Lean Introduction

Lean Introduction program provides candidates with a comprehensive overview of the principles of Lean Thinking.

6Sigma.us’ Lean Introduction program provides a comprehensive overview of the principles of Lean Thinking and introduces the principles of Lean and the overall importance of focusing on what adds value to the customer.

Course Outline – Lean Introduction

Our Lean Introduction course covers the following topics:

- Lean Concepts and Lean Six Sigma

- Principles of Lean and A3 Thinking

- Kaizen

- Foundation of Lean – Waste

- Lean Case Studies

At the end of this course, the attendees will:

- Understand that Lean and Six Sigma are highly complementary methodologies that work better together than alone. We offer the full scope of Lean and Six Sigma training and implementation support.

- Have a basic understanding of the core concepts of Lean Thinking, be able to identify wastes in your processes, and learn how to set up and conduct a kaizen event

- Understand that Lean and Six Sigma are highly complementary toolsets, with a basic understanding of when and how to bring the two methodologies together to drive quick, breakthrough results

- Opportunity to discuss project ideas with knowledgeable instructors

As an IACET, PMI, and SHRM Accredited Provider, 6Sigma.us offers IACET CEUs, PMI PDUs, and SHRM PDCs for its learning events. (PMI and the PMI Registered Education Provider logo are registered marks of the Project Management Institute, Inc.).

Lean Introduction Training & Certification Process

Now, let’s dive into the Lean Introduction certification process.

Training Options

When it comes to Lean Fundamentals training, you have several options:

Online Courses: We offer comprehensive online courses that allow you access 24/7 to learn at your own pace. This flexibility is perfect if you have a busy schedule.

Live Private Training: if you are looking to train multiple employees, we can also deliver at your site or private virtual.

Stay ahead of the curve and drive value in your organization as a certified Lean professional.

Start your Lean Introduction training & certification today!

What is Lean?

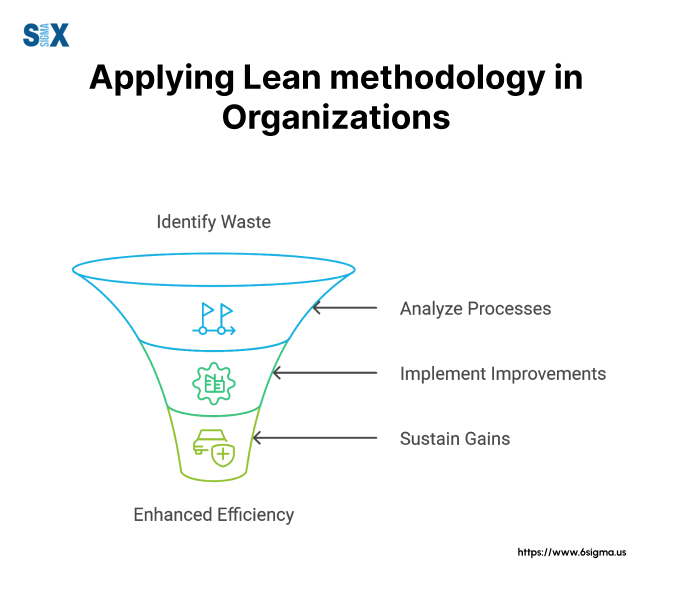

At its core, lean is a systematic approach to identifying and eliminating waste in processes while maximizing customer value.

It’s not just a set of tools, but a way of thinking that permeates every aspect of an organization.

Core Principles of Lean

The lean methodology is built on five fundamental principles aimed at driving significant improvements in countless organizations:

- Identify Value: This is where it all begins. We must understand what the customer truly values and is willing to pay for. This step helps in aligning organizational efforts with customer needs.

- Map the Value Stream: This involves visualizing the entire process from start to finish, and identifying steps that add value and those that don’t.

- Create Flow: Once we’ve identified value and mapped the stream, we work to ensure a smooth, uninterrupted flow of products or services. This often involves breaking down silos between departments.

- Establish Pull: This principle ensures we produce only what’s needed when it’s needed. It’s about responding to customer demand rather than pushing inventory.

- Seek Perfection: This is about continuous improvement. It’s not about achieving perfection, but rather fostering a culture of ongoing refinement.

The Lean Philosophy

Beyond these principles, lean is underpinned by a philosophy that shapes how organizations operate:

- Customer-centric Approach: Everything we do in lean is geared towards delivering value to the customer.

- Continuous Improvement Mindset: Known as ‘Kaizen’ in lean terminology, this is about making small, incremental improvements every day.

- Respect for People: Lean recognizes that the people doing the work are best positioned to improve it. This principle fosters employee engagement and innovation.

The lean methodology, with its principles and philosophy, forms the foundation of a lean system. It’s an introduction to lean that goes beyond mere concepts, providing a roadmap for practical implementation.

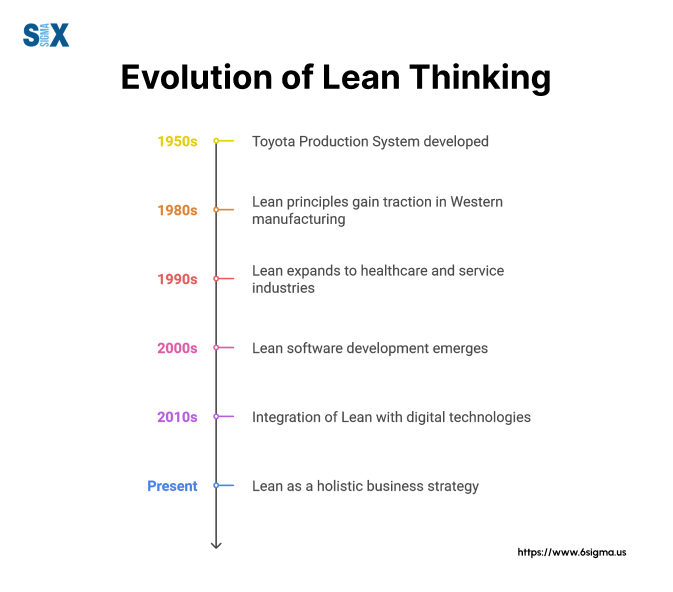

The Evolution of Lean Thinking: From Manufacturing to Beyond

Lean started as a manufacturing-focused methodology and has evolved into a versatile approach that’s transforming industries across the board. Let’s look at the journey through the history and expansion of lean thinking.

Toyota and the birth of Lean

The story of Lean begins in post-World War II Japan. Toyota, facing fierce competition and resource constraints, developed what we now know as the Toyota Production System (TPS).

Taiichi Ohno, often called the father of TPS, identified seven types of waste (muda) that hindered productivity. This lean concept of waste reduction became the cornerstone of the lean methodology.

Expansion beyond manufacturing

What’s truly fascinating about lean thinking is how it has transcended its manufacturing roots. We’ve had the opportunity to apply lean principles across various sectors, and the results have been consistently impressive.

Lean in the digital age

The introduction to lean methodology in the digital age is about more than just efficiency; it’s about agility and responsiveness. Companies that embrace lean thinking are better positioned to adapt to rapid market changes and disruptive technologies.

Whether you’re in manufacturing, healthcare, tech, or any other field, lean thinking offers a powerful framework for driving efficiency and creating value.

