Flowchart vs Process Map: Visualizing Workflows Effectively

Deceptively basic in appearance, these diagrams prove invaluable to those seeking streamlined workflows, refined processes, and operational optimizations.

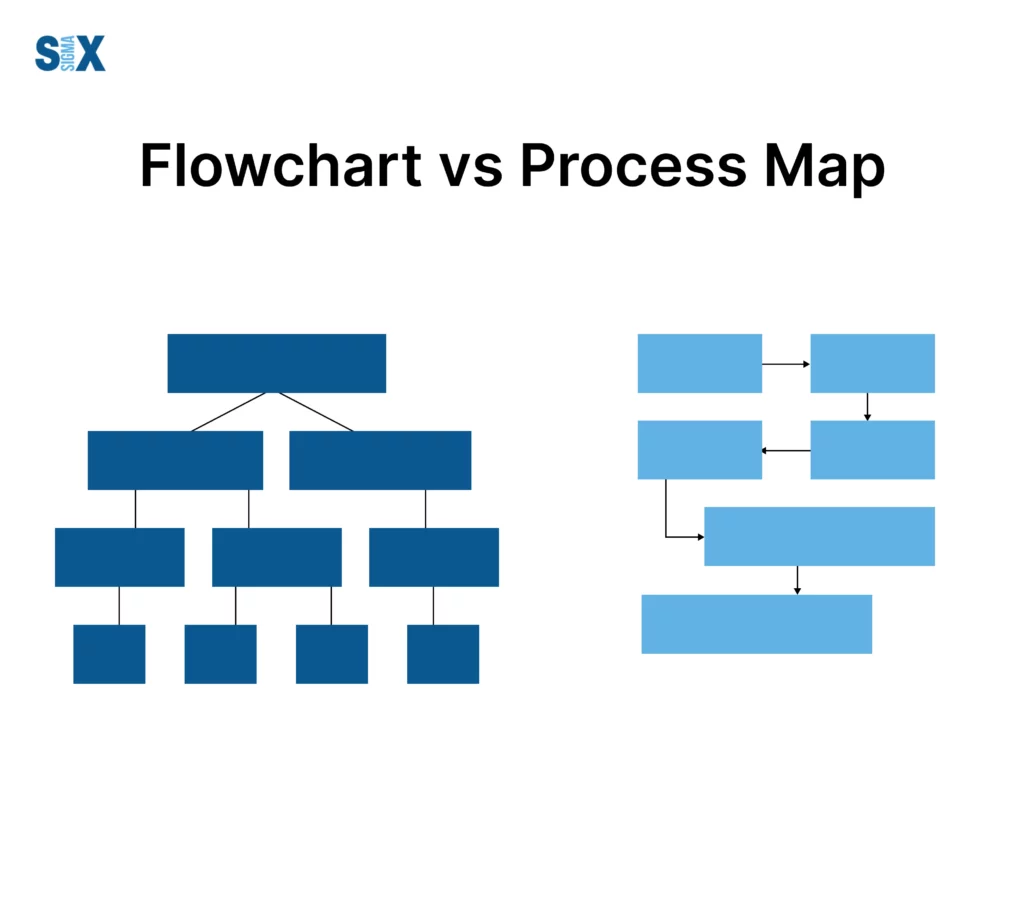

Flowcharts and process maps fulfill analogous functions, translating intricate operations into easy-to-follow, stepwise depictions.

However, as experienced professionals, discerning the subtleties distinguishing these aids matters greatly. Likewise, their singular gifts where purposefully applied hold importance.

We explore flowcharts and mapping tools’ usefulness in navigating complexity strategically. Regardless of field, ponder where visualization enlightens problem-solving or advancement.

The goal in explaining proven sense-makers lies in equipping all with tools for progressing domains advantageously on journeys towards excellence.

Key Highlights

- Flowchart vs Process Map – A comprehensive exploration of the key differences between these two visual tools

- From software development to engineering marvels – An in-depth look at the versatility of flowcharts, showcasing their applications in diverse fields

- Using process maps for operational excellence: From manufacturing to quality management.

- A strategic decision – Actionable insights to help you determine when to leverage flowcharts versus process maps, ensuring you select the most appropriate tool for your specific needs and objectives.

Understanding Flowchart vs Process Map

Effective visualization is the cornerstone of driving operational excellence. Flowcharts and process maps, two powerful visual tools, have been instrumental in my work with global corporations and government institutions alike.

While these diagrams share a common goal of translating complex procedures into easy-to-grasp representations, it’s crucial to understand their distinct characteristics and applications.

What is a Flowchart?

A flowchart, at its essence, is a diagram that depicts a series of steps or actions in a sequential order.

It utilizes a combination of shapes, such as rectangles, diamonds, and ovals, connected by arrows to illustrate the flow of a process.

Each shape represents a specific element, such as a task, decision point, or start/end point, while the arrows indicate the direction of the workflow.

Flowcharts excel at breaking down intricate processes into individual steps, allowing for a clear visualization of the decision-making logic and potential branching paths.

This sequential representation makes flowcharts particularly valuable for algorithm visualization, where they can effectively communicate the flow of data and the logical sequence of operations within a computer program or system.

Benefits of Flowcharts

The primary advantage of flowcharts lies in their ability to foster visual communication and enhance process understanding.

By presenting information in a graphical format, flowcharts serve as powerful visual aids that transcend language barriers and enable teams to grasp the essence of a process quickly.

This visual representation is particularly effective in complex environments, where traditional text-based documentation may fail to convey the intricate relationships and interdependencies between various steps.

Moreover, flowcharts facilitate a shared understanding among stakeholders, fostering collaboration and enabling more informed decision-making.

By mapping out the flow of a process, potential bottlenecks, redundancies, or inefficiencies become readily apparent, paving the way for process optimization and continuous improvement.

How to Create a Flowchart

Creating an effective flowchart involves a systematic approach and adherence to best practices.

The first step is to clearly define the scope and boundaries of the process you aim to visualize.

Next, identify the individual steps or actions involved, as well as any decision points or conditional logic that may influence the flow.

Once you have a solid understanding of the process, you can begin constructing the flowchart by arranging the appropriate shapes and symbols in a logical sequence.

Each shape carries a specific meaning, with rectangles typically representing actions, diamonds symbolizing decisions, and ovals representing start or endpoints.

When designing a flowchart, it’s essential to maintain a consistent and intuitive visual language.

Adhere to industry-standard symbols and conventions to ensure that your diagram is easily interpretable by a wide audience.

Additionally, consider incorporating best practices such as minimizing crossing lines, aligning elements for clarity, and utilizing appropriate spacing and formatting to enhance readability.

What is a Process Map?

While flowcharts excel at depicting the sequential flow of a process, process maps take a more comprehensive approach by mapping out the inputs, actions, and outputs involved in a given workflow.

A process map provides a detailed, end-to-end representation of a process, often incorporating timelines and durations for each step.

Benefits of Process Maps

Process maps are invaluable tools for process improvement and workflow optimization.

Visualizing the entire process landscape, including inputs, actions, and outputs, enables a holistic analysis that can uncover inefficiencies, redundancies, or opportunities for streamlining.

This granular level of detail allows organizations to identify bottlenecks, allocate resources effectively, and implement targeted improvements that drive operational excellence.

Moreover, process maps serve as a powerful communication tool, facilitating cross-functional collaboration and fostering a shared understanding among stakeholders.

By providing a comprehensive view of the process, teams can better understand their roles, responsibilities, and interdependencies, ultimately enhancing coordination and alignment.

Creating Effective Process Maps

Developing an effective process map requires a structured approach and the right tools.

Begin by clearly defining the scope and objectives of the process you wish to map, as well as the stakeholders involved.

Identify the various inputs, actions, and outputs, and sequence them in a logical order, often following a horizontal or vertical layout.

When constructing a process map, it’s essential to leverage standardized symbols and conventions to ensure consistency and clarity.

Many organizations adopt industry-specific notation systems, such as the Business Process Model and Notation (BPMN) or the Integrated Definition for Process Description Capture Method (IDEF0), to ensure uniformity and facilitate seamless communication.

To streamline the process mapping effort, consider utilizing dedicated process mapping tools or software.

These applications not only provide a user-friendly interface for creating and editing process maps but also offer features such as collaboration, version control, and integration with other business systems, further enhancing efficiency and accuracy.

Key Differences Between Flowchart vs Process Map

While flowcharts and process maps share the common goal of visualizing processes, they differ in several key aspects, primarily in terms of their level of detail and ability to represent process complexity. So, let’s compare flowchart vs process map.

Use Cases for Flowcharts

Flowcharts excel in scenarios where a simplified, step-by-step representation of a process is desired.

They are particularly well-suited for software development, where they can effectively communicate the logic and flow of algorithms or program execution.

In engineering processes, flowcharts are often used to illustrate the sequence of operations or decision-making procedures involved in product design or manufacturing.

Project management is another domain where flowcharts shine, as they can provide a high-level overview of project phases, tasks, and decision points, facilitating effective planning and communication among team members.

Use Cases for Process Maps

Process maps, on the other hand, are invaluable tools for industries and applications that require a granular, end-to-end understanding of processes.

In business process mapping, process maps are essential for documenting and optimizing cross-functional workflows, enabling organizations to identify inefficiencies, streamline operations, and drive continuous improvement.

Manufacturing processes often rely on process maps to capture the intricate details of production lines, including inputs, outputs, quality checks, and interdependencies between various stages.

This level of detail is crucial for identifying bottlenecks, ensuring compliance with industry standards, and implementing lean manufacturing principles.

Quality management is another area where process maps shine, as they provide a comprehensive view of the various inputs, actions, and outputs involved in ensuring product or service quality.

By mapping out these processes, organizations can identify potential failure points, implement preventive measures, and continuously monitor and improve their quality assurance processes.

Flowchart Examples

IT network flowcharts are commonly used to visualize the flow of data and the various nodes or components involved in a computer network or system architecture.

These flowcharts can be invaluable for troubleshooting, optimizing network performance, and communicating complex network topologies to stakeholders.

Algorithm flowcharts are essential tools in computer programming and software development. They provide a visual representation of the logic and flow of an algorithm, making it easier to understand, debug, and communicate complex coding processes.

In the engineering domain, flowcharts are widely used to illustrate the sequence of operations involved in product design, manufacturing, or testing processes.

Engineering flowcharts can help identify potential bottlenecks, streamline workflows, and ensure compliance with industry standards and best practices.

Process Map Examples

Sales process maps are invaluable tools for organizations looking to optimize their sales workflows and enhance customer satisfaction.

By mapping out the various stages of the sales process, including lead generation, prospecting, proposal development, and closing, sales teams can identify areas for improvement, streamline communication, and ensure a consistent and efficient customer experience.

Product process maps are essential in the manufacturing industry, providing a comprehensive view of the entire product lifecycle, from ideation and design to production, distribution, and post-sales support.

These maps can help identify opportunities for cost optimization, quality improvement, and supply chain efficiencies, ultimately enhancing overall product quality and customer satisfaction.

Manufacturing process maps are crucial for documenting and optimizing complex production lines.

These maps capture the intricate details of each stage, including raw material inputs, quality checks, assembly operations, and final product outputs.

By visualizing the entire manufacturing process, organizations can identify bottlenecks, implement lean manufacturing principles, and continuously improve overall efficiency and productivity.

Choosing the Right Tool for Your Needs b/w Flowchart vs Process Map

Between flowchart vs process map, selecting the appropriate visual tool is crucial for driving workflow efficiency, fostering process understanding, and leveraging the power of visual aids effectively.

When to Use a Flowchart

Flowcharts are the ideal choice when you need to communicate a sequential process or workflow in a simplified, easy-to-understand manner.

They excel in scenarios where the primary objective is to convey the logical flow of steps, decision points, and potential branching paths without delving into intricate details.

If you’re working on software development projects, engineering processes, or project management initiatives, flowcharts can be invaluable in visualizing algorithms, operational sequences, or high-level task flows, facilitating effective communication and collaboration among team members.

When to Use a Process Map

Process maps, on the other hand, are the preferred tool when you need a comprehensive, end-to-end representation of a process, including its inputs, actions, and outputs.

They are particularly valuable in scenarios where a granular understanding of the process landscape is essential, such as business process mapping, manufacturing processes, or quality management initiatives.

If your goal is to identify inefficiencies, streamline workflows, or drive continuous improvement efforts, process maps can provide the level of detail required to pinpoint bottlenecks, allocate resources effectively, and implement targeted improvements.

Closing Thoughts on Flowchart vs Process Map

Flowcharts and process maps prove invaluable assets undoubtedly.

Mastering visual communication’s art and leveraging these gifted tools purposefully unleashes boundless optimization, collaboration, and evidence-guided resolution prospects.

Whether streamlining software development, enhancing production workflows, or enabling continuous quality improvements, discerning nuances between these visual aids equips informed routes and tangible successes.

Recall, that the key resides in judiciously selecting which visualization method precisely addresses specific scenarios while following design and implementation best practices.

Flowcharts and process maps differentiate functionally; each catalyzes situations distinctly.

By competently leveraging each visualization approach and the strengths of combined deployment, possibilities seem endless driving lasting transforms organizationally.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs