Lean Master

Lean Master program provides candidates with a thorough working knowledge of principles of Lean

6Sigma.us‘ Lean Master is the final step in our Lean Training Program. Our Lean Master classes are offered In-Person and Live Instructor-Led, as well as Onsite at your location. Please check back for the expansion of the Lean Master to other locations and dates. If you are sending more than ten employees to a training session, look into our onsite programs.

“Lean Master” Certification Program Requirements:

- Must complete Lean Fundamentals (or similar) prior to enrollment

- Must complete at least 3 Projects (Lean Projects, Kaizen events, DMAIC, completed A3s) (If you have questions about the project requirements, please contact us.)

- 1 of these should be completed prior to enrollment

Course Outline – Lean Master

Our Lean Virtual Instructor-led and Group Training courses cover the following topics:

* The training for this program is available for manufacturing and service (transactional) based companies. The agenda and examples for both options are available

Topics covered:

- Brief review of Lean Fundamentals

- Train-the-Trainer: how to effectively transfer lean knowledge

- Advanced Value Stream Mapping (Present and Prospective State)

- Kaizen Events – the next level

- SMED: Rapid Changeover

- Machine Kanban: Pull in a machine shop

- Heijunka: leveling out fluctuation

- Change Leadership/Change Management

- Lean Accounting

Virtual Instructor-led Training

See the schedule for upcoming classes!

Group Training

Provided either at site or live virtually

At the end of this course, the attendees will:

Upon completion of this program, students should:

- Be in a position to guide Lean Agents

- Possess the necessary skills to utilize Lean methodologies and figures to decrease expenses, reduce cycle times, increase volume, and improve production in Service, Supply Chain, Manufacturing, and Operations

- Have a deeper knowledge of basic lean tools

- Have the skills required to apply advanced lean tools

- Be able to expand their abilities as professionals so that they are able to share their unique projects, perspectives, and experience

- Be able to analyze value stream maps in greater depth

- Have had a chance to talk over particular elements of concern and projects with experienced trainers to begin on an established road for success

- Be able to provide direction, analysis, and reporting for projects and how they tie to organizational strategic initiatives

- Know the fundamentals of change leadership/change management and how to overcome opposition to spearhead a successful deployment

This program course is the Final Lean Level, in which you will learn to apply several continuous improvement techniques such as TPM, SMED, the ABC Analysis, learn to differentiate between types of Pull Systems, apply Change Management, and of course how to successfully continue to lead Kaizen Events as a facilitator. The final goal of the Lean Masters program is to allow you to create a strong culture in your organization that follows the 5 Principles of Lean.

As an IACET, PMI, and SHRM Accredited Provider, 6Sigma.us offers IACET CEUs, PMI PDUs, and SHRM PDCs for its learning events. (PMI and the PMI Registered Education Provider logo are registered marks of the Project Management Institute, Inc.).

The Role of a Lean Master

A lean master is more than just a title; it’s a commitment to excellence and continuous improvement. Your primary responsibility will be to drive organizational efficiency through the application of lean principles and methodologies.

You’ll be the architect of change, tasked with:

- Identifying inefficiencies and waste in processes

- Developing and implementing lean strategies

- Training and mentoring teams in lean practices

- Leading complex improvement projects

The lean master certification is a testament to our expertise and dedication to these principles. It’s not just about knowing the theory; it’s about applying it effectively in real-world scenarios.

The Strategic Importance of Lean Masters in Organizations

Lean masters can revolutionize operations. They’re not just problem-solvers; they’re strategic assets that can significantly impact an organization’s bottom line.

Lean masters drive organizational efficiency by:

- Streamlining processes to reduce waste and increase productivity

- Fostering a culture of continuous improvement

- Aligning lean initiatives with overall business strategy

- Enhancing customer satisfaction through improved quality and delivery

Key Skills and Competencies

Becoming a lean master requires a unique blend of technical knowledge and soft skills. The core competencies include:

- Deep understanding of lean methodologies and principles

- Strong analytical and problem-solving skills

- Excellent communication and leadership abilities

- Adaptability and innovative thinking

- Project management expertise

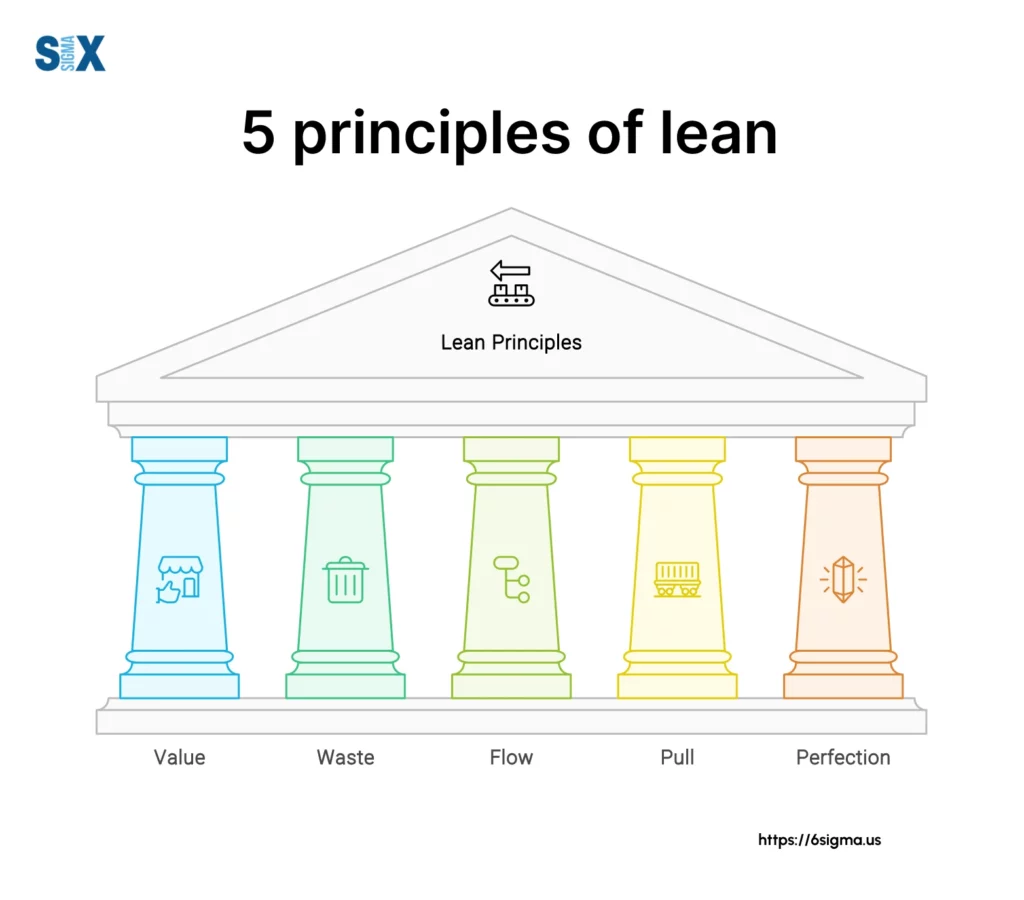

Core Principles of Lean Methodology

The core principles of lean methodology can revolutionize organizations. These principles are the bedrock of lean thinking and are crucial for any aspiring lean master to understand and apply.

The Five Principles of Lean

The principles of lean are the foundation upon which all lean methodologies are built. Mastering these five principles is essential for anyone aspiring to become a lean master:

- Identify Value: This is about understanding what the customer truly values.

- Map the Value Stream: This involves visualizing the entire process from start to finish.

- Create Flow: This principle focuses on eliminating bottlenecks.

- Establish Pull: This means producing only what’s needed when it’s needed.

- Seek Perfection: This is about continuous improvement. It’s not about being perfect, but always striving to be better.

Some of the most advanced and impactful aspects of lean methodology lie in effectively transferring knowledge, advanced value stream mapping, and taking Kaizen events to the next level. Here are some insights on these crucial areas.

Train-the-Trainer: How to Effectively Transfer Lean Knowledge

One of the most critical skills for a Lean Master is the ability to effectively transfer lean knowledge to others. This is where the Train-the-Trainer approach becomes invaluable.

- Understand Adult Learning Principles: Adults learn differently from children. They need to see the relevance of what they’re learning and how it applies to their work.

- Use Experiential Learning: Incorporate hands-on exercises. For instance, in a workshop, we used a simulated production line to demonstrate lean principles in action.

- Develop Clear, Concise Materials: Create training materials that are easy to understand and implement. Visual aids, checklists, and step-by-step guides are particularly effective.

- Practice Teaching Sessions: Have trainees teach back what they’ve learned. This reinforces their understanding and helps them develop their training skills.

- Provide Ongoing Support: Learning doesn’t stop after the training. Ensure there’s a support system in place, whether it’s regular check-ins, a mentoring program, or an online forum for questions.

Advanced Value Stream Mapping (Present and Prospective State)

While basic Value Stream Mapping (VSM) is a fundamental lean tool, advanced VSM takes this concept further by not only mapping the present state but also envisioning a prospective future state.

- Present State Mapping: Go beyond just documenting the current process. Incorporate data on variability, quality issues, and capacity constraints.

- Prospective State Mapping: Create multiple future state maps, each representing different scenarios and levels of improvement. This allows you to set both short-term and long-term goals.

- Dynamic Modeling: Use simulation software to create dynamic models of your value streams. This allows you to test different improvement scenarios virtually before implementing them.

- Cross-Functional Integration: Map not just the core process, but also supporting processes like maintenance, quality control, and supply chain. This will give you a more holistic view of the entire system.

- Technology Integration: Incorporating emerging technologies like IoT and AI could impact the future state, allowing for more innovative and forward-thinking improvements.

Kaizen Events – The Next Level

Kaizen events are a cornerstone of lean methodology, but taking them to the next level can yield even more impressive results.

- Extended Kaizen: Instead of traditional 3-5 day events, experiment with extended Kaizen over several weeks. This allows for more thorough analysis and implementation of complex changes.

- Virtual Kaizen: With the rise of remote work, you need developed methodologies for conducting effective virtual Kaizen events. This allows global participation and cross-site improvements.

- Kaizen Blitz: For urgent issues, use Kaizen Blitz – a hyper-focused, intensive improvement event that can yield rapid results.

- Cross-Functional Kaizen: By involving multiple departments in a single Kaizen event, you can tackle complex, organization-wide issues.

- Kaizen Maturity Model: It helps organizations assess and improve their Kaizen capabilities over time, moving from basic problem-solving to transformative innovation.

Lean Master Certification: Pathways to Expertise

Becoming a Lean Master is not just about acquiring a certification; it’s about embarking on a journey of continuous learning and improvement. As you progress, you’ll find that the principles you apply to organizations are equally transformative for your professional growth.

Richard Lynch, Ph.D, Master Black Belt & Program Leader at SixSigma.us

The landscape of lean master certification programs is diverse, reflecting the multifaceted nature of lean methodologies.

Now, let’s dive into the Lean Master certification process.

Training Options

When it comes to Lean Master training, you have several options:

Virtual Instructor-led: For those who prefer live training, but from the convenience of your office or home, this is the go-to option. The best part, you learn via an interactive seminar with other professionals, taught by certified Master Black Belt. Check out our current training schedule.

Live Private Training: if you are looking to train multiple employees, we can also deliver at your site or private virtual.

Choosing the right lean master certification program depends on your industry and career goals. We often advise professionals to align their certification choices with their specific needs.

Lean Implementation Strategies

Implementing lean methodologies is not a one-size-fits-all process. Here’s a strategic approach that has proven successful across diverse organizational contexts:

- Assessment and Goal Setting

Begin with a thorough assessment of the current state. Mapping out existing processes and identifying areas of waste. Set clear, measurable goals aligned with the organization’s strategic objectives.

- Leadership Buy-in and Cultural Shift

Lean implementation starts at the top. Spend time educating the C-suite on lean principles. This top-down approach is crucial for fostering a lean culture throughout the organization.

- Employee Engagement and Training

Empower employees at all levels. Make every employee a problem solver. This approach leads to remarkable innovations, even in unexpected areas.

- Start with Pilot Projects

Begin with small, manageable projects to demonstrate value. Start by optimizing a single department. This will pave the way for organization-wide implementation.

- Continuous Improvement Cycles

Implement PDCA (Plan-Do-Check-Act) cycles. This iterative approach ensures ongoing refinement and adaptation of lean processes.

Common Challenges

The biggest challenge in implementing lean is not the technical aspects, but the human element. Success lies in transforming resistance into engagement, silos into collaboration, and data overload into focused action. As a Lean Master, your role is to be the catalyst that turns these challenges into opportunities for continuous improvement.

Peter Peterka, Master Black Belt & President, SixSigma.us

Challenges to organizational efficiency are some common hurdles and strategies to overcome them:

- Resistance to Change

Challenge: Employees often resist new methodologies.

Solution: Focus on communication and involvement within each department to facilitate acceptance.

- Lack of Sustained Commitment

Challenge: Initial enthusiasm wanes over time.

Solution: Regularly showcase wins and tie lean initiatives to strategic goals.

- Misalignment with Organizational Goals

Challenge: Lean initiatives sometimes seem disconnected from business objectives.

Solution: Always align lean projects with strategic goals.

- Data Overload

Challenge: Too much data can be overwhelming.

Solution: Focus on key metrics.

- Silos and Lack of Cross-functional Collaboration

Challenge: Departments often work in isolation.

Solution: Implement cross-functional lean teams to foster collaboration.

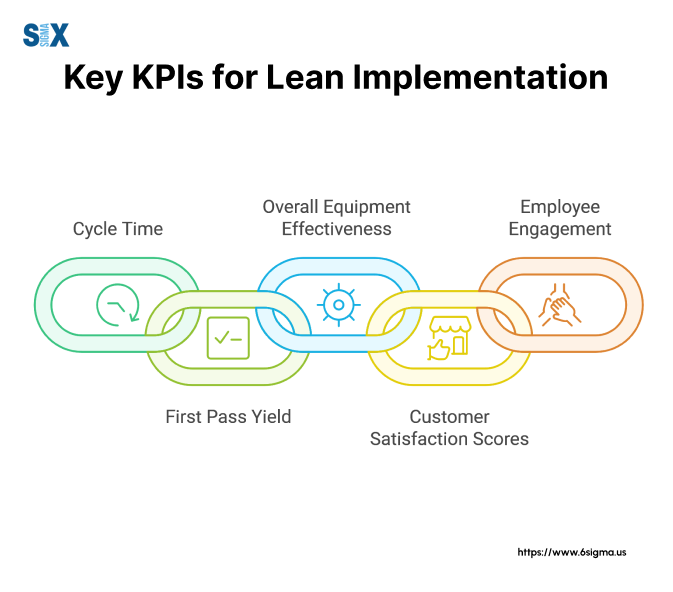

Effective measurement is crucial for process improvement. Here are key KPIs to consider:

- Cycle Time

Measures the time from the start to the end of a process.

- First Pass Yield

Tracks the percentage of units made correctly the first time, without rework.

- Overall Equipment Effectiveness (OEE)

Combines availability, performance, and quality metrics.

- Customer Satisfaction Scores

Lean isn’t just about internal efficiency; it’s about delivering value to the customer. Regular customer feedback surveys are crucial.

- Employee Engagement

Measures the level of employee involvement in lean initiatives. High employee engagement correlates strongly with successful lean implementations.

- Cost Savings

Quantifies the financial impact of lean initiatives.

- Lead Time

Measures the time from customer order to delivery.

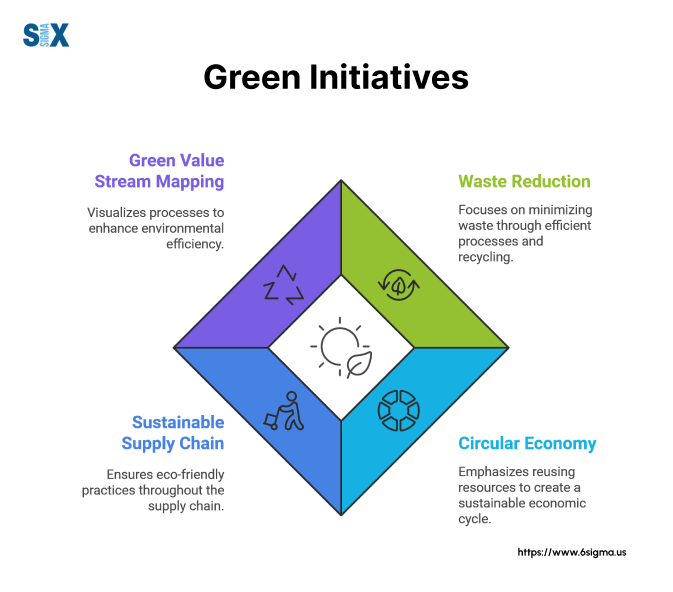

Lean and Sustainability: Green Initiatives

Sustainability is becoming increasingly intertwined with lean principles, driving organizational efficiency in new ways. There is a powerful synergy between lean and green initiatives:

- Waste Reduction Beyond Production

Lean principles are now being applied to reduce environmental waste.

- Circular Economy Concepts

Lean is evolving to encompass the entire product lifecycle.

- Sustainable Supply Chain Management

Lean principles are being extended to create more sustainable supply chains.

- Green Value Stream Mapping

This innovative tool incorporates environmental impacts into traditional value stream maps.

The integration of sustainability into lean practices isn’t just good for the environment; it’s good for business. Companies that embrace this integration often see improved efficiency, reduced costs, and enhanced brand value.

Global Perspectives on Lean

The future of lean mastery is increasingly influenced by diverse cultural perspectives:

- Adaptation of Lean Principles

Different cultures interpret and apply lean principles in unique ways.

- Cross-Cultural Lean Teams

Global companies are forming diverse lean teams to leverage varied perspectives.

- Localization of Lean Training

Lean master programs are being tailored to local contexts.

- Global Best Practice Sharing

There’s an increasing trend of international lean conferences and forums.

- Lean in Emerging Markets

Emerging economies are rapidly adopting lean principles, often leapfrogging traditional implementation stages.

The future of lean is global, diverse, and increasingly interconnected. As an upcoming lean master, you must be prepared to adapt your approaches to different cultural contexts while maintaining the core principles of lean.

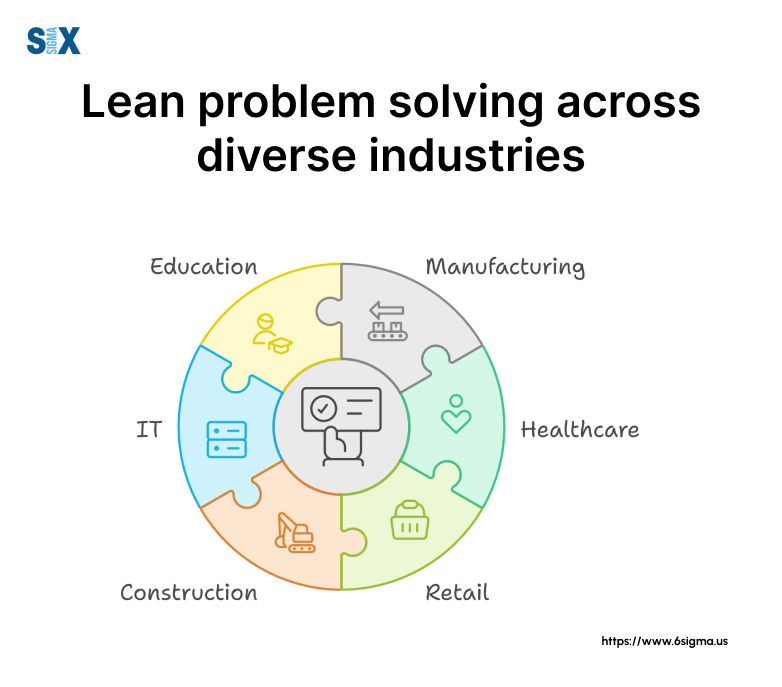

Industries Seeking Lean Expertise

Lean management principles are applied across a wide spectrum of industries. The demand for lean expertise is more diverse than ever.

The versatility of lean principles means that lean masters can find exciting opportunities across various sectors, applying their skills to diverse challenges.

Stay ahead of the curve and drive value in your organization as a certified Lean professional.

Start your Lean Master training & certification today!

-

It seems to give me the information that I need.

Thomas Miller |

5

-

The material was very good, very useful and presented extremely well. I especially enjoyed the effort expended by six sigma and my instructor, they customized the course for me and I had a one to one ratio of students to teacher. I am very grateful and

Sean Flanigan |

5

-

David was always very clear in his presentations, took time to answer my questions, and assisted me when I needed help. The class was very enjoyable!

Kristin Sauer |

5

-

Well explained ABC process and calculations, Replenishment pull, 2 Bin calculations, Batch sizing calculations

Alaster Nyaude |

5

-

Relevant to my role and unique training that I was not able to find anywhere else.

Nancy Beth English |

5

Training Schedule

Lean Master

[

]

Lean Master

[

]

Lean Master

[

]

Lean Master

[

]