Critical Chain Project Management: A Comprehensive Guide

Effective project handling has become incredibly important for companies wanting to stay ahead in today’s environment. Among the many available methods, one approach gaining real traction is Critical Chain Project Management (CCPM).

Developed by Dr. Eliyahu Goldratt, CCPM stands on a groundbreaking framework known as the Theory of Constraints, offering a fresh view of managing work efficiently and maximizing resource usage.

Unlike traditional techniques primarily centered on individual tasks and rigid deadlines, CCPM takes a holistic outlook of the entire project cycle.

It acknowledges the inherent uncertainties and limits often facing projects. CCPM provides a structure for pinpointing and addressing the weakest links in the project “chain“, empowering teams to proactively navigate challenges that come.

CCPM questions conventional wisdom around adding extra time buffers to separate tasks, recognizing this can result in inefficiency and delays.

Instead, it advocates ambitious yet reasonable task estimates, removing redundant buffer periods, and thoughtfully positioning different buffers to safeguard the vital “chain” from disruptions.

This approach streamlines project flow while also cultivating urgency and accountability among members. Ultimately it drives increased efficiency and productivity overall.

Key Highlights

- Understanding the fundamentals of Critical Chain Project Management (CCPM) and its roots in the Theory of Constraints

- Exploring the core principles of Critical Chain Project Management (CCPM), including necessary condition logic, resource constraint management, efficient task estimation, and buffer management

- Analyzing the advantages of Critical Chain Project Management (CCPM), such as increased project throughput, reduced multitasking, and a focus on deliverables over internal milestones

- Addressing potential challenges and drawbacks, including the need for accurate estimates and perceived risks from compressed timelines

- Examining real-world case studies and examples of successful CCPM implementation across various industries

- Leveraging CCPM in conjunction with other project management methodologies (Agile, Lean, Waterfall) and tools

- Insights into emerging trends and the future of CCPM in the evolving project management landscape

Understanding Critical Chain Project Management

In project management, Critical Chain Project Management (CCPM) stands as a revolutionary approach that challenges conventional methodologies.

Developed by Dr. Eliyahu Goldratt, CCPM finds its roots in the Theory of Constraints, a paradigm-shifting philosophy that seeks to identify and mitigate the weakest links hindering system performance.

Critical Chain Project Management (CCPM) recognizes that projects are inherently complex, fraught with uncertainties and resource constraints that can derail even the most meticulously planned initiatives.

Unlike traditional project management methods that primarily focus on task-based structures and rigid deadlines, CCPM takes a holistic view, emphasizing the timely completion of the project as a whole.

The fundamental premise of Critical Chain Project Management lies in acknowledging that while individual tasks may be completed ahead of schedule, the overall project timeline is often dictated by the scarcity of critical resources or the interdependencies between tasks.

By identifying and addressing these constraints proactively, CCPM enables project teams to navigate through challenges with greater agility and efficiency.

One of the key distinctions between Critical Chain Project Management and traditional project management methods is the approach to task estimation and buffer management.

Whereas conventional methods often incorporate safety buffers within individual task estimates, CCPM advocates for aggressive yet achievable estimates, removing redundant buffer times.

Instead, it strategically positions project, feeding, and resource buffers to protect the critical chain from disruptions, fostering a sense of urgency and accountability among team members.

The Core Principles of Critical Chain Scheduling

One of the fundamental tenets of Critical Chain Project Management is recognizing that resource availability plays a pivotal role in determining project timelines.

Unlike traditional methods that often overlook resource constraints until later stages, CCPM integrates resource management from the outset.

Project planners meticulously assign resources to tasks, resolving any potential conflicts or bottlenecks that could impede progress.

To safeguard against unforeseen resource shortages, CCPM employs a strategic buffer management system.

Resource buffers act as early warning signals, alerting project teams when additional resources may be required, enabling proactive measures to ensure uninterrupted workflow.

Efficient Task Estimation

Recognizing the tendency of individuals to overestimate task durations as a means of building safety margins, Critical Chain Project Management advocates for a more aggressive approach to task estimation.

Project teams are encouraged to set task durations with a 50% confidence level, reflecting the time required to complete the task under optimal conditions.

This approach challenges team members to operate at peak efficiency and eliminates the redundant buffer times often embedded within individual task estimates.

Establishing the Critical Chain

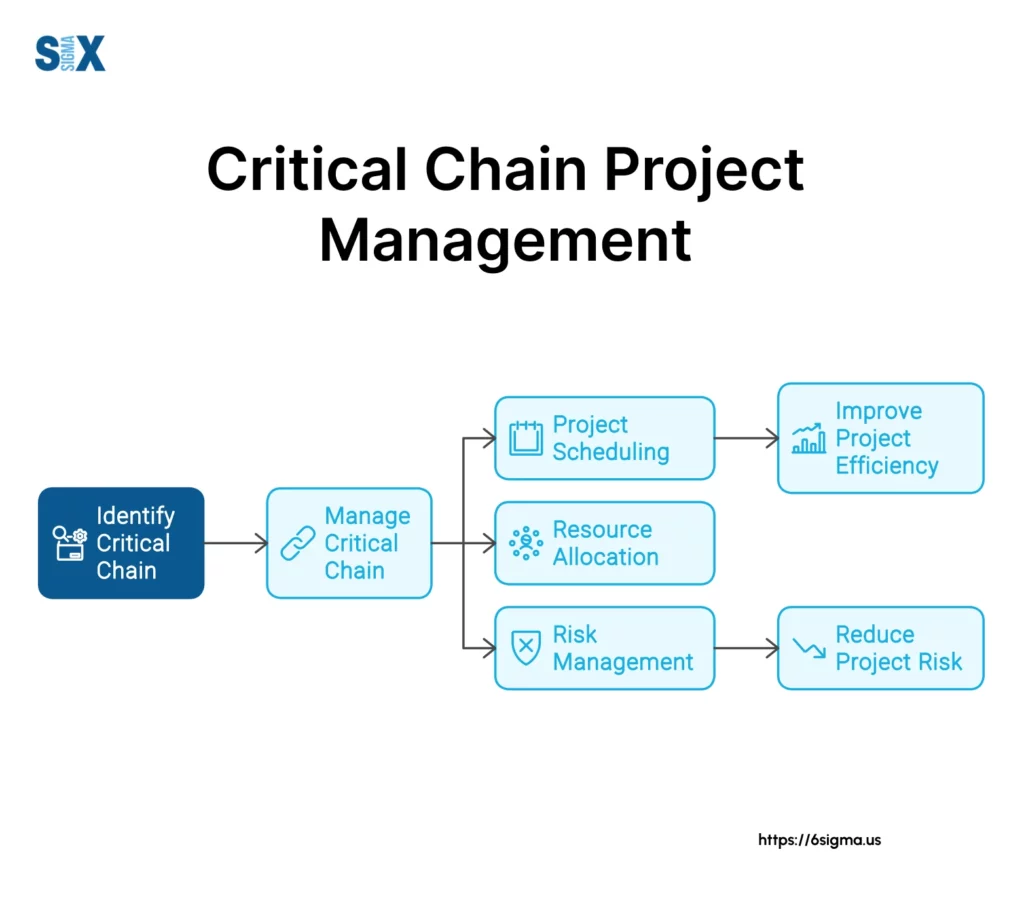

At the heart of Critical Chain Project Management (CCPM) lies the critical chain, representing the longest sequence of dependent, resource-constrained tasks that ultimately dictate the project’s completion timeline.

By identifying this critical path early on, project teams can prioritize and focus their efforts on the activities that directly impact the project’s success.

CCPM encourages a departure from traditional sequential scheduling methods, favoring a parallel approach whenever possible.

By carefully orchestrating the execution of tasks in parallel, project teams can capitalize on resource availability, accelerating project completion while minimizing idle time.

Implementing Buffer Management

While Critical Chain Project Management (CCPM) eliminates redundant buffer times within individual task estimates, it strategically incorporates three types of buffers to protect the critical chain from disruptions:

- Project buffers: These buffers are positioned at the end of the critical chain, providing a contingency reserve for the project as a whole. They safeguard against unforeseen delays, ensuring the project’s completion date remains intact.

- Feeding buffers: Also known as integration buffers, these are placed at the intersection points where non-critical chains merge with the critical chain. Their purpose is to prevent delays in feeding chains from impacting the critical path.

- Resource buffers: As the name suggests, they are designed to signal the need for additional resources before they are required on the critical chain. This proactive approach ensures that necessary resources are readily available when needed, minimizing potential bottlenecks.

By strategically positioning these buffers, CCPM creates a robust framework for managing project uncertainties and mitigating risks, increasing the likelihood of successful project delivery.

Benefits and Challenges of Critical Chain Project Management (CCPM)

Advantages

The adoption of Critical Chain Project Management (CCPM) can yield numerous benefits for organizations seeking to optimize their project management practices:

- Increased project throughput and efficiency: By eliminating redundant buffer times, encouraging parallel task execution, and fostering a sense of urgency among team members, CCPM enables projects to be completed more efficiently and with higher throughput.

- Focus on deliverables over internal milestones: Unlike traditional methods that emphasize hitting interim milestones, CCPM shifts the focus towards delivering the project outcome on time, aligning team efforts towards the ultimate goal.

- Reduced multitasking and improved flow: Critical Chain Project Management discourages context switching and multitasking, which can lead to productivity losses and quality compromises. Instead, it encourages team members to concentrate on one task at a time, fostering a smoother workflow and improved focus.

Potential Drawbacks

While Critical Chain Project Management (CCPM) offers numerous advantages, it is crucial to acknowledge and address potential challenges:

- Requires full resource and management buy-in: Successful implementation of CCPM hinges on the commitment and support of both project resources and management. Resistance to change or lack of buy-in can undermine the effectiveness of the methodology.

- Dependence on highly accurate estimates: CCPM relies heavily on the accuracy of task estimates, particularly when setting aggressive durations with 50% confidence levels. Inaccurate estimates can lead to unrealistic timelines and potential project delays.

- Perceived risks from compressed timelines: The aggressive nature of CCPM timelines may raise concerns among stakeholders accustomed to more conservative scheduling practices. Effective communication and risk management strategies are essential to address these perceived risks.

Critical Chain Project Management (CCPM) Case Studies and Examples

The effectiveness of Critical Chain Project Management has been demonstrated across various industries and project contexts. Notable examples include:

- Manufacturing: Companies like Boeing, Lucent Technologies, and Ricoh have successfully implemented Critical Chain Project Management to streamline their production processes, reducing lead times and improving resource utilization.

- Construction: Several construction firms have adopted CCPM to manage complex building projects, optimizing resource allocation and mitigating delays caused by resource constraints.

- IT and software development: Agile software development teams have integrated CCPM principles to enhance their delivery efficiency, aligning resource availability with project timelines and minimizing multitasking.

Comparative studies have shown that projects managed using CCPM often outperform those relying on traditional critical path methodologies.

Critical Chain Project Management (CCPM) projects tend to exhibit higher on-time completion rates, reduced cycle times, and improved resource utilization.

Leveraging Critical Chain Project Management (CCPM) with PM Tools and Methodologies

While Critical Chain Project Management offers a distinct approach to project management, it can be effectively integrated with other widely adopted methodologies and tools:

- Agile and CCPM: The principles of Critical Chain Project Management can complement Agile frameworks like Scrum and Kanban, facilitating efficient resource management and enhancing flow within iterative development cycles.

- Lean and CCPM: By eliminating waste and optimizing value streams, Lean practices align seamlessly with CCPM’s focus on resource optimization and constraint management.

- Waterfall and CCPM: For projects following the traditional Waterfall model, Critical Chain Project Management can be leveraged to enhance the planning and execution phases, ensuring resource availability and mitigating risks associated with interdependent tasks.

Project management software solutions have also evolved to support CCPM implementation.

Specialized tools offer features for building critical chain schedules, visualizing resource constraints, and monitoring buffer consumption.

By leveraging these tools, project teams can streamline the adoption of Critical Chain Project Management and gain valuable insights into project performance.

Successful CCPM adoption requires a strategic approach, encompassing comprehensive training, clear communication, and a culture of continuous improvement.

Project managers must foster an environment that embraces the principles of Critical Chain Project Management, encouraging team members to challenge conventional assumptions and embrace the methodology’s innovative practices.

The Future of Critical Chain Project Management

Critical Chain Project Management (CCPM) is poised to play an increasingly central role in how organizations tackle intricate initiatives.

Emerging trends and techniques carry the potential to further refine and enhance CCPM practices.

For example, advanced predictive analytics may allow more accurate task estimating and resource forecasting, lessening reliance on human-generated projections.

Additionally, constant monitoring and flexible rescheduling could dynamically modify buffer sizes and allocations, providing a more responsive and agile approach to management.

Furthermore, integrating Critical Chain Project Management with other rising methodologies like Design Thinking and Lean Startup principles could unlock novel ways to foster innovation and value.

Combining CCPM’s focus on constraint administration with design thinking’s user-centeredness and lean startup’s iterative cycles may heighten abilities to deliver projects aligned with customer needs while optimizing resource use.

As demands for efficient delivery keep rising, CCPM’s power to streamline processes, mitigate risks, and maximize resource use positions it as a compelling solution for organizations wanting a competitive edge.

By embracing Critical Chain Project Management principles and continually adapting to trends and techniques, project teams can attain new levels of performance and exceptional outcomes.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs