What are 7 Quality Management Principles? All You Need to Know

These days, reliably shipping top-notch products and services is mission-critical for businesses wanting to thrive long-term in ultra-competitive landscapes.

Achieving that demands a methodical quality management approach built on solid, evidence-backed principles and best practices.

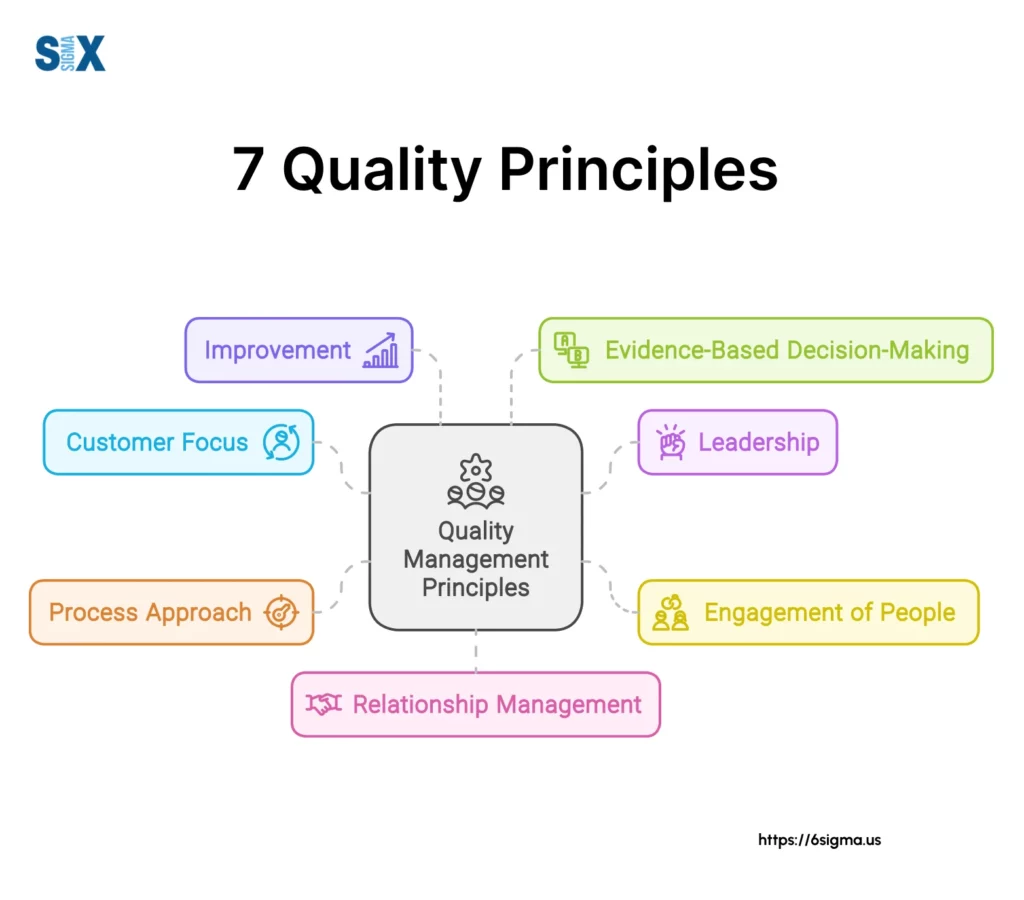

That’s where the 7 quality principles come in — a framework the International Organization for Standardization developed to help organizations pursue excellence.

These principles form the base for high-performing quality systems, charting a course for consistently exceeding customer expectations, streamlining processes, cultivating continuous upgrading, and ultimately fueling profits and expansion.

Whether starting from scratch or enhancing existing efforts, following internationally-vetted guidance brings the structure needed. Relying on proven methods instead of recreating the wheel paves the smoothest path toward customer commitment and sustainable success over the years ahead.

Key Highlights

- The 7 Quality Principles lay the groundwork for high performing quality systems.

- They were crafted by the International Organization for Standardization to help businesses boost performance and find lasting success.

- The 7 Quality Principles revolve around Customer Focus, Leadership, Motivating People, Process Awareness, Improvement, Evidence-Based Choices, and Relationship Management.

- Implementing these internationally-backed ideas can lead to happier customers, smoother operations, smarter decisions and stronger competitive spirit.

