For example, in a project, we invested $500,000 in lean problem solving training and implementation. The resulting improvements led to annual savings of $2 million. Using our formula:

ROI = ($2,000,000 – $500,000) / $500,000 x 100% = 300%

This compelling 300% ROI helped secure ongoing support for our lean initiatives from top management.

Long-term Impact Assessment

While immediate results are important, the true value of lean problem-solving often manifests in long-term benefits. Here are some approaches I’ve used to assess long-term impact:

- Trend Analysis: Track KPIs over extended periods to identify sustained improvements.

- Cultural Shifts: Assess changes in organizational culture, such as increased employee problem-solving capabilities and proactive improvement mindsets.

- Competitive Advantage: Evaluate market share gains or improved customer satisfaction over time.

Remember, measuring the success and ROI of lean problem-solving is not just about numbers. It’s about telling a compelling story of continuous improvement and value creation.

By effectively tracking KPIs, calculating ROI, and assessing long-term impact, you can demonstrate the tangible benefits of lean problem-solving to all stakeholders in your organization.

Take your problem-solving and leadership skills to the highest level and become a catalyst for organizational transformation. Enroll in our Lean certification programs today!

The Future of Lean Problem Solving

Now, as we look ahead, I see transformative changes on the horizon that will reshape how we approach problem-solving in the coming years.

Integration with AI and Big Data

The convergence of lean problem-solving techniques with artificial intelligence and big data analytics is perhaps the most significant trend I’m observing. This integration is set to revolutionize how we identify, analyze, and solve complex business problems.

Key developments

- Predictive Problem Solving: AI algorithms can anticipate potential issues before they occur, allowing for proactive problem-solving.

- Enhanced Root Cause Analysis: Machine learning can process vast amounts of data to identify patterns and root causes that might be invisible to human analysts.

- Automated Lean Tools: AI-powered versions of traditional lean tools like the 5 Whys or Fishbone Diagrams can provide deeper insights and suggestions.

In a recent project with a major tech company, we implemented an AI-driven lean problem solving system that reduced defect rates by 40% and improved overall equipment effectiveness by 25%.

Adapting to Remote and Hybrid Work Environments

The shift towards remote and hybrid work models is challenging traditional lean problem-solving processes. However, it’s also opening up new opportunities for innovation and efficiency.

Emerging trends

- Virtual Lean Problem Solving Boards: Digital platforms that replicate the functionality of physical boards, enabling real-time collaboration across distributed teams.

- Remote Gemba Walks: Using augmented reality (AR) technology to conduct virtual site visits and observations.

- Asynchronous Problem Solving: Developing lean problem-solving methods that accommodate different time zones and work schedules.

During the pandemic, I helped a manufacturing client implement a virtual lean problem solving process that maintained productivity levels despite having 70% of their workforce remote.

Sustainability and Environmental Considerations

As the global focus shifts toward sustainability, lean problem solving is evolving to incorporate environmental considerations into its core principles.

Key developments

- Green Value Stream Mapping: Incorporating environmental impact metrics into traditional value stream maps.

- Circular Economy Problem Solving: Applying lean techniques to design waste out of systems and promote recycling and reuse.

- Carbon Footprint Reduction: Using lean problem solving methods to optimize processes for minimal environmental impact.

In problem-solving with an automotive supplier, we used Lean Six Sigma problem-solving techniques to reduce their carbon footprint by 30% while simultaneously improving production efficiency.

To prepare for these future developments, I recommend

- Investing in AI and data analytics training for your lean practitioners

- Developing digital literacy skills across your organization

- Incorporating sustainability metrics into your lean problem-solving processes

As we navigate these exciting developments, it’s clear that the core principles of lean problem solving – eliminating waste, focusing on customer value, and continuous improvement – will remain as relevant as ever. The challenge and opportunity lie in adapting these principles to new technologies and global priorities.

Conclusion

As we wrap up this comprehensive exploration of lean problem-solving, I’m reminded of a pivotal moment early in my career.

At an industrial manufacturing organization, we were facing a seemingly insurmountable manufacturing challenge, and it was through the application of lean problem-solving techniques that we not only overcame the issue but revolutionized our entire production process.

This experience solidified my belief in the power of lean methodologies, a belief that has only grown stronger over my 20 years as a Six Sigma Master Black Belt.

The value of lean problem-solving cannot be overstated. It provides a structured, data-driven approach to tackling complex challenges, driving continuous improvement, and fostering a culture of innovation.

As we’ve seen, lean problem-solving is not just a set of tools or techniques – it’s a mindset. It’s about seeing opportunities for improvement in every process, empowering every team member to contribute to problem-solving efforts, and never being satisfied with the status quo. This mindset, when fully embraced, can transform not just individual processes, but entire organizations.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs