Six Sigma Black Belt

Black Belts gain a deeper knowledge of the analytics tool to optimize complex processes.

The Black Belt training is perfect for those who want to master Six Sigma techniques and strategies, lead top-quality projects, and mentor Green Belts. 6Sigma.us offers a “2+1 format” for in-person programs where the first two weeks are the Green Belt and the third week is focused on Black Belt concepts. This allows candidates with current Green Belt certifications to easily continue their journey without repeating training.

After successful completion of the Black Belt, one becomes eligible to carry out Six Sigma projects of their own. This sought-after certification is highly rewarded in the industry and holds a coveted place in the top organizations. Read to learn more about how Black Belt certification boosts your career and is often associated with top-tier salaries.

What is a Six Sigma Project?

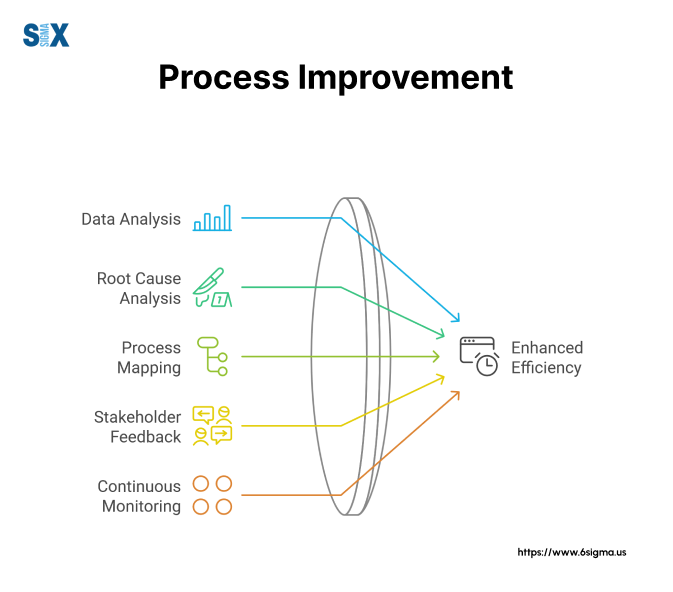

A Six Sigma project is a focused, data-driven initiative aimed at improving a specific process by reducing waste and variation. In essence, Six Sigma projects seek to achieve measurable results—whether that’s increasing efficiency, boosting customer satisfaction, or driving down costs.

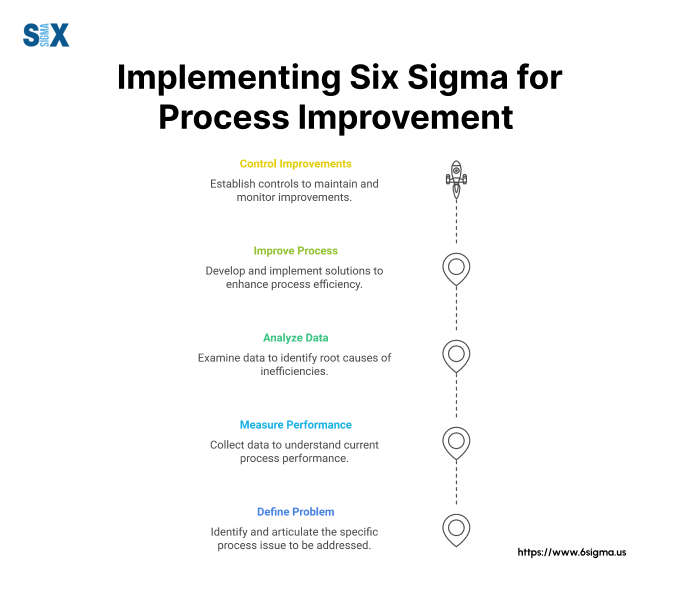

Through a standardized and structured approach called DMAIC (Define, Measure, Analyze, Improve, and Control), teams identify the causes of problems and implement sustainable solutions that are both cost-effective and impactful. They start by identifying the problem, evaluating the current condition, analyzing what can be done, executing changes, and finally creating the controls to sustain it. Through a Six Sigma Project, Green Belts and Black Belts are able to prove practical knowledge they learned during the training.

In other words, a Six Sigma Project is a smart, systematic way to solve business problems, save money, and improve quality, empowering teams to make data-backed decisions that lead to lasting success.

Course Outline – Six Sigma Black Belt

6Sigma.us offers Classroom, Virtual Instructor-led, and Online Self-Paced training & certification programs.

Classroom and Virtual Instructor-led Training

Six Sigma Black Belt training is for advanced process improvement leaders. The focus of the projects, at this level of proficiency, is typically on optimizing the process – establishing the best settings to maximize and provide predictable process performance.

Black Belt is conducted in either 4.5 days of live in-person training or two 3-day virtual-led training sessions.

Check out our current training schedule for In-person classroom & Virtual instructor-led training programs.

Black Belt Training Topics

- Law of Averages, aka Central Limit Theorem

- Advanced Measurement Systems Analysis

- Advanced Capability Studies

- Multiple Regression

- Between/Within Analysis, aka Nested ANOVA

- DOE Planning

- Full Factorial Experiments

- Fractional Factorial Designs

- General Factorial Designs

- Sample Size Calculation

- Optimization Designs

- Multiple Response Optimization

- Intermediate SPC

- Change Management

- Control Methods

Prerequisites: Green Belt training covering the DMAIC roadmap as well as analytical methods and familiarity with Minitab Statistical software. We will illustrate statistical analysis using Minitab during live training courses.

If you have completed Green Belt with another organization, please contact us to ensure your prior training is similar to the 6Sigma.us Green Belt program.

Online Self-Paced Training

There are no prerequisites for our Black Belt online program as White, Yellow, and Green Belt concepts are included.

Session 1 Green Belt Course Topics

- Six Sigma Program Overview

- Define Phase

- Six Sigma Deployment

- Process Variables Mapping

- Causes and Effects Matrix

- Failure Mode Effect Analysis (FMEA)

- Waste Identification

- Methods to Reduce Waste

- Introduction to Statistics and Graphical Analysis

- Graphical Analysis with Minitab

- Statistical Process Control (SPC)

- MSA

- MSA Exercise

- Capability Studies

- Session 1 Comprehensive

Session 2 Green Belt Course Topics

- Session 1 Review

- Multi-Vari Studies

- Hypothesis Tests

- T-Test / ANOVA

- Project Presentations

- Correlation & Regression

- Chi-Square

- Green Belt Wrap Up

- Session 2 Comprehensive

Session 3 Black Belt Course Topics

- Green Belt Review

- Review Exercise

- Central Limit Theory

- Project Presentations

- Advanced MSA

- Advanced Capability

- Multiple Regression

- Nested ANOVA

- DOE Planning

- Randomized Block Designs

- Full Factorials

- Black Belt Wrap up

- Session 3 Comprehensive

Session 4 Black Belt Course Topics

- Session 3 Review

- Review Full Factorials

- Fractional Factorials

- Exercise

- General Factorials

- Sample Size

- Project Reviews

- Optimization Designs

- Multiple Responses

- Change Management

- SPC Review for Control

- Control Methods

- Black Belt Wrap Up

- Session 4 Comprehensive

Note: SigmaXL Statistical Software is compatible exclusively with Windows starting on March 1, 2025. Minitab Statistical Software, on the other hand, is compatible with both Windows and Mac. While they offer a light web-based version for Mac users, we recommend using the full desktop application for the best experience for our training.

Get started with our Lean Six Sigma Green Belt Online Training (Self-Paced) training & certification program.

After attending this course, attendees will be able to:

- Apply advanced statistical tools and work with data of different types and distributions

- Apply different types of experiments

- Determine the sample size needed for experiments

- Apply the different types of optimization and how it affects processes

As a Black Belt, your mastery of Six Sigma techniques and strategies will help you lead top-quality projects and mentor Green Belts in your organization, where together you will identify and implement breakthrough improvements for enhanced bottom-line results.

Attendees will receive two certificates, one certificate for successfully completing the training and another certificate for successfully completing a live project, which will designate individuals as internationally recognized Six Sigma Black Belts.

6Sigma.us is proud to offer CEUs, PDUs, and PDCs for our training programs. We are accredited by IACET to offer CEUs, PMI® to offer PDUs, and SHRM to offer PDCs for our Black Belt for the successful completion of all training requirements. (PMI and the PMI Registered Education Provider logo are registered marks of the Project Management Institute, Inc.).

To receive an Adobe PDF of information about Black Belt classes from 6Sigma.us, please send an email with “Black Belt” in the subject line to blackbelt@dmaic.us.

What is a Six Sigma Black Belt?

A Six Sigma Black Belt is a highly skilled professional who leads complex improvement projects and serves as an organization’s resident expert in the Lean Six Sigma methodology.

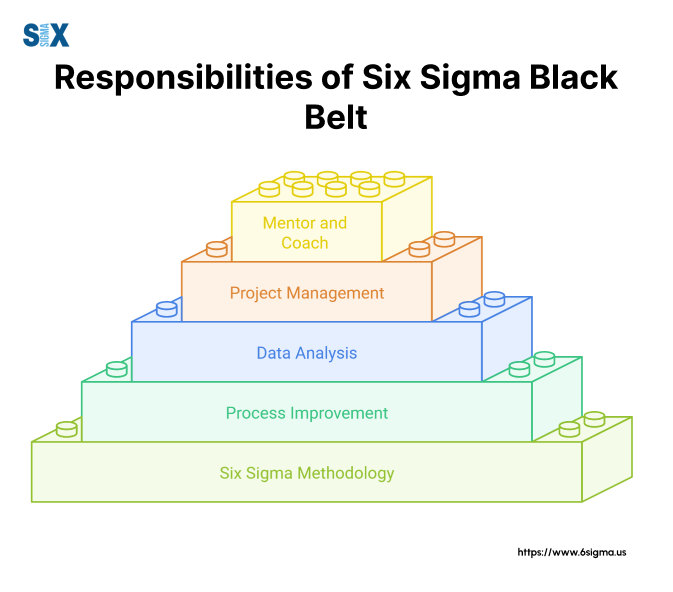

The Black Belt certification represents a deep understanding of Six Sigma statistical tools. As a Black Belt, you’re expected to:

- Complex process improvement projects

- Coach and mentor Yellow Belts and Green Belts

- Provide strategic insights to management

- Apply advanced statistical analysis to complex business problems

Advancing Your Six Sigma Certification Knowledge

The progression from Green to Black Belt is significant. While Green Belts are valuable team members, Black Belts take on a leadership role that requires a much deeper understanding of statistical tools and project management techniques.

These skills allow professionals to tackle more complex problems and lead larger, cross-functional teams.

Black Belts also need strong leadership and communication skills. The ability to explain complex statistical concepts to non-technical stakeholders is just as important as the technical knowledge itself.

Here’s a quick breakdown:

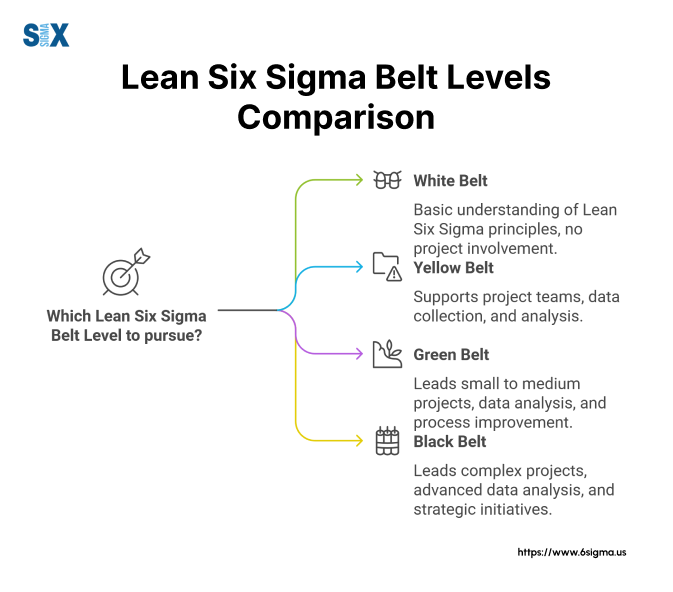

- White Belt: Entry-level certification, basic understanding of Lean Six Sigma concepts

- Yellow Belt: Project team members, can lead smaller projects

- Green Belt: Project leader members, can lead projects

- Black Belt: Project leaders, advanced statistical skills, full-time improvement roles

- Master Black Belt: Highest level, trainers and mentors for other belts

Six Sigma Black Belt Prerequisites

Let’s break down the key prerequisites you’ll need to meet.

- Green Belt Certification: You need to be a certified Green Belt before pursuing Black Belt certification. 6Sigma.us also provides the option to combine your Green Belt and Black Belt training, with no prerequisite. This option is ideal for a project leader who will be addressing a complex process on their first project.

- Educational Background: Professionals from diverse educational backgrounds, from engineering to business administration, can excel as Black Belts. Leadership skills are critical at the Black Belt level as they will often mentor Yellow and Green Belt candidates A basic understanding of statistical methods and the application of statistical software is beneficial; however, we cover the foundations in our Green Belt program for those taking the 2+1 format.

Six Sigma Black Belt Training & Certification Process

Now, let’s dive into the Six Sigma Black Belt certification process. This is where the rubber meets the road, and you start your journey towards becoming a certified Black Belt.

Training Options

When it comes to Six Sigma Black Belt training, you have several options:

- In-Person Training: If you prefer a traditional classroom setting, this training option is for you. We conduct numerous in-person training sessions. Check out our current training schedule.

- Virtual Instructor-led: For those who prefer live training, but from the convenience of your office or home, this is the go-to option. The best part, you learn via an interactive seminar with other professionals, taught by certified Master Black Belt. Check out our current training schedule.

- Live Private Training: if you are looking to train multiple employees, we can also deliver at your site or private virtual. Contact us for more information.

- Online Courses: We offer comprehensive online courses that allow you access 24/7 to learn at your own pace. This flexibility is perfect if you have a busy schedule. Check out our course.

Industry Presence and Roles of Six Sigma Black Belts

Six Sigma Black Belts revolutionize processes and drive significant improvements in organizations. This expertise is highly sought after, and for good reason. Let’s dive into the career landscape for certified Six Sigma Black Belts.

Industries and Roles

Six Sigma Black Belts are in demand across a wide range of industries.

Typical job titles for Six Sigma Black Belts include:

- Process Improvement Manager

- Quality Assurance Director

- Operations Excellence Leader

- Continuous Improvement Specialist

- Project Manager

- Business Analyst

Many of our former candidates have advanced to roles such as:

- Director of Operational Excellence

- Vice President of Quality

- Chief Operating Officer

- Master Black Belt

Case Study: Texas Department of Licensing and Regulation

The Texas Department of Licensing and Regulation (TDLR) is a growing state agency with increasing volumes of records to manage.

Previously, most of TDLR’s records were housed at one of the State’s primary storage and archive facilities. In 2012, when accounts receivable verified that the cost to store the agency’s records and documents had soared to intolerable levels, the staff was tasked to search for alternative solutions.

A. Robertson, currently the Knowledge Officer at TDLR (but a management analyst when the problem was identified), worked with his process improvement teammates to confront the challenge facing the agency.

At that time, Robertson had just begun training with 6sigma.us to earn his Six Sigma Black Belt certification. Early in his training, Robertson identified the “high storage cost for keeping records” as a prime Six Sigma project to conduct. The journey towards a solution began in 2012.

“We never had an official records management program, and this project was the catalyst for us creating one.”

A. Robertson

The challenge of reducing the volume of records kept and lowering the cost would be formidable. It was compounded by the transfer to TDLR of numerous programs from other state agencies by the Texas Legislature, actions that multiplied the records TDLR was obligated to maintain. Inheriting these records meant sorting and organizing them to identify which ones needed to be destroyed.

“We discovered that many of the agencies failed to purge records that had been eligible for destruction for years.”

A. Robertson

As the project evolved, it became apparent that the records management process needed to be made more efficient. One of Robertson’s process improvement teammates was a certified Six Sigma Master Black Belt who often referenced the Six Sigma methodology and its success rate.

Since tax dollars were at stake, the impetus was set in motion to make it right. After getting agency approval to take the Six Sigma certification training, Robertson launched the project.

Action

Research on storage options began. In 2006, the average cost for storage space had been $6900/yr, an expense that did not include imaging. By 2012 the same amount of space was $35K, with incremental increases in the number of records to be stored, as well as costs have accelerated.

The acceleration of costs was due in part to delivery fees, assessed at a rate of $21 each time a specific record or document was retrieved and delivered. Out of thousands of boxes stored, records were being pulled weekly for review.

TDLR also had boxes of records stored at other locations like public storage units, facility basements, premium office suites, and big wooden file cabinets on the floor throughout their facilities.

The expense to store records exceeded $41,960 each year, a total that did not include pickup and delivery, as well as other fees to the state’s primary storage and archive facilities, public storage units, and other premium office space. The number of boxes of records and documents to be stored totaled 6153, with each box having an estimated value of $90.

Here were some of the options explored:

- Microfilm: $391,157/year without monthly costs;

- Imaging: $559,923/year plus electronic storage and server costs;

- Storage Vendor B (Private): $73,920 plus monthly costs;

- Storage Vendor A (State) Other campuses: $42,000 plus monthly costs; and

- Public storage (Private): $21,600 plus monthly costs

Maintaining records at the state’s primary storage and archive facilities meant the way space was utilized had to change, and something had to be done about records eligible for destruction.

Originally, the name of this project was called the Records Retention Process, but it changed to the Records Management Project. Steps taken to make the needed changes included:

- Creating a high-level process map

- Listing inputs: Cost of boxes, labels, vehicles used, a retention schedule, inventory reporting system, storage facilities and personnel

- Identifying outputs: Accuracy of schedule, inventory list, reduction of documents, storage space, and cost

It was then established what could be controlled:

- Retention period

- How and where to store the records

- Number of personnel working on this

Various steps were then taken to ensure accuracy:

- Went to Library of Archives commission

- Pulled hundreds of sample boxes

- Manually counted the sheets of paper in every box

- Separated count by size of paper, oversized, standard or legal size

- Used Minitab software

- Entered dates

- Counted blueprints

Results

Championed by TDLR’s current executive director (who was at that time deputy executive director), the project had a team of approximately 18 people from all different departments including financial services, legal, and IT, as well as the process improvement team, which has now evolved into the Office of Innovation and Program Management. This team was responsible for several improvements:

- A systematic review of the retention schedule

- Reevaluation of original documents to determine if they could be modified (shortened)

- A decrease in the number of years records are kept

- Assigning a dedicated person to manage these records

- Acquiring an automated process that deletes unneeded and expired records

- Establishment of a system for submitting documents so they can be easily searched

The Texas Department of Licensing and Regulation exceeded its goals, using Six Sigma, to cut costs for storing records and documents.

Learn More About Our Six Sigma Certification Program

Before the project started, the estimated original goals were:

- A $21K reduction in costs

- A 50 percent reduction in storage space, from 4000 to 2000 sq. ft.

- A reduction in the number of records stored and held past their disposition date to zero

The numbers don’t lie! When this effort began, the cost to store 6153 boxes was $3496/month, or approximately $41,960/yr. By 2017, this figure had plummeted to $1018/month, or nearly $12,220/yr. Thus, the total upfront savings was approximately $90K!

As of February 2018, the number of boxes had dropped from 6153 to less than 300.

As a result of the project, not only was there a significant decrease in the cost of managing records, the amount of space used, and records kept past their disposition date, but two full-time records management officers (RMOs) were hired and a highly successful records management department was created and housed within the Office of the General Counsel.

A. Robertson was one of those RMOs. The other RMO is an expert in all aspects of records management and has been active in the management field for decades. Both were able to put their backgrounds, skill sets and areas of expertise together to create a strong sustainable records management program in a very short amount of time.

To bring about this transformation, Robertson used his statistics and analytics background, Six Sigma skills, and institutional knowledge of the agency, while Robertson’s colleague applied her 40-plus years of experience as a records management officer and administrator, certifications in contract management, and numerous certifications in records management.

Having created an extremely successful records management program at TDLR, this dynamic duo has gone on to speak at events and train other agencies in developing their records management programs.

Even with Robertson no longer in the role of RMO, the records management program is still yielding cost savings, reducing its carbon footprint, and making the whole managing of records process much more efficient.

Through his colleague’s efforts, process automation has begun, many of the physical records that need to be kept are being made electronic, and many of the electronic records that are eligible for destruction or are unnecessary are being deleted.

These steps reduce the amount of records that need to be physically stored, thus reducing the size of the rooms needed and lowering the costs to maintain them. They also formed the basis for a policy that defines how documents are to be archived and eliminated.

Challenges and Solutions in Implementation

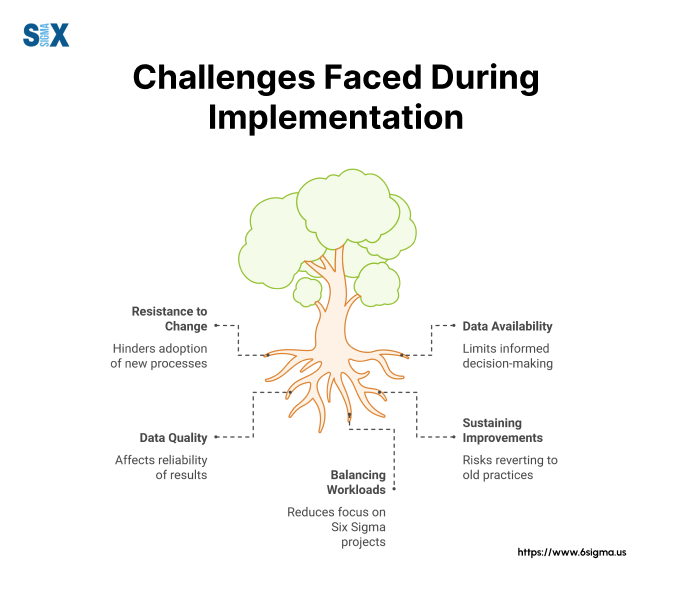

Here are some common obstacles and strategies to overcome the challenges faced during Six Sigma project implementation:

- Resistance to Change

Challenge: Employees often resist new processes or methodologies.

Solution: Involving stakeholders early in the project and communicating the benefits of change are crucial. Implement a change management program alongside our Six Sigma initiatives, which significantly improved adoption rates.

- Data Availability and Quality

Challenge: Many organizations struggle with data collection and integrity.

Solution: As a Black Belt, it’s essential to work closely with IT departments to ensure proper data collection systems are in place.

- Sustaining Improvements

Challenge: Initial gains can be lost if new processes aren’t properly maintained.

Solution: Implementing robust control plans is critical. We always emphasize the importance of the “Control” phase in DMAIC.

- Balancing Project Work with Regular Duties

Challenge: Black Belts often struggle to balance project work with their day-to-day responsibilities.

Solution: Clear communication with management about time allocation is crucial. In our training programs, we teach Black Belts how to effectively manage their time and prioritize tasks.

Best Practices for Successful Project Execution

- Align projects with strategic business goals

- Engage executive sponsors early and maintain their involvement

- Use data to drive decisions and validate improvements

- Celebrate quick wins to build momentum and support

- Continuously educate and involve team members in the process

Six Sigma Black Belts can overcome challenges and drive significant improvements in their organizations.

The skills and methodologies you’ll learn as a Black Belt are not just theoretical – they have practical, measurable impacts on business performance.

Get Started with Six Sigma Black Belt Training & Certification

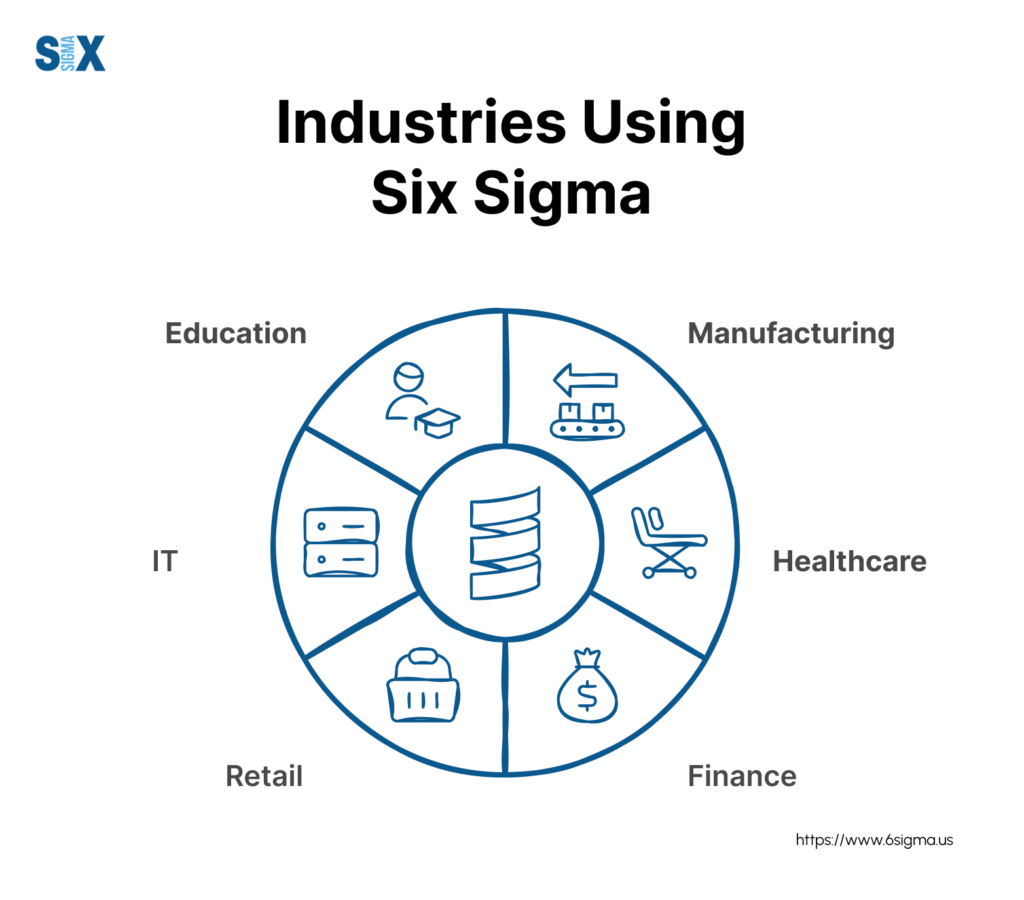

The demand for skilled Black Belts continues to grow across industries. Whether you’re in manufacturing, healthcare, finance, or technology, the principles of Six Sigma can help you drive meaningful change and achieve remarkable results.

As you contemplate your next professional move, we encourage you to seriously consider pursuing your Six Sigma Black Belt certification. It’s an investment in yourself that pays dividends throughout your career. The journey may be challenging, but the rewards – both personal and professional – are well worth the effort.

Remember, in the world of continuous improvement, learning never stops. Your Black Belt certification is not the end goal, but rather the beginning of an exciting journey of growth and impact.

Stay ahead of the curve and drive value in your organization as a certified Six Sigma Black Belt.

Start your Six Sigma Black Belt training & certification today!

-

The course was very easy to follow and understand in a logical manner. Navigating through slides is not very friendly, in the sense if one wants to review past content, etc.

Ana Isabel Perez Juarez |

5

-

It was very rigorous and engaging

Kevin Guthrie |

5

-

This was an excellent online work at your desired speed course. I would highly recommend it to others. Lots of great material and MiniTab examples.

Domenic Romeo |

5

-

The course was great and will be used for as long as I work in any job.

Andrew Jones |

5

-

I can not complain one bit. The material was well put together and explained.

Elgin Amboree |

5

-

Great course!

Bailey Mills |

5

-

The content of the course is relevant and can be applied to my working environment. Learning different analysis techniques was interesting and will definitely benefit me in future projects at work.

Heleen Olivier |

5

-

Loved the online flexibility.

Kathleen Henley |

5

-

I have had previous courses in lean, but not six sigma. i learned a great deal from this course. I need to practice in Minitab to gain more understanding of the models and how to set up the data so that I can use them on projects/process improvement efforts at work.

Kathleen Altier |

5

-

I like that the course was well structured and overall easy to follow. I had gotten my belt before with a different company, but that put too much emphasis on the Six Sigma tools without giving an adequate understanding of how the tools were used in the flow of the DMAIC process.

Ibaad Sadiq |

5

Training Schedule

Black Belt Certification & Training

[

]

Black Belt Certification & Training

[

]

Black Belt Certification & Training

[

]

Black Belt Certification & Training

[

]