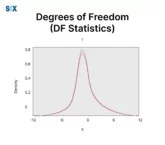

Degrees of Freedom in Statistics. Everything You Need to Know

Degrees of opportunity (df statistics) assume a fundamental part in deciding investigation exactness and legitimacy. Regardless of whether directed speculation tests, fitting relapse models, or exploring information, understanding df statistics is pivotal for drawing educated ends. Degrees of flexibility speak to the measure of figures free to fluctuate amid factual computations. It measures how much […]