Last Planner System: Revolutionizing Lean Construction Project Management

Developed by Glenn Ballard and Greg Howell in the 1990s, the Last Planner System is a lean construction technique that revolutionizes how projects are planned and executed.

LPS is a collaborative production planning system that empowers those closest to the work—the “last planners“—to actively participate in the planning process.

Key Highlights

- Origins and principles of the Last Planner System

- Five core components of LPS implementation

- Collaborative planning and reliable promise-making techniques

- Benefits: productivity, waste reduction, and workflow reliability

- Performance metrics: Percent Plan Complete (PPC)

- Advanced applications and integration with lean methodologies

- Future trends in Last Planner System adoption

Introduction to the Last Planner System

Last Planner System (LPS) stands out as a game-changer in construction project management.

Developed by Glenn Ballard and Greg Howell in the 1990s, LPS is a lean construction technique that revolutionizes how projects are planned and executed.

The Last Planner System is a collaborative production planning system that empowers those closest to the work—the “last planners“—to actively participate in the planning process.

These last planners are typically foremen, supervisors, and project managers who have intimate knowledge of the day-to-day operations on a construction site.

Principles of Lean Construction in Project Management

LPS aligns perfectly with lean construction principles, focusing on maximizing value while minimizing waste.

It’s built on the foundation of continuous improvement, respect for people, and the elimination of non-value-adding activities.

By integrating these principles, LPS creates a more reliable and efficient workflow, ultimately leading to improved project outcomes.

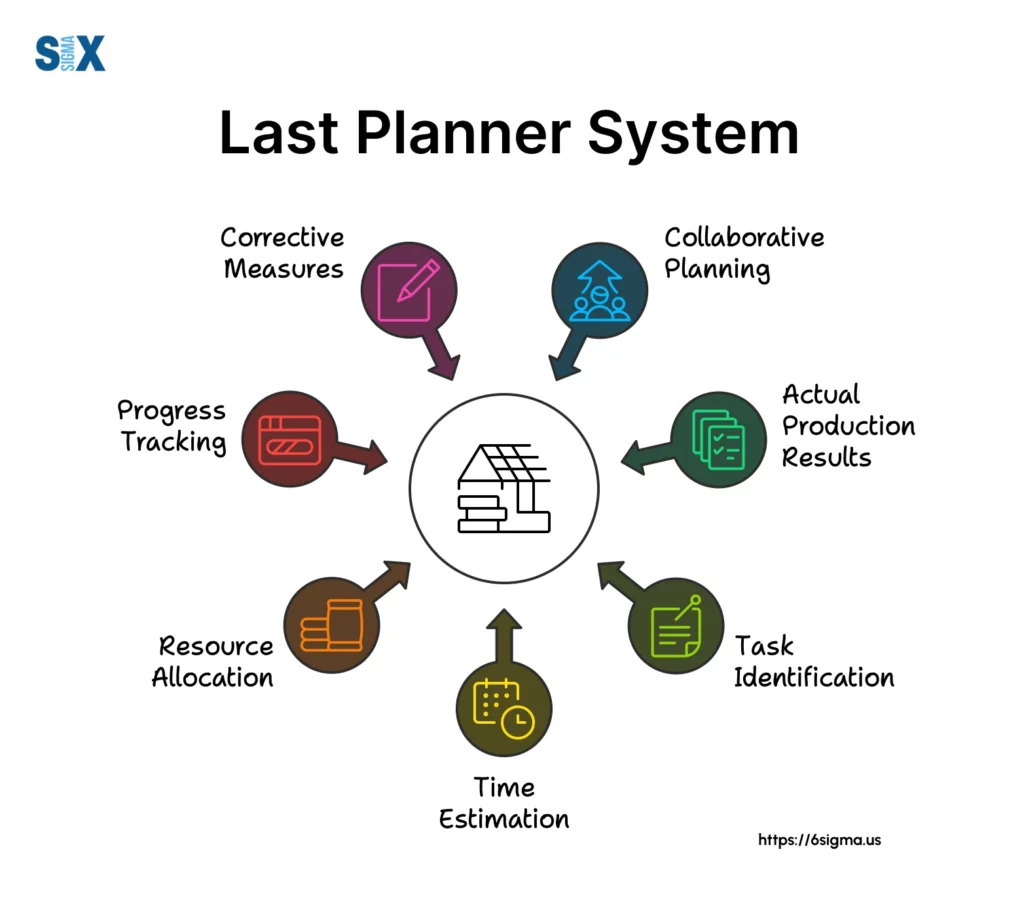

The system operates on five key principles:

- Plan in greater detail as you get closer to doing the work

- Produce plans collaboratively with those who will do the work

- Reveal and remove constraints on planned tasks as a team

- Make and secure reliable promises

- Learn from breakdowns

These principles form the backbone of LPS and guide its implementation across various stages of a construction project.

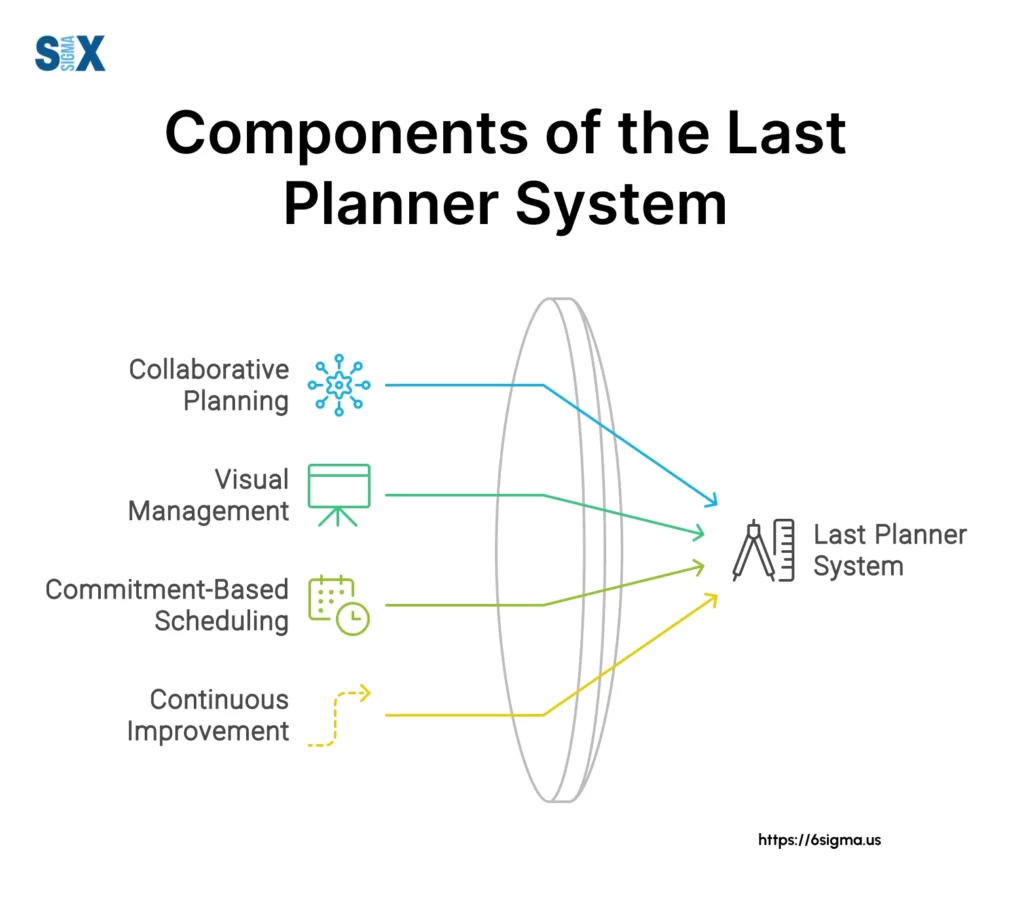

Key Components of the Last Planner System

Know the most important components of LSP

Master Scheduling and Milestone Planning

The first component of LPS is master scheduling and milestone planning. This is where we set the overall project goals and major milestones.

As a chemical engineer, I appreciate the importance of having a clear roadmap. In LPS, this roadmap is flexible and collaborative, allowing for adjustments as the project progresses.

Phase Scheduling and Pull Planning Techniques

Phase scheduling involves breaking down the master schedule into manageable phases.

Pull planning, a key technique in this stage, works backward from milestones to determine the sequence of activities needed to reach them.

This reverse engineering approach ensures that each task is tied to a specific outcome, eliminating waste and improving efficiency.

Look-ahead Planning and Constraint Management

Look-ahead planning typically covers a 6-8 week window and focuses on identifying and removing constraints before they impact the workflow.

This proactive approach to constraint management is crucial for maintaining smooth operations on site.

Weekly Work Planning and Commitment planning

Weekly work planning involves creating detailed plans for the upcoming week. This is where commitment planning comes into play.

Team members make reliable promises about what work they can complete, fostering accountability and improving workflow reliability.

Daily huddles and workflow optimization

Daily huddles are brief, focused meetings where team members discuss progress, identify issues, and make necessary adjustments.

These huddles are key to optimizing workflow on a day-to-day basis and ensuring that the project stays on track.

Implementing the Last Planner System

Know how to implement LPS into your organization.

Collaborative Planning and Reliable Promises

Implementing LPS requires a shift in mindset towards collaborative planning.

In my experience working with companies like 3M and Dell, I’ve found that fostering a culture of reliable promises is crucial.

This means team members commit to tasks they are confident they can complete, improving overall project reliability.

Visual Management Tools for Effective Implementation

Visual management tools play a significant role in LPS implementation.

These can include Kanban boards, color-coded schedules, and digital dashboards.

These tools enhance communication and provide real-time project status updates, much like the statistical process control charts I’ve used in Six Sigma projects.

Overcoming Challenges in Adopting the Last Planner System

Adopting LPS can be challenging, particularly in organizations with deeply ingrained traditional project management practices.

Common hurdles include resistance to change, lack of buy-in from all stakeholders, and difficulty in maintaining consistent application of LPS principles.

Overcoming these challenges requires strong leadership, continuous training, and a commitment to the lean construction philosophy.

Benefits of Using the Last Planner System

These are the benefits listed after using the LPS.

Improved Productivity and Waste Reduction

One of the primary benefits of LPS is improved productivity. By focusing on constraint removal and reliable commitments, LPS significantly reduces idle time and rework.

This aligns with the waste reduction principles I’ve applied in various Six Sigma projects across industries.

Enhanced workflow reliability and project control

LPS enhances workflow reliability by ensuring that prerequisites for each task are in place before work begins.

This improved reliability leads to better project control, reducing the likelihood of delays and cost overruns.

Better Collaboration and Problem-solving Among Team Members

The collaborative nature of LPS fosters better teamwork and problem-solving.

Daily huddles and weekly planning sessions create opportunities for open communication and collective problem-solving, much like the cross-functional teams.

Measuring Success with the Last Planner System

The Last Planner System employs key performance indicators like Percent Plan Complete (PPC) to quantify project reliability and efficiency.

Key performance indicators: Percent Plan Complete (PPC)

Percent Plan Complete (PPC) is a critical metric in LPS. It measures the percentage of planned activities completed as scheduled.

As a statistician, I appreciate the simplicity and power of this metric. A rising PPC indicates improving plan reliability and project performance.

Task Anticipation and Constraint Removal Metrics

Other important metrics include task anticipation (how far in advance tasks are planned) and constraint removal rate.

These metrics provide insights into the team’s ability to foresee and address potential issues before they impact the project.

Continuous Improvement Through Root Cause Analysis

LPS emphasizes continuous improvement through regular root cause analysis of plan failures.

This aligns closely with the DMAIC (Define, Measure, Analyze, Improve, Control) methodology I’ve used extensively in Six Sigma projects.

By understanding why plans fail, teams can implement targeted improvements and enhance overall project performance.

Advanced Applications of the Last Planner System

The Last Planner System exemplifies this adaptability, integrating seamlessly with value stream mapping and other lean techniques to enhance project outcomes across diverse sectors.

Integration with Value Stream Mapping

Value stream mapping, a lean technique I’ve often used in manufacturing settings, can be effectively integrated with LPS in construction projects.

This combination allows for a more comprehensive view of the project, identifying areas for improvement in both processes and planning.

Combining Last Planner System with Other Lean Methodologies

LPS can be combined with other lean methodologies such as 5S, Kaizen, and Total Quality Management.

In my experience, this integration can lead to synergistic effects, further enhancing project performance and team efficiency.

Adapting the Last Planner System for Different Project Types

While originally developed for construction, LPS principles can be adapted for various project types.

I’ve seen successful applications in software development, product design, and even in business process reengineering projects.

The key is to maintain the core principles while adjusting the specifics to fit the project context.

The Future of Last Planner System in Construction

The future of Last Planner System (LPS) looks promising, with evolving trends in lean project delivery.

We’re seeing increased integration of LPS with Building Information Modeling (BIM) and a growing emphasis on sustainability in construction planning.

These trends align well with the continuous improvement ethos of LPS.

Technology Integration

Finally, technology is playing an increasingly important role in the implementation of Last Planner System (LPS).

From mobile apps for daily huddles to AI-powered predictive analytics for constraint identification, technology is enhancing the power of LPS.

In conclusion, the Last Planner System represents a significant leap forward in construction project management.

Its principles of collaborative planning, continuous improvement, and waste reduction align closely with the lean methodologies I’ve applied throughout my career.

Last Planner System (LPS) will undoubtedly play a crucial role in shaping more efficient, reliable, and successful projects.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs