Maximizing Customer Value: How Reducing Lean Waste Improves Customer Satisfaction and Loyalty

Customer satisfaction is every business’s end goal. Companies must keep customers happy to generate more revenue and build a valuable long-term brand. Lean waste reduction is one of the best strategies for improving customer satisfaction, as it enables you to cut down unnecessary processes, boost turnaround time, and deliver products at optimal prices.

In this article, we’ll delve into the world of lean techniques and how they can transform your business. By adopting these strategies, you improve customer satisfaction in the short term and also set the stage for long-term success.

What is Lean strategy?

The Lean strategy is not just a buzzword but a powerful business approach. It’s about eliminating every unnecessary part of your production process. It’s a set of techniques that you can apply to identify wasteful processes and the most effective way to reduce or altogether remove them.

Lean techniques were initially developed for the manufacturing sector in the post-World War II era, particularly for automobile manufacturers. The aim was to help manufacturers identify unnecessary processes in their production cycle and reduce or eliminate them to improve customer delivery times. Since then, the lean strategy has spread to many other sectors and made a considerable impact globally. It is now used in banking, software development, retail, restaurants, construction, and virtually every industry that depends on human labor.

Learn more about our Lean training.

Key principles of the Lean strategy

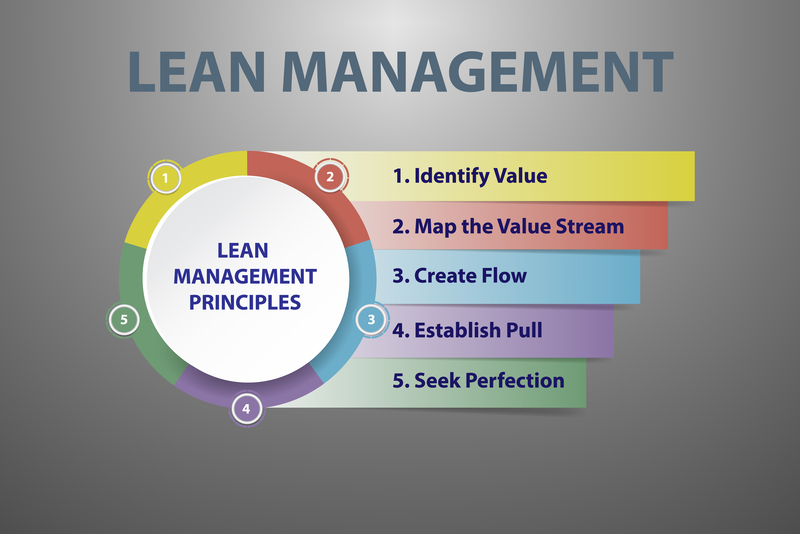

Lean management has five fundamental principles, including:

1. Defining value

The first core principle is identifying value, i.e., the customer’s needs. Remember that the customer is the center of every business process, and you must clearly understand what they want from you. This clear idea helps you evaluate how to meet their needs. You can conduct surveys, technical interviews, and demographic analysis to determine what the customer wants; it’s a rigorous process, not a guessing game.

2. Mapping the value stream

After defining your customer’s value, the next step is to map the value stream. This means identifying all the actions and processes that contribute to creating value for the customer. You’ll use a diagram to showcase all the processes that enable you to convert raw materials into final deliverables, such as design, HR, engineering, customer service, and research.

Your value stream map should ideally be on one page. Upon deeper examination, remove any process that doesn’t add value to the customer, i.e. “waste.”

3. Create flow

After removing waste from the value stream map, it’s time to work with what you have left. Ensure the flow of the remaining processes runs smoothly without delays and bottlenecks. Feel free to reconfigure the processes if needed to make them run smoothly. Everything in the value stream should be in a tight sequence employees can easily follow.

4. Establish Pull

“Pull” implies that the customer can pull the product at any time and collect what you have at the moment. This means you should avoid stocking up on all the inventory ahead of time (in case the customer pulls the product at a specific stage and the other inventory is no longer needed).

A pull-based system requires you to limit your inventory and stock up on only what you need at a specific stage of the production process. It enables just-in-time delivery, wherein products are created precisely when needed and in the required quantities.

5. Continuous improvement

The last principle of continuous improvement is the most important one. It requires you recognizing that there’s always room for improvement in your Lean strategy. Don’t hesitate to change things to improve customer satisfaction and productivity. The aim is to strive towards perfection while delivering value to your customers.

How do I train my employees on the Lean strategy?

Lean strategies are best learned in a formal setting. Some people can learn them independently, but it’s much more complicated than learning them in a structured setting. Here at 6Sigma, we offer Lean training courses for your employees. Our courses provide a comprehensive overview of Lean Thinking principles and empower trainees to develop the vital skills to lead and participate in Lean projects.

We offer Lean training from the basic to the Master level. Employees who complete our courses become certified Lean Agents, improving your company’s standing with clients and partners.

6Sigma’s Lean training programs are designed with the optimal strategy fitting your company’s business objectives and needs. We imbibe theoretical and hands-on knowledge to help your employees become Lean experts and boost your company’s customer satisfaction.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs