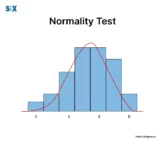

All About Normality Test in Statistical Analysis. Lean Six Sigma

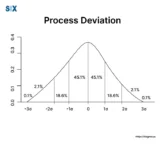

In statistics, the assumption of normality test plays a big role in ensuring results make sense and can be relied on. Many common tests like t-tests, ANOVA, and regression analyses assume data fits under a bell curve shape. Not meeting this assumption can lead to wrong conclusions and beliefs that can’t be trusted. Normality tests […]