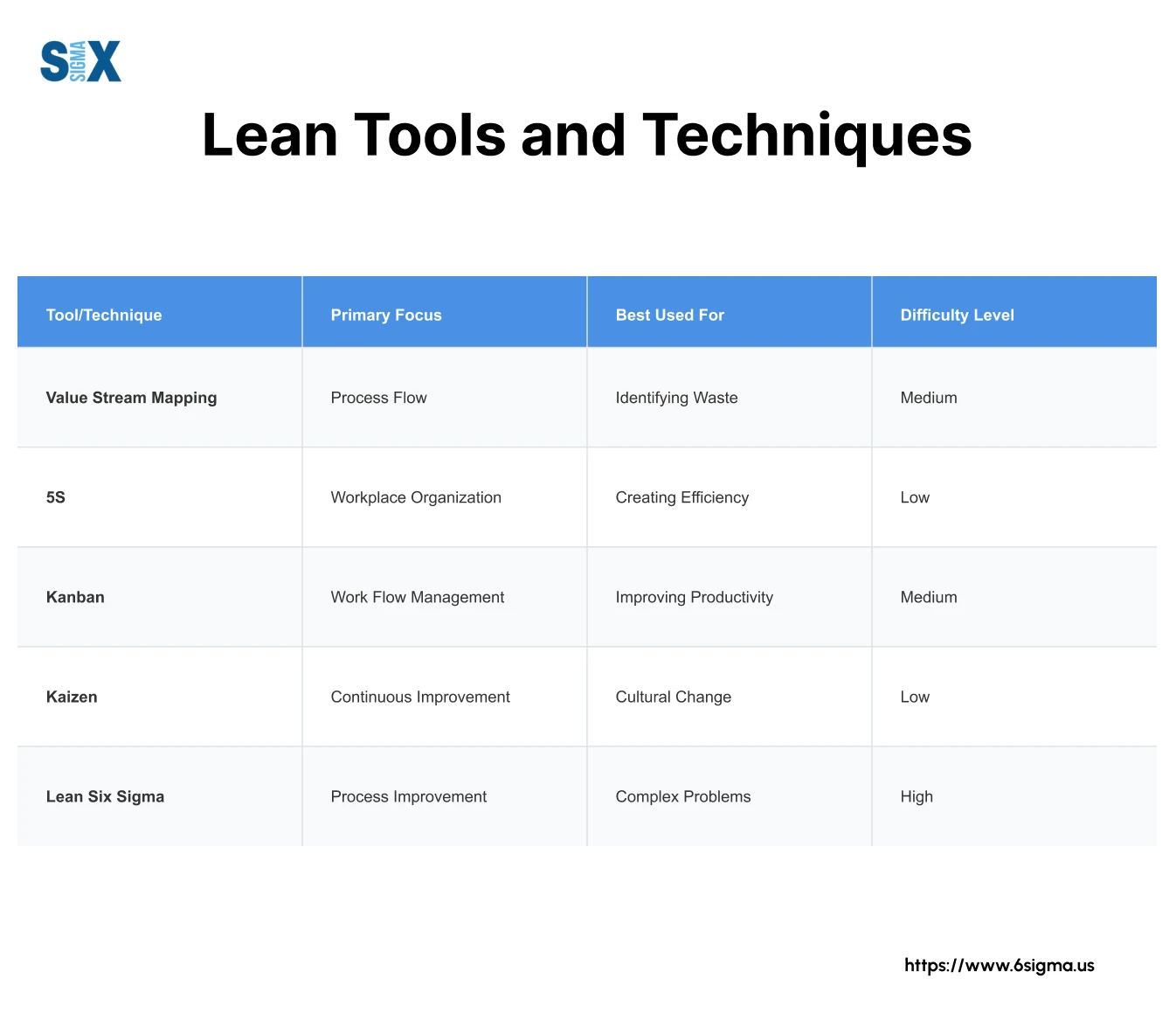

Lean methodology has various tools and techniques to deliver consistent results and drive overall growth and efficiency. Let’s look at some essential ones.

Value Stream Mapping (VSM)

Value Stream Mapping is like having a GPS for your processes. It’s a visual tool that helps you see the flow of materials and information as a product or service makes its way to the customer.

Key benefits of VSM:

- Identifies waste and bottlenecks

- Provides a common language for process improvement

- Helps prioritize improvement efforts

5S Methodology

The 5S methodology is the backbone of creating a lean workplace. It’s a systematic approach to workplace organization. The principles of 5S are:

- Sort (Seiri)

- Set in Order (Seiton)

- Shine (Seiso)

- Standardize (Seiketsu)

- Sustain (Shitsuke)

Kanban

Kanban, which means “signboard” in Japanese, is a visual management tool that helps control the flow of work. Kanban boards revolutionize everything from software development at Intel to inventory management.

Benefits of Kanban:

- Improves workflow visibility

- Reduces overproduction and inventory

- Enhances team collaboration

Kaizen

Kaizen, or continuous improvement, is the heart of lean thinking. It’s not just a tool, but a philosophy that encourages everyone to suggest and implement small, incremental improvements.

Six Sigma and Lean Six Sigma

While Lean focuses on eliminating waste, Six Sigma aims to reduce variation. Together, they form a potent methodology for process improvement.

The key to success with these lean techniques is not just understanding them, but knowing how to apply them in your specific context. In our training, we always emphasize that these tools are means to an end – the end being a more efficient, value-driven organization.

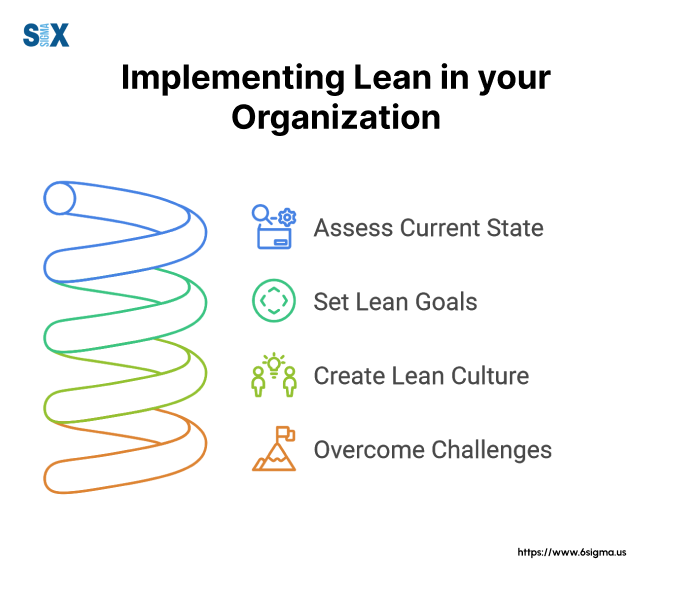

Implementing Lean in a Practical Way

Implementing lean in your organization can be tricky. Here are some practical steps on how you can actively implement lean techniques in your organization.

Assessing your current state

The first step in any lean process is to understand where you are.

Key assessment techniques:

- Value Stream Mapping (as discussed earlier)

- Gemba Walks (going to the actual place of work)

- Employee surveys and interviews

- Process capability studies

Pro tip: Be prepared for surprises. The most valuable insights often come from areas you least expect.

Setting Lean goals

Once you have a clear picture of your current state, it’s time to set goals. To implement lean methods, use the SMART framework:

- Specific: “Reduce order processing time by 30%”

- Measurable: Use clear metrics

- Achievable: Set challenging but realistic targets

- Relevant: Align with overall business objectives

- Time-bound: Set a deadline for achievement

Remember, lean is about continuous improvement. Start with achievable goals and build momentum.

Creating a Lean culture

Implementing lean techniques is only half the battle. The real challenge lies in creating a lean culture.

- Leadership commitment: Ensure top management is visibly supportive

- Employee empowerment: Encourage everyone to suggest improvements

- Training and education: Provide ongoing lean learning opportunities

- Celebration of successes: Recognize and reward lean achievements

Overcoming common challenges

The path to a lean workplace is never smooth. Here are some common obstacles and how to overcome them:

- Resistance to change: Address fears and communicate benefits clearly

- Lack of resources: Start small and demonstrate ROI to secure more resources

- Inconsistent application: Develop standard work procedures and audit regularly

- Loss of momentum: Celebrate quick wins and maintain regular lean events

Wherever you are in your lean readiness, there’s always room for improvement. The key is to start where you are and continuously strive for better.

Integrating Lean with Other Methodologies

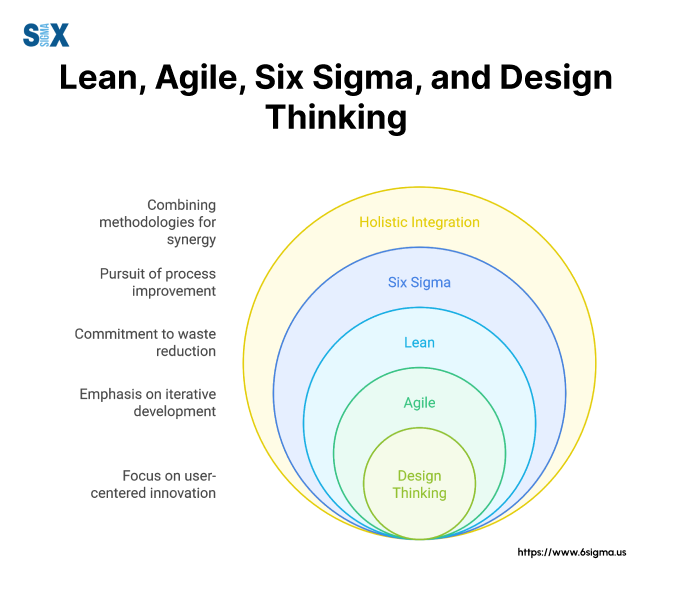

This synergy often leads to breakthrough improvements that surpass what any single approach can achieve. Let’s explore how lean integrates with other popular methodologies to create robust, flexible systems for continuous improvement.

Lean and Agile

Lean and Agile share a common ancestor in the Toyota Production System, but they’ve evolved to serve different purposes. While lean focuses on eliminating waste and improving flow, Agile emphasizes flexibility and rapid iteration in product development.

Key synergies:

- Lean’s focus on eliminating waste complements Agile’s emphasis on delivering customer value quickly

- Both methodologies promote continuous improvement and adaptability

Lean and Six Sigma

Lean focuses on flow and waste reduction, Six Sigma targets variation reduction and process control. Together, they form a comprehensive approach to process improvement called “Lean Six Sigma“.

Key synergies:

- Lean’s waste reduction complements Six Sigma’s variation reduction

- Both methodologies use data-driven decision-making

Lean and Design Thinking

Design Thinking, with its focus on user-centered innovation, might seem at odds with Lean’s efficiency-driven approach. Combining these methodologies can lead to game-changing innovations that are both user-friendly and efficiently produced.

Key synergies:

- Design Thinking’s user focus complements Lean’s customer value emphasis

- Both methodologies encourage experimentation and learning

In today’s complex business environment, no single methodology has all the answers. The real power lies in intelligently combining approaches like Lean, Six Sigma, Agile, and Design Thinking to create tailored solutions for each unique challenge.

Peter Peterka, Master Black Belt & President, SixSigma.us

As we integrate these methodologies, it’s crucial to remember that the goal isn’t to rigidly apply every tool from each approach. Instead, the key is to understand the principles behind each methodology and apply them flexibly to your specific context.

-

The simplicity! Ivan lead the course using examples of our daily tasks, making it easier to follow and to engage to the lecture.

Romina Torales |

5

-

The instructor kept the material very interesting and relatable to our industry. He is a great teacher.

Karen Adams |

5

-

I really enjoyed all of the course but especially enjoyed the group activities.

Margaret Rodriquez |

5

-

Ivan was a great instructor. He kept the class engaged in the subject.

Stacy Burton |

5

-

I was glad to see that we are looking into way to be more effective in how we work. I have also been a firm believer in trimming some steps that are not needed. This course puts a name on it, shows us how to identify and a road map to eliminate these proc

Scott Carlson |

5

-

Jaclyn was awesome. She kept the training moving at a fast, entertaining and engaging pace. Examples used were real life scenarios that we could learn from.

Pamela Summers |

5

-

Jaclyn does a fabulous job; she has a sense of humor and can also get us "back on track" when needed. She makes the course work fly by and ensures we understand the material.

Nancy Tank |

5

-

Jaclyn is a great instructor. Six Sigma training has helped me to change my mind set about how we do some things here.

Carol Nienhaus |

5

-

Jaclyn is very helpful and encourages participation.

Stacey Thorsten |

5

-

Practical, hands-on training that can be used for numerous applications

Vicki Katzfey |

5