- Companies across many fields can adopt and apply these principles to cultivate a solid quality culture and spark never-ending upgrades. Whether starting from scratch or optimizing, it’s a globally proven path toward business excellence.

- The 7 Quality Principles offer clear guidance any organization can lean on. By following internationally trusted insight instead of re-engineering from zero, the path toward consistent quality and growth becomes that much smoother.

What are the 7 Quality Principles?

The 7 Quality Principles offer a foundation of core concepts for businesses to guide quality efforts. They’re outlined in the ISO 9000 family of quality standards.

Adopting the principles sets organizations up for lasting success by consistently fulfilling what customers need and helping them succeed.

The approach considers the full picture of quality management with a focus on strong leadership, motivating people, process awareness, continual upgrades, evidence-based choices, and mutually-beneficial supplier ties.

Properly applying the principles within an organization’s quality system optimizes performance and establishes a quality-focused culture.

Implementing them enables reliably crafting and shipping consistently high-grade products and services meeting or exceeding expectations.

This results in happier, repeat customers and cost-savings from fewer quality-linked issues. It can also secure an edge against competitors.

Overall the ISO-backed principles offer a globally-tested framework for any business to lean on, paving the smoothest path toward operational excellence.

Principle 1: Customer Focus

The first and most important of the 7 quality principles is maintaining a laser focus on customer needs and striving to exceed their expectations. An organization’s success depends entirely on its ability to consistently deliver products and services that provide value to its customers.

Understanding Customer Needs

The key to achieving customer focus is gaining a deep understanding of current and future customer needs.

This involves actively soliciting customer feedback through surveys, interviews, focus groups, and other methods. It also requires closely monitoring customer complaints and analyzing usage data and industry trends to anticipate evolving requirements.

Putting Customers First

With clear insights into what customers value most, organizations can orient their quality objectives, policies, and processes around fulfilling and surpassing those needs.

Customer focus should be embedded into the company’s quality culture and permeate every department and level of the business.

Examples of customer-centric practices include:

- Designing products/services based on voice-of-customer data

- Establishing robust feedback loops to quickly address issues

- Training all employees on the importance of customer satisfaction

- Continually evaluating performance through the lens of customer success metrics

- Making it easy for customers to access support and provide input

Principle 2: Leadership

Effective leadership is vital for driving a quality-focused culture throughout an organization. Leaders at all levels are responsible for establishing unity of purpose, direction, and creating an environment where people can become fully involved in achieving the organization’s quality objectives.

Some of the key aspects of leadership for quality include:

Vision and Planning – Top management must provide the vision, strategy, and planning to make quality a guiding principle of the organization. This involves defining the quality policy and objectives that align with the overall organizational goals.

Engagement and Support – Leaders need to engage with employees at all levels to communicate the importance of quality and ensure they have the proper training, resources, and motivation to fulfill quality requirements. Supporting quality initiatives through actions, not just words, is crucial.

Accountability – Leaders must hold themselves and others accountable for quality performance. This includes defining clear roles, responsibilities, and authorities related to quality processes.

Continuous Improvement – A cornerstone of quality leadership is driving a mindset of ongoing improvement. Leaders analyze quality data, question current practices, and promote innovation to enhance quality performance.

Customer Focus – Quality leaders ensure there is a strong emphasis on understanding current and future customer needs and aligning the organization’s processes to meet or exceed customer expectations.

Principle 3: Engagement of People

Engaged and empowered employees at all levels are essential for an organization to enhance its capability to create and deliver value. Engaging people allows their abilities to be used for the organization’s benefit.

To succeed in engaging people, an organization should:

Foster an Environment of Involvement and Empowerment

Create an environment that encourages involvement, empowerment, and personal development. Provide the necessary resources, training, and authority to involve and enable people to take accountability for their performance. Promote collaboration and knowledge sharing across the organization.

Communicate Roles, Responsibilities, and Accountabilities

Define, communicate, and understand the roles, responsibilities, and accountabilities of individuals and teams. This clarity helps people work more effectively and efficiently toward common objectives.

Recognize and Appreciate Contributions

Recognize and appreciate people’s suggestions, efforts, and achievements. This helps motivate engagement and commitment. Celebrate accomplishments as a team.

Enable Open and Constructive Dialogue

Promote open discussion and sharing of ideas, concerns, and opinions. Foster an environment of mutual trust and respect that allows constructive dialogue.

Provide Opportunities for Skills Development

Invest in building people’s competencies through education, training, coaching, and work experiences. This enables personal growth and enhances organizational capabilities.

Principle 4: Process Approach

The process approach principle states that desired results are achieved more efficiently when activities and related resources are managed as a process. This involves defining and managing a system of interconnected processes that function together to achieve the organization’s objectives.

The key benefits of taking a process approach include:

- Integrating and aligning processes to allow them to function in a coherent system

- Understanding how operational processes create value for customers

- Improving process performance and effectiveness through monitoring and analysis

- Managing process interactions and interdependencies across the organization

Implementing a process approach involves several key steps:

- Process Identification – Define the processes needed to achieve the intended results and outputs. Map out the sequence and interaction of these processes.

- Process Controls – Establish criteria and methods to ensure effective operation and control of processes. This includes monitoring, measurement, and related performance indicators.

- Process Ownership – Assign process owners who are accountable for each process and its performance. Empower them to make changes and improvements.

- Process Documentation – Maintain up-to-date documented information on processes to ensure consistent operation and facilitate improvements.

- Process Evaluation – Continuously evaluate and analyze processes based on data and information. Identify risks, constraints, and opportunities for optimization.

Principle 5: Improvement

Continuous improvement is essential for any organization to enhance its performance and create new opportunities. The fifth quality management principle focuses on improving the organization’s overall activities to achieve better results.

Successful organizations have an ongoing focus on improvement. They constantly analyze performance data and information to determine where value-adding activities can be improved and non-value-adding activities can be eliminated.

Improvement can be incremental through continual small steps or breakthroughs through innovation.

Some key aspects of the improvement principle include:

Improving Products and Services

Organizations should continually look for ways to improve their products and services to meet or exceed customer requirements and expectations. This involves gathering customer feedback, analyzing performance metrics, and implementing changes to enhance quality, functionality, and customer satisfaction.

Improving Processes

Processes are the backbone of any organization. Improving processes through techniques like process mapping, lean, and Six Sigma can optimize workflows, reduce waste and variation, improve efficiency and productivity.

Fostering a Culture of Improvement

An improvement culture encourages people at all levels to actively seek opportunities for improvement. Tools like suggestion systems, kaizen events, and quality circles can engage employees in continuously finding better ways of working.

Using Quality Tools

There are many quality tools and methodologies organizations can utilize for improvement, such as root cause analysis, statistical process control, design of experiments, and quality function deployment.

Setting Improvement Objectives

Clear objectives and targets for improvement focused on key areas like quality, productivity, costs, and cycle times provide the impetus and direction for improvement initiatives.

Principle 6: Evidence-Based Decision Making

In today’s data-driven business world, organizations need to base their decisions on factual evidence rather than assumptions or guesswork.

The sixth principle of quality management emphasizes the importance of evidence-based decision-making, which involves analyzing and evaluating data and information to make informed choices that drive continuous improvement and achieve desired results.

Evidence-based decision-making relies on collecting and analyzing relevant data from various sources, such as customer feedback, process measurements, market research, and performance metrics.

This principle encourages organizations to make decisions based on the logical and objective analysis of this data, rather than relying solely on intuition, experience, or subjective opinions.

By embracing evidence-based decision-making, organizations can:

- Identify and understand root causes: Analyzing data helps organizations identify the underlying causes of problems or inefficiencies, enabling them to address the root issues rather than just treating the symptoms.

- Minimize risks: Data-driven decisions reduce the risks associated with making decisions based on assumptions or incomplete information, leading to more informed and calculated choices.

- Improve processes: By analyzing process data, organizations can identify areas for improvement, streamline operations, and eliminate waste, ultimately enhancing efficiency and productivity.

- Drive innovation: Evidence-based decision-making can reveal new opportunities, trends, or insights that inspire innovation and help organizations stay ahead of the competition.

- Enhance customer satisfaction: By analyzing customer feedback and preferences, organizations can make decisions that better align with customer needs, leading to improved satisfaction and loyalty.

To effectively implement evidence-based decision-making, organizations should establish a culture that values data and encourages data-driven decision-making processes.

This may involve investing in data collection and analysis tools, providing training to employees on data analysis techniques, and fostering an environment where data-driven decisions are respected and encouraged.

Principle 7: Relationship Management

An organization and the parties involved in its supply chain are interdependent. Managing these interdependent relationships in a way that creates value for all parties is crucial for sustained success.

Effective relationship management involves:

- Establishing strategies and objectives for supplier relationships that are aligned with the organization’s policies and objectives

- Clearly defining the responsibilities, authorities, and roles within the supplier relationship

- Conducting performance reviews and driving continuous improvement initiatives with suppliers

- Openly sharing information, plans, and establishing clear channels of communication

- Resolving issues promptly through negotiation and compromise

- Recognizing supplier successes and good performance

- Collaborating on development activities and new projects

Strong supplier relationships based on mutual trust, respect, and value creation help an organization and its suppliers adapt to changing market conditions and constraints.

A focus on relationship management optimizes costs, quality, delivery, and responsiveness throughout the supply chain.

By proactively managing supplier relationships, an organization can leverage supplier competencies, innovations, and ideas to drive greater value.

Successful relationship management also helps mitigate risks, reduce defects and waste, and increase overall supply chain agility.

Implementing the 7 Quality Principles

Adopting the 7 quality principles outlined by ISO 9001 can help organizations achieve sustained success through improved performance.

However, implementing these principles effectively requires a structured approach and commitment from all levels of the organization. Here are some key considerations for implementing the 7 quality principles:

- Establish a Quality Management System (QMS): Develop a robust QMS that aligns with the requirements of ISO 9001 and the organization’s specific needs. The QMS should clearly define processes, procedures, and responsibilities for achieving quality objectives.

- Top Management Commitment: Strong leadership and commitment from top management are crucial for successful implementation. Top management should actively promote quality principles, provide necessary resources, and lead by example.

- Employee Training and Engagement: Engage employees at all levels and provide comprehensive training on the quality principles, the QMS, and their roles and responsibilities. Encourage employee participation and empower them to identify and address quality issues.

- Customer Focus: Implement mechanisms to gather and analyze customer feedback, understand their needs and expectations, and align processes to consistently meet or exceed customer requirements.

- Continuous Improvement: Establish a culture of continuous improvement by regularly reviewing processes, identifying opportunities for optimization, and implementing improvements based on data analysis and evidence.

- Process Approach: Define and document key processes, ensuring they are understood and followed consistently throughout the organization. Regularly monitor and measure process performance to identify areas for improvement.

- Evidence-Based Decision-Making: Collect and analyze relevant data from various sources, such as customer feedback, process measurements, and quality audits, to support informed decision-making and drive improvements.

- Supplier and Partner Collaboration: Foster collaborative relationships with suppliers and partners, ensuring they understand and align with the organization’s quality requirements and expectations.

- Quality Audits and Reviews: Conduct regular internal and external audits to assess the effectiveness of the QMS and identify areas for improvement. Review audit findings and take corrective and preventive actions as necessary.

- Communication and Awareness: Promote open communication and awareness of quality principles, objectives, and performance throughout the organization. Celebrate successes and share best practices to reinforce the quality culture.

Conclusion

Adopting the 7 quality principles provides a powerful framework for any organization to improve its processes, products, and services.

By keeping the customer as the primary focus, promoting leadership engagement, empowering employees, utilizing a process-based approach, embracing continuous improvement, basing decisions on factual evidence, and nurturing external partnerships, companies can drive operational excellence.

Ultimately, the 7 quality principles facilitate an integrated quality management system that aligns strategy, operations, and quality initiatives across the entire organization.

While implementing all 7 quality principles requires commitment and effort, even applying a few can provide significant competitive advantages through enhanced customer satisfaction, improved efficiency, reduced costs, and increased agility.

For organizations already certified to ISO 9001 or pursuing certification, adhering to the 7 quality principles is essential for developing a robust quality management system.

However, any business can benefit from adopting these universal concepts as a path toward sustainable growth and long-term success in today’s dynamic marketplace.

The key is to embrace quality management not as a siloed program, but as an organization-wide philosophy that guides decision-making, empowers employees, optimizes processes, and relentlessly pursues customer-driven value creation.

With commitment from leadership and engagement across all levels, the 7 quality principles can transform an organization into an industry leader in delivering exceptional products and services.